Image sticking and ‘burn-in’ are issues to some extent in all kinds of displays. In emissive displays, the issue is often called ‘burning’ and in transmissive displays such as LCDs, it’s usually known as ‘sticking’.

Even reflective displays such as TI’s DMD once suffered from pixel sticking when the corners of the micromirrors seemed to stick to the surface below, until TI put in small protrusions that acted as a kind of spring to bounce the corner away from the surface.

Emissive displays degrade because of the effect of the drive current and emitted photons on the material itself. The problem for LCDs is that they work by applying a charge to the molecules of LC material to control the light going through the material. Over time, the molecules can start to build up a residual charge and start to mis-align from their optimum positions, changing the light transmission.

OLEDs, as emissive devices, are also subject to burn in under some conditions. There have been lots of different tests performed by reviewers (e.g. rtings.com) and by academic institutes (A paper (51.3) was given at the SID Display Week Symposium this year that looked at colour shift in HDR OLEDs).

Ideally there should be a way for display makers to specify how their displays would perform in this area and for set makers to be able to specify their requirements, that is to say, measurements to allow management.

IDMS 1.03 Was Monochrome

The original IDMS V1.03 had a test to measure ‘Residual Image’ performance but it was based on test patterns that were monochrome, using a checkerboard pattern. That was fine for LCDs because, as far as I know, the sticking was not related to a specific colour – the same LC material was controlling every pixel. However, a challenge for OLED is that the materials for red, green and blue are very different in performance and lifetime, with blue especially weak still.

The IDMS V1.03 Checkerboard pattern

The IDMS V1.03 Checkerboard pattern

A second issue is that there are both short term and long term sticking effects. Emissive display burn-in tends to be long term but LCD effects can be both short term and long term. The burn-in process is typically mitigated by making the burn ‘even’ between the different colours, but LCD sticking can sometimes be reversed by applying voltages to reverse residual charging effects.

The new IDMS standard, introduced last week (ICDM Has IDMS V1.1 and Other Acronyms) has addressed these issues. The first change is in section 10.8 ‘Color Residual Image Methods’.

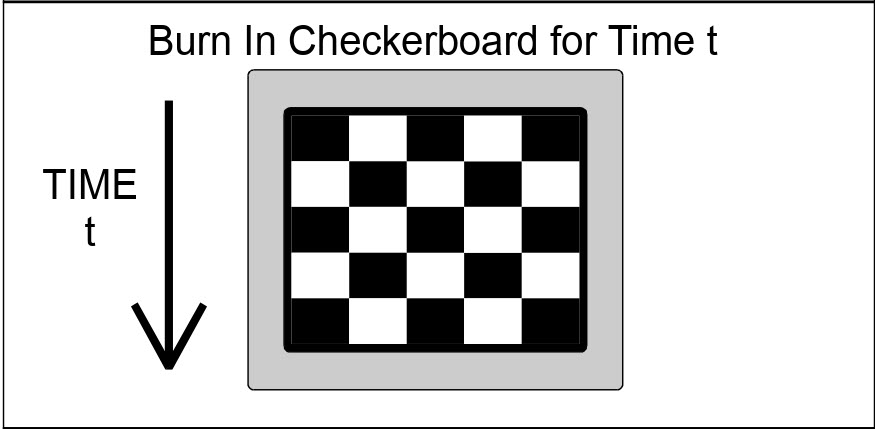

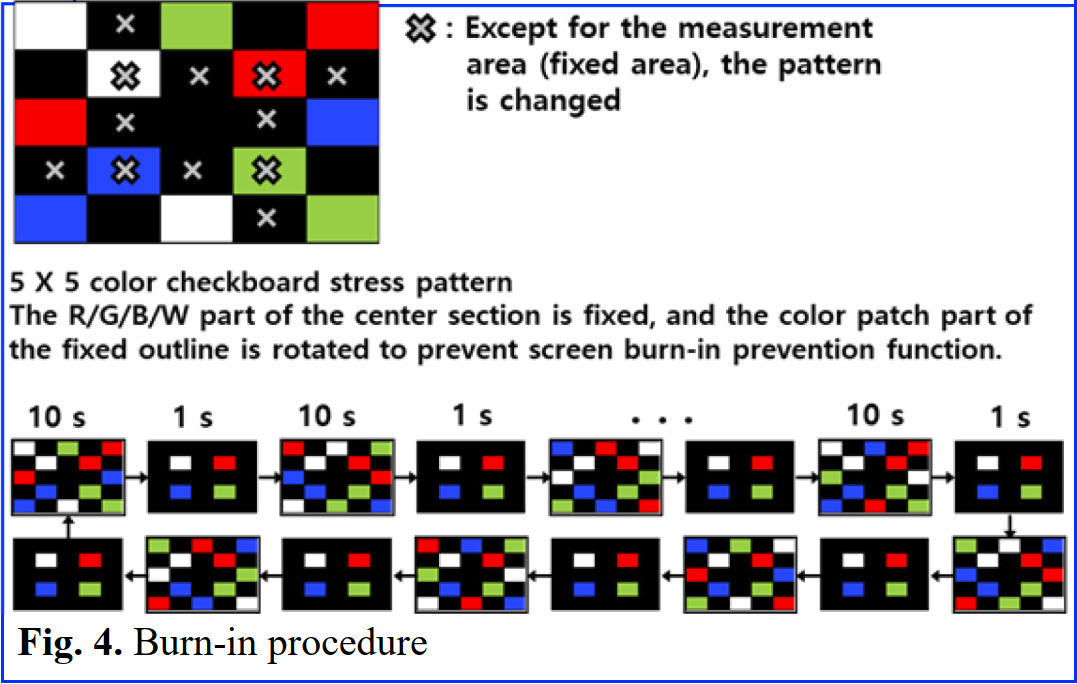

The new procedure sets out a sequence of different colour chequerboard patterns that are designed to include some fixed colours and some variable colours on different parts of the display.

The new IDMS V1 1 patterns include fixed and changing patches.

The new IDMS V1 1 patterns include fixed and changing patches.

First, there is a process for measurement to define the uniformity before the test. Then the patterns are displayed for the test time period. (the time period is not defined as it may depend on the likely application. Smartphones are not used for that many hours, but public displays are often used for very long periods. The IDMS does not set out what is good enough or not, or a pass/fail, it just sets out how to get reliable measurement data).

The colour values (including 25%/50% and 75% signal levels) for SDR and HDR signals are set out and also the metadata for PQ-based HDR displays. At the end, the final measurements are taken and compared with the initial conditions.

Short Term vs Long Term

As well as the longer term test (10.8.2), there is a short term test (10.8.1). The procedure takes account of the need to warm up the display to working conditions before testing. The process also sets out the speed needed for making the tests, before effects ‘wear off’.

Those tests take into account the needs for non-video displays, but for TV and other displays showing video, the kinds of signal level and images are quite distinct, so Chapter 10.9 of the new standard describes procedures to measure video-related image retention and specifies the use of standardised video content. TV also includes fixed images such as channel logos and idents, so pattern tests are also specified in the standard and an option is given to include a specific logo in the test.

Makers have developed technology to mitigate image retention, so the standard allows these to be used and reported to make the tests more realistic to how TVs would be used.

As well as reporting how the tests are done, the standard specifies how the results of all these tests are presented.

The IDMS is available for free download here. (BR)