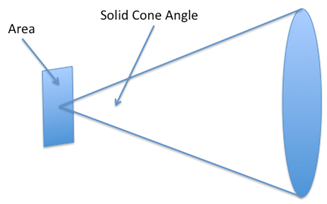

Etendue is a familiar word among optical engineers especially projection engine designers. It represents how “spread out” the light from a source is. The unit of measure is simply (sr * m²), the product of the solid angle and the area. The end result is a pure dimensional entity.

Putting it simply without complicated double integrals, it is:

Etendue = Area * Solid Cone Angle (? * Numerical Aperture ^2)

The closest related cousin is brightness, which is defined as Lumens/Etendue, where physical photons are added to the etendue system. A light source with very high brightness has lots of lumens and a very small etendue. In projector designs, it is important that the light sources are made as bright as possible with lots of lumens and very small etendues. The small etendue allows small imagers to be used, thus lowering the cost, as all imagers are fabricated on semiconductor substrates with yield inversely, and exponentially, dependent on area, which in turn, is proportional to etendue.

Both of these terms sounds simple, but I have gone through a lot of different experiences in dealing with etendue in the last 25 years and would like to share them with you.

The Eureka Moment

I encountered etendue when I started to work on projection displays over 20 years ago and I felt lucky that I had come to understand brightness about five years before that, while I was working on fiber optic illuminators. As a result, I was able to internalize the concept of etendue without much problem.

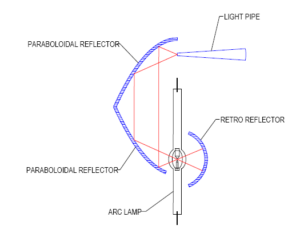

One of my jobs was to convince projection engine designers that the light sources I invented were brighter, initially with arc lamps, and later with LEDs. The basic principles used to improve the output were imaging, retro-reflection, and recycling. The end results were very simple. Brighter light sources provide higher screen lumens. Period. During the selling process, simply from the questions they asked and response to the answers I provided, I found that not all engine designers understood etendue. I started to think back on how I got to understand brightness to begin with, 25 years ago.

Before I worked with illuminators, coupling light from an arc lamp to small fiber optics, I was working on lasers and the coupling between the laser and fiber optics. It was quite different from coupling of light from arc lamps to fiber optics.

I learned about brightness. I knew all the equations and definitions. I claimed to know and understand brightness. But in the end, I did not really know it. I tried to create many designs which did not work until, one day, a flash of light came into my mind and “Eureka!” – I got it. It was not a continuous process, but a step function. I “did not” and suddenly I “did”, truly understand brightness.

Handicap can, sometimes, enable someone to acquire certain capabilities and knowledge that a perfectly normal person could not. While Stephen Hawking could not physically perform experiments himself on the lab bench, he was able to discover and invent with all the mental and thought experiments, and calculations that nobody else could. Andrea Bocelli, without his eyesight, focused on sound instead of light, became a world famous tenor.

Handicap can, sometimes, enable someone to acquire certain capabilities and knowledge that a perfectly normal person could not. While Stephen Hawking could not physically perform experiments himself on the lab bench, he was able to discover and invent with all the mental and thought experiments, and calculations that nobody else could. Andrea Bocelli, without his eyesight, focused on sound instead of light, became a world famous tenor.

In my case, the eureka moment came about while I was commuting back and forth to work. I was sitting in the car for an hour each way in the morning and in the evening. I was unable to perform any physical work with paper and pen, could make no lab experiments, and without a smart phone and/or a head-up-display in those ancient times, I was totally handicapped. Instead, I was able to enhance my mental thought process to a much higher level and envision many of the abstract concepts with a much deeper understanding and insight. I was able to make many calculations in my head, without decimal points of course, with results that I could use for making predictions and decisions. During these two hours every day on the freeway, I felt like a “saint” with heavenly thoughts.

Garden Hose versus Fire Hydrant

The fiber optics I worked with for the illuminator had a diameter of 0.4 mm with 0.7 Numerical Aperture (NA). The etendue value is 0.2. Other fiber optic systems were also designed with larger diameters and smaller NAs with etendue values in the neighborhood of about 10. The light sources used included arc lamps with 1 to 3 mm arc gaps, and LEDs with 1 mm by 1 mm to 3 mm by 3 mm square surfaces. The etendue range and the light sources designed, happened to be in the range of light sources and imagers I worked with for projection display using arc lamps, LEDs, and LCD, LCOS, and DLP imagers.

After that eureka moment on the freeway, I invented several reflector systems that preserved the brightness of the arc without loss of etendue and recycle LED light back to itself to increase brightness. For comparison, the etendue of the arc increased 10 to 20 times when the light from the arc was reflected by elliptical or parabolic reflectors. Thinking about etendue from this experience, I believe that many of those that needed to make the most of etendue transitioned from the “I did not” state to the “I did” state, prompted by some kind of unknown stimuli or insights. I also witnessed the transformation of the optical engineers I worked with in the past, with expertise in lenses, reflectors, and various optical software packages, from “I did not” to “I did”.

Later on, during my sales efforts, I created many ways trying to describe etendue and coupling from light sources to imagers in projection engines. The analogies included garden hose and fire hydrant, shooting water from a spray into a garden hose, from a small to a large garden hose, from a fire hydrant to a garden hose, etc.

In many cases, when we talk about etendue, we are actually talking about the average etendue, as the intensity profile of the light source, e.g. the arc lamp, is not uniform and the angular distribution is not lambertian. The brightness becomes the average brightness with the sum of all the photons collected from a specific emission area within a specific collection angle. For example, the brightness of the arc inside the arc lamp is not uniform. For a DC lamp, there is a very bright hot spot near the cathode that tapers off with distance along the lamp axis. For AC lamps, there are two bright hot spots, one near each electrode, with minimum brightness at the center between the electrodes.

the brightness of the light collected for the imagers is not represented by the highest brightness of the hot spots. Instead, the average brightness is determined by the amount of light collected from the whole region that is being shone onto the imager divided by the area of the region and the collection angle.

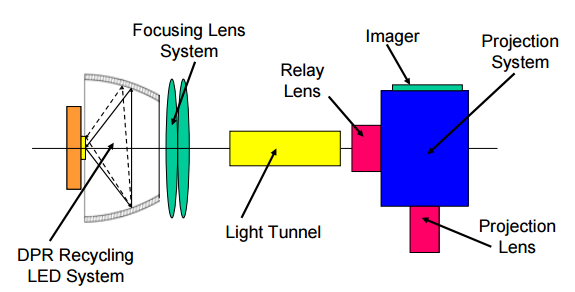

The light pipe or light tunnel used in many projection engines is a good example of the difference between hot spot brightness and average brightness. While the input and output etendue values of a non-tapered light pipe are the same, the input has a non-uniform intensity profile with hot spots and is converted to an output with uniform intensity profile without any hot spots

The World is full of Etendue

In the case of the fiber optic illuminator using fibers with an etendue value of 0.2 as described previously, the hot spot of the arc with a size of much smaller than 1 mm was imaged onto the 0.4 mm diameter input face of the fiber. Together with retro-reflection, the brightest fiber optic output was obtained.

This system uses the author’s Dual Parabolic Reflector (DPR) concept to channel the light for a pico-projection applicationIn the case of photonic lattice LEDs made by Luminus, the output angular intensity profile is not lambertian. The output is brightest along the optical axis and decreases with increasing angle. If only the light output near the optical axis is collected, the output will be brighter. As the collection angle increases, the average brightness will be the value and will be lower. Many projection engine designers understand this and as a result, with a given etendue of the imager, larger photonic lattice LED chips are chosen such that the average etendue of the LED is larger than that of the imager. But, if only a small collection angle near the optical axis is used, and “wastes” the high angle, low brightness output, the end result will be brighter than if smaller photonic lattice LED chips are used with a larger collection angle.

This system uses the author’s Dual Parabolic Reflector (DPR) concept to channel the light for a pico-projection applicationIn the case of photonic lattice LEDs made by Luminus, the output angular intensity profile is not lambertian. The output is brightest along the optical axis and decreases with increasing angle. If only the light output near the optical axis is collected, the output will be brighter. As the collection angle increases, the average brightness will be the value and will be lower. Many projection engine designers understand this and as a result, with a given etendue of the imager, larger photonic lattice LED chips are chosen such that the average etendue of the LED is larger than that of the imager. But, if only a small collection angle near the optical axis is used, and “wastes” the high angle, low brightness output, the end result will be brighter than if smaller photonic lattice LED chips are used with a larger collection angle.

As for laser phosphor systems, the laser output has an infinitely small etendue limited by the practical optical systems. As a result, the laser phosphor light source etendue is not limited by the laser itself, but limited by the amount of heat dissipated by the phosphor at the focused spot. The limitations are partly relieved by having very good heat sinking materials, and through the used of a rotating wheel. Further enhancements can also be made using a suspension of phosphor particles in a flowing liquid. (We reported on this development at the Display Summit [Wavien Wants to Cool Phosphor with Liquid (DS 5)– subscription required] – Man. Ed.)

The Philip HLD system provides a very high brightness light source for projection applications. The etendue of the output is determined by the area of the output face of the ceramic light pipe and the angular distribution of the light output. The conversion of blue light to green light is based on photoluminescence of the rare-earth dopants inside the ceramic light pipe. The light emitted is isotropic and only part of the light within the critical angle will be guided towards the output and the rest will be reflected back to the rod for reabsorption and reemission with efficiency losses. Without seeing the actual measured output angular profile, based on my understanding about photoluminescence, reabsorption, and reemission, I would predict that the output intensity profile would be sub-lambertian, if we consider the photonic lattice LED output from Luminus being super-lambertian. In theory, the HLD system could provide output with infinite brightness without any etendue limitations especially if the ceramic rod is pumped by the output of a very high power blue laser. The practical limitation will be the operating temperature limited by heat dissipation and saturation effects of the rare-earth dopants. Again, a suspension of the rare-earth dopant in a flowing liquid will raise the ceiling of HLD brightness.

Stay Tuned

I think we have enough Etendue for now. Please stay tuned for future articles.

Ken Li

Kenneth Li, Ph.D.

Dr. Li is an Independent Consultant and served as President and CEO at Wavien, Inc. He has published over 100 papers and presented at many display conferences. Dr. Li is the original inventor and developer of the Dual Paraboloid Reflector (DPR), LED Recycling Light Technology (RLT™), Laser Excited Phosphor Suspension, and 4-Dimensional Floating Image Displays with more than 95 issued and pending patents.