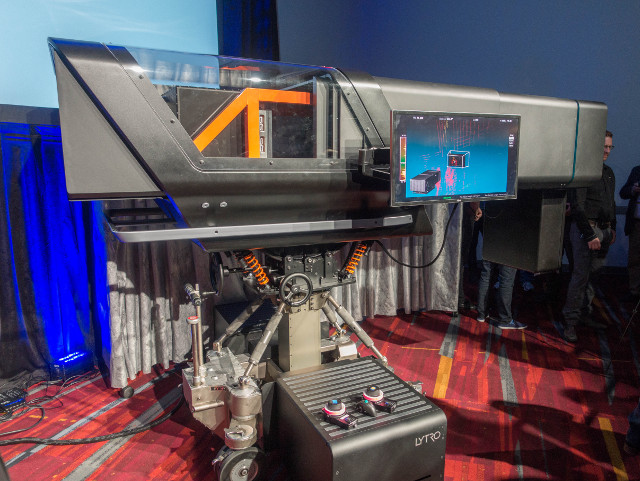

Fused fiber optics provider Incom has told us recently that they are a key component supplier to Lytro and their new cinema light field camera debuted at NAB 2016. What are fused fiber optics and why are they important for a light field camera, you ask? I was curious too, so I arranged a call with Michael A. Detarando, the president and CEO of the Charlton, Massachusetts-based company.

Fused fiber optics are a bundle of tiny fiber optics that are extremely closely packed and then melted together. They are an optical grade element that is often used to transfer light from one end of a cable to another and maintain the fixed relationship of the fibers all the way. That means light at any x-y point on the input exists at the same x-y point. This allows such cables to act as an imaging optical device. One of the more important configurations is called a taper, which means the diameter of the bundle is larger at one end than at the other.

Where is this useful? One area is protein crystallography. This application uses x-rays to examine the crystal structure of proteins. To do so, the x-rays impinge on a uniform scintillator plate that converts x-ray radiation to visible light. This light can then be received in a detector. In between the scintillator plate and the detector are two fused fiber optic assemblies. The first is a fiber optic bundle mated to the scintillator plate. This bundle tapers down to a smaller diameter and meets up with a second fused fiber optic plate that is mounted to the detector. Mounting a fused fiber optic to a sensor is quite tricky, so this two-part process helps with total system yields.

The key value of the fused fiber optics is the ability to transfer an image from one image plane to another with high fidelity. With tapers, you can do this for focal planes that have different periodicities.

Given my fused fiber optic knowledge, and experience with Incom, it’s easy to understand the why Lytro used Incom fused fiber optics in the light field camera. Likely, a large lens captures the light that must be transferred to an array of sensors, which is where fused fiber optics becomes of high value.

Lytro and Incom can’t reveal much in the way of details about this design, but it’s fair to assume that the 755 megapixel sensor backplane is composed of lots – probably somewhere between 50 and 100 – of sensors. The area of this sensor backplane is undoubtedly smaller than the area of the lens. Therefore, a tapered fused fiber optic solution makes sense.

Lytro showed images at NAB where there were something like 44 or 46 complete “views” of the scene. But you can’t take 755 megapixels and divide by 44 to get the resolution of each sensor (~ 2 megapixels). That’s because each sensor is capturing angular information as well. In other words, light at the center of the sensor came down the optical axis, where as light in the top left corner of the sensor came from the bottom right part of the scene. As a result, it would be surprising if each sensor was more like 10-15 megapixels each, rather than 2.

I had a chance to visit Incom a few years ago and tour its production facility. It is an incredibly complex and advanced manufacturing process to make fused glass fiber optic faceplates, tapers and other components. While profound in cinematic capabilities, it could also be pricey.

“The fused fiber optic business is small and serves a variety of specialty applications,” said Detarando. “When we met with Lytro and learn about their vision, technical capabilities and needs for fused fiber optic components, we were extremely impressed. As our companies share a passion for harnessing the power of light to provide unprecedented creative capabilities, Incom decided to go all-in to support Lytro’s camera development.”

Detarando noted that the Lytro light field camera project has driven Incom to produce, by far, the most sophisticated component the company has ever made, and Incom achieved their quality and production goals – made even tougher when Lytro asked Incom to half their delivery time to meet a deadline for an exciting new opportunity (like shooting a film and debuting it at NAB).

“Our talented, dedicated employees are the reason why we met the deadline with the needed components, and Incom continues to supply components to support Lytro’s plan to soon offer, and sell or lease, light field cameras,” noted Detarando. “This is a significant milestone for Incom, as it represents a new market opportunity for our technology.”

One interesting consequence of using fused fiber optics in a light field camera is the ability to compensate for any defects in the fiber optics. Making fused fiber optics with the high fidelity needed by Lytro is a towering challenge, but because it is a light field application, there is a lot of redundancy in the light rays captured by the many sensors. This allows algorithms to recreate the values affected by a defect by using information from other pixels.

Incom also has a new line of polymer fused fiber optics. These do not have the high optical characteristics of glass fused fiber optics, but they are much lighter and cheaper. It would not be unreasonable to assume that Lytro and Incom are looking at this possibility for future light field cameras.

And in fact, it may be necessary if they want to create a virtual reality light field camera – an area Lytro says they are working in. Here, the ability to capture a 360 degree spherical image is needed, which will mean multiple light field cameras closely packed together. But the optical requirements for each of these cameras would clearly be less demanding than the cinema camera where each pixel is shown on a big screen.

– Chris Chinnock