Apologies, because of some production issues, these items were omitted from our main SID 2017 report.

Among the many things Merck representatives were happy to discuss at their Display Week booth was the continuing development of bendable and free-form LCDs. Two weeks before the show, Merck had announced a collaboration with Flexenable U.K. “to accelerate the development of free-form displays, following a recent breakthrough by Flexenable with conformable, large area, full-color and video-rate organic [LCDs] on plastic. With a bend radius that can go below 30 millimeters, organic LCDs can satisfy the market needs for new use cases for example in automotive applications. In the near future organic LCDs can be curved around even more complex surfaces and shapes by combining Flexenable’s high-performance organic thin-film transistors with the innovative polymer wall LC technology from Merck KGaA, Darmstadt, Germany,” which was previously described in Display Monitor.

Merck doesn’t want the industry to forget that it is also very serious about OLEDs. Last year, the company opened a new production facility in Darmstadt that allows production capacity to be increased by a factor of five. The capacity of a Korean application lab is to be doubled this year.

Merck/EMD’s Bob Miller said the company’s plans to produce guest-host liquid-crystal architectural glass are on schedule. The manufacturing plant should be completed by the end of 2017, and production should start early in 2018. Whether the initial production will focus on privacy mode or solar control will depend on the initial customer. All Miller would say about that customer is that it will be in Europe.

The agreement that Merck would license Nanoco’s QD technology and manufacture dots was big news last year, with both companies indicating development was on the fast track. At Display Week, all Miller would say is “Nothing new on Nanoco.”

He did say that Merck developed the LC material for the Hella smart headlamp shown in the I-Zone. The material had to tolerate high temperatures and high luminous flux, and also had to work low temperatures. — Ken Werner

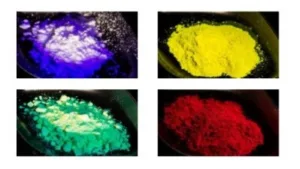

Merck wants the industry to know it is a serious developer of OLED materials. Emitters for vacuum thermal evaporation (VTE) are on the left; for printing applications on the right. (Photo: Merck KGaA, Darmstadt)