I love writing about new technologies, in most cases they offer so much opportunity and so little is known about the real challenges the technology will have to face. I vividly remember discussions about the chance of LCDs ever being cost competitive with CRT. ‘Yes, they are great for a calculator, but a TV give me a break’.

All in all it took about a decade to prove these critics wrong. And still it took more decades to make a 4K UHD LCD TV that is so good that we are rarely arguing about mage quality anymore. Instead we focus on raising the bar for the display technologies in terms of new UHD standards. for example.

A similar situation exists with the introduction of OLED display technology. For a long time, we have been arguing over cost and lifetime, trying to make an assessment of when OLED will take over from LCDs. Other challenging display technologies were not able to get even close to mass adoption. But this may change now, with the appearance of micro LED display technology, which promises even better image performance than OLED displays.

Ever since Sony started showing its Cledis wall display and Apple invested in Micro LED technology by buying LuxVue, this topic has been slowly creeping up in the analyst coverage as well as tech blog news. So is this technology really worth the hype or is it just a little bump on the road to the reign of the OLED display?

MicroLED Could be a Challenger

I think it could be a real challenging technology at least in some specific areas. The key properties to watch out for are power demand (luminous efficacy), pixel density, brightness, color space, life time, and cost. All of those characteristics play out pretty differently for LED and OLED.

To be clear, I am not talking about Sony’s Cledis system in my analysis but about microLED displays that are creating a stand-alone display panel that directly compete with any LCD or OLED panel available today. The Sony Cledis wall could be viewed as an improvement over any existing LED wall by providing better images. Otherwise it closely follows the form factor and design of a LED wall. (and the drive architecture – Man. Ed.)

Let me first define how I view the landscape in this field. By no means do I believe I have it right and that any other view is incorrect. I just need to define the space so that I can explain why I am not sure at all how this will end.

Give Me Power

Let us start with the power demand. With the shift to more and more mobile devices that not only feature extremely bright high resolution display panels, but also high performance processors that rival the notebooks from just a few years ago, battery life is one of the key issues that could really shift the market share between brands. Now, assume that you can use a display panel that uses 20% less energy at the same brightness, with the other display properties being similar. This could be a very important factor for the success of a brand. Just look at the success of Samsung, that could arguably be seen as the consequence of the superior display technology used in its OLED panels. Since this publication is addressing the display industry, I would expect that I get a few bonus points for this viewpoint.

As a matter of fact, semiconductor based LEDs are beating OLEDs typically by some good margin and should have some advantage in mobile applications. This includes not only smartphones but all forms of wearable devices and even tablets.

From a perspective of brightness LEDs are still ahead, as their main adoption is in general lighting applications where high brightness is the most important aspect. If you wonder why LED has not made more inroads into light sources for projectors, it has to do with the etendue of the projection system. (My Etendue Story) In flat panel displays LEDs have long been the standard method of creating light.

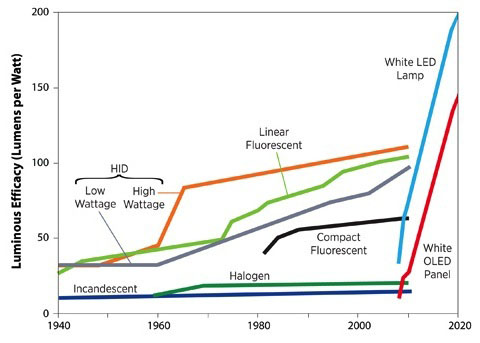

This chart shows the Luminuous Efficacy History up to 2012

This chart shows the Luminuous Efficacy History up to 2012

Pixel density is a question of how small I can make a pixel in a given display technology based on the design rules used. Since we want a certain display brightness as well, the light emission per area also plays a role in how small I can go. Since OLEDs are matrix displays, the smaller the pixel the harder I have to drive the OLED pixel to reach my desired brightness. This does have an effect on the life time and power consumption as well. Micro LED displays are different in this perspective as the actual LED chip is always very small and does not fill the entire pixel area anyway.

Color is Tricky

Color space is little more tricky. The emission spectrum of the OLED or LED is mostly defined by the material choices I make. A certain emitter type will have a wavelength that I can only shift a little. For example a blue emitter cannot be shifted to become a red or green emitter. This is true for OLED as well as LED. This characteristic is a question of material development. One day, LED is ahead and then OLED is ahead again to provide the best emitter wavelength. I believe that both technologies will be able to achieve their desired emitter characteristics. However, OLED, being based on organic chemistry, may have it easier to find the optimal material, as there are just many more organic compounds than semiconductor materials available.

The lifetime question is won by the inorganic LED, even though OLEDs may be just becoming ‘good enough’. If OLEDs really are getting good enough in this perspective, it may become a moot point. I just do not believe that OLEDs will ever beat an LED semiconductor in lifetime, under the same conditions.

Always Cost

That brings us to the question of cost and this is ‘where the rubber meets the road’. Whoever wins in this category may be taking home the whole prize. When we look at the numbers of units that use each technology it seems that the number game is slowly shifting in favor of OLED. However from a perspective of single LED manufacturing we have to include general lighting and that makes it clear that the number of single LEDs produced outnumbers OLED manufacturing by a wide margin. I know this is an unfair comparison, as OLEDs have many single pixels per display, nevertheless LED makers are still cranking out these insane numbers of single LEDs that all have to function and still contribute to the learning curve of making LEDs cheaper and better. (What LED Has to Do to Be Truly Disruptive)

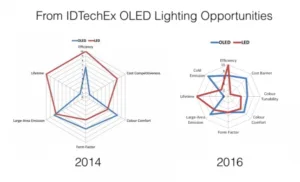

Since the current micro LED displays are still more or less a dream (with the exception of LED walls of course) we have to look at other applications to see if we have a chance to predict a winner in the race between OLED and LED. One interesting application is general lighting, where LED is ahead by a large margin. From an analytics perspective, IDTechEx has created a report analyzing the opportunities for OLED lighting. The following image compares the assessment of the two technologies in two separate reports from 2014 and 2016.

From the IDTechex OLED Lighting Opportunities Reports

The graphs are little difficult to compare, since IDTechEx has added a dimension in the 2016 report (cold emission) and changed one dimension from “Cost Competitiveness” to “Cost Barrier”. This means that if you have a high cost competitiveness you have a low cost barrier. This inverses the radar graph of course and as is shown OLED is still more expensive when compared to LED in general lighting applications. Other than that very little has changed between 2014 and 2016. LED is still ahead in certain areas and OLED is ahead in other areas. This matches up very nicely with my own assessment as described above. I take this as saying that in the last few years nothing has changed fundamentally.

Back to Displays

So how does this compare to the success chances of micro LED and OLED displays in display applications? These are two very different approaches to create the best flat panel display possible. One the one hand OLED follows the paradigm of the LCD-driven display world. The aim is to develop a display technology that can create a one to one replacement of a LCD panel on machines that can be mostly reused from LCD manufacturing lines. Micro LED is a complete different approach, using the existing mass production capacity of LED chips and placing these chips on a backplane to create the final display panel. Where OLED deals with very similar issues to those that LCD had to overcome, micro LED is completely different. Issue are about interconnect and pick and place technologies. The light emitting properties are already set in stone by choosing the specific LED chip.

As a consequence. the technical requirements of the micro LED development team has to be quite different from the team developing the OLED panel. By all means, the technical demands may be different and even easier for micro LED, however the development team has no sense of what it means to make a display panel. In a certain way, they have to learn what it means to make a display panel, which, in my eyes, is a clear disadvantage.

And the Award Goes To….

So, after all that, who has the edge in this race? From a timing perspective, OLED is certainly ahead, but this does not mean that micro LED is already out of the race. There are certain types of displays that require certain aspects of micro LED technology to create a better display. If this can drive the display manufacturing to a commercially viable position, all bets are off. The question is, will they get there fast enough? If yes, micro LED may indeed be the next big thing, and then again, maybe it won’t. – NH