A new autostereoscopic (glasses-free) 3D display system is being developed at Beijing’s Tsinghua University, aiming to overcome the drawbacks of existing AS3D displays.

Glasses-free 3D today, using lenticular lenses, optical gratings or micro-lens arrays, suffer from a loss of image depth, low image resolution or shallow viewing angles. The new system uses what developer Hongen Liao calls a ‘light homogeneous emitting’ (LHE) approach, based on MEMS scanning units. A prototype has created animated 3D images with a perceived depth of more than 6m.

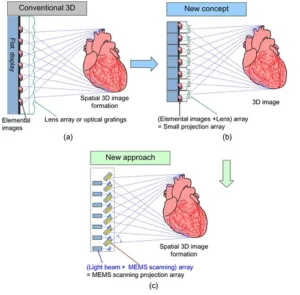

(a) Conventional 3D displays use elemental images and lens array or grating for 3D image generation. (b) 3D imaging can be interpreted as a method for displaying 3D objects at a desired spatial position by emitting light rays through a small projection array comprising an elemental image array and projecting lens array. (c) With the proposed 3D display approach, MEMS scanning units are formed in the same size as that of the small projection array arranged in (b). Light beams are always scanned two-dimensionally and repeatedly but intermittently transmitted to the viewing area.The system generates 3D images by driving multiple LHE MEMS scanning units. Each unit acts as an elemental pixel in the display. Following calibration, light from each MEMS unit is directed to a specific area in space. The result is a spatially-formatted 3D image for a viewer in that position. Different images can be delivered to different locations, thanks to the scanning action of the MEMS units, which enables the system to match the viewer’s position relative to the display. Image depth could be extended past 6m by using more MEMS units and enhanced precision calibration of the light rays.

A row of 16 MEMS scanning units were used in the prototype. Resolution was low; the MEMS units were placed in a single row, so “we [could] only display 3D-space images with the same number of pixels as there are units observed from one viewpoint”, said Liao. To extend the image, a multi-mirror system was used to effectively transform the 1D arrays into 2D. A 2D array is now being constructed, which will not require the multi-mirror system.

Liao noted that the performance and behaviour of the units is crucial to the system. He said, “We used custom-made MEMS units in our prototype LHE 3D display; but for the system to be put into commercial or industrial use, we do need the MEMS fabrication to become more compact, allowing real 3D images with high spatial and temporal resolution to become a reality… Digital micromirror device fabrication and related technology could be used to make MEMS units in the future”.

Further integration of light sources, colourisation units and MEMS scanning mirrors should improve the size and scalability of the display. Eventually, Liao envisages building a multi-mode display that includes 2D, binocular, multi-view and integral 3D imaging. Such a unit would be built by adjusting the MEMS scanning modes of the mirror(s) and controlling the input signals accordingly.

Future display development would involve working with DLP and laser projector manufacturers.

The research was published in the journal Nature: http://tinyurl.com/p5zvf79.