Kateeva believes that its Yieldjet Flex system has enabled a rapid transition from glass encapsulation to TFE in new OLED production lines. The company claims that its precision deposition solution for the TFE organic layer deposition process is fast, offers good planarization, few particle defects, high material utilization, good scalability, and easy maintenance. As a result, Kateeva claims to deliver dramatically higher TFE yields and lower mass-production costs, making the system a powerful alternative to vacuum evaporation technologies which they say had reached their technical limits.

Separately, ETNews of Korea has reported that both Samsung Display and LG Display are both looking at Atomic Layer Deposition (ALD) to improve the lifetime and performance of AMOLEDs by using the method to deposit the inorganic materials used in the layers that block the water and oxygen that OLEDs need to defend against by encapsulation. ETNews reports that the speed of ALD (a form of chemical vapour deposition [VPD]) is slower than the plasma enhanced chemical vapour deposition (PECVD) used at the moment, but the layers formed are more pure. The paper reports that LG is looking at using ALD for flexible OLEDs, while Samsung is already “working fast” to introduce ALD based on commercial production equipment.

Analyst Comment

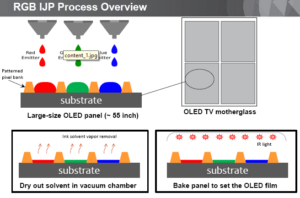

As we reported from SID (Kateeva May Enable Printing of OLEDs), Kateeva also believes that it has the technology to allow the inkjet deposition of RGB OLED materials, a long pursued target for OLED makers.

Kateeva said that it it can make ink jet deposition feasible.