Mattrix Technologies was previously NVerPix – a company that we reported on in 2016 when it announced its technology (and won the iZone award nVerpix Shows Breakthrough OLED Pixel Design) However, the founders fell out with the VC that was funding the firm, so development stalled. However, the IP has now reverted to the University of Florida because it was not being exploited. The University has re-licensed the IP to Mattrix, which is a new start-up. Dr. Max Lemaitre who spoke at the event is the founder and CEO and all the inventors of the technology are involved in the company and the company has a relationship with senior display specialists in Korea.

Mattrix Technologies was previously NVerPix – a company that we reported on in 2016 when it announced its technology (and won the iZone award nVerpix Shows Breakthrough OLED Pixel Design) However, the founders fell out with the VC that was funding the firm, so development stalled. However, the IP has now reverted to the University of Florida because it was not being exploited. The University has re-licensed the IP to Mattrix, which is a new start-up. Dr. Max Lemaitre who spoke at the event is the founder and CEO and all the inventors of the technology are involved in the company and the company has a relationship with senior display specialists in Korea.

The challenge for OLEDs is the complexity of the pixel structure and the quality of the drive transistor. No transistor can work well with long term high currents, Lemaitre said. That seems to be a long term barrier. One solution is to build compensation into every pixel and Samsung has up to seven transistors per pixel – it’s amazing at mobile phone size, but impossible in large displays. LG Display has used oxide transistors, but that has turned out to be difficult to do economically.

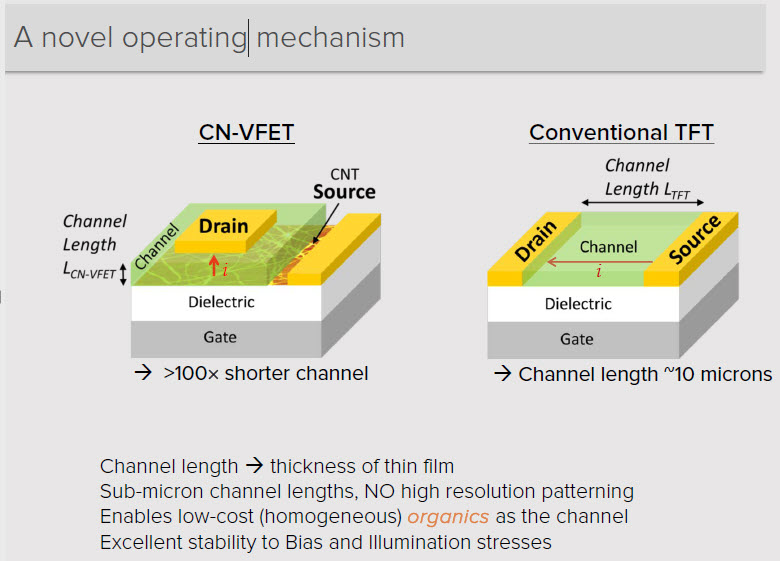

Mattrix has a new way of making the OLED transistor so the pixel can be thought of as a ‘gated OLED’. It uses a layer of carbon nanotube film. That means that the current flows away from the interface and that reduces the frame density of current. The current is decoupled from the oxide traps, allowing stable performance from an organic transistor. Simpler materials give performance better than any current technology, Lemaitre claims.

The result is a much simpler backplane, which should mean better yields at lower cost. It is also suitable for flexible displays.

The other advantage is very high aperture ratio. Currently around 70% has been demonstrated, but up to around 88% should be possible, the company told us in a discussion. The source electrode is transmissive, so top emission is not a problem which should be a significant advantage in OLED applications.

Lemaitre said that the company has sixteen patents, but they are really central and cover the core architecture. The company is working with a couple of panel makers and manufacturing is basically the same as other TFT manufacture, except for the CNT layer, but Mattrix has a couple of solutions (pun intended) for that. One uses spraying and the other uses slot die coaters. Both methods are being developed.

The key advantage of the technology is the possibility of significantly boosting yields by reducing backplane problems.

Mattrix is in Series A funding and has a plan to get into mass production with a demonstration within a couple of years. It is just interested in technology licensing and will not go into production itself.