FlexEnable was represented by its CEO, Chuck Milligan. He explained how the company had developed a G3.5 fab in Dresden, Germany, because of the scale of its investment (under the name, Plastic Logic). Unfortunately, the company hit up against Amazon’s Kindles and the iPad and could not meet the product requirements using its plastic electronics. Now, the company has gone back to being a technology company and it is focusing on organic substrates for LCDs. The Dresden fab has continued as a producer of plastic electronics, and Flexenable was spun out as a technology provider that has 18 years experience in plastic electronics.

FlexEnable was represented by its CEO, Chuck Milligan. He explained how the company had developed a G3.5 fab in Dresden, Germany, because of the scale of its investment (under the name, Plastic Logic). Unfortunately, the company hit up against Amazon’s Kindles and the iPad and could not meet the product requirements using its plastic electronics. Now, the company has gone back to being a technology company and it is focusing on organic substrates for LCDs. The Dresden fab has continued as a producer of plastic electronics, and Flexenable was spun out as a technology provider that has 18 years experience in plastic electronics.

The transistors that it can make are “working well” and Milligan highlighted that its process can be done at 100º C. The company is working on displays that need the flexibility and robustness that it can provide and it is also developing sensors.

The business model is to work with existing fabs, but that can be tricky as there is work to do to convert from other LCD technologies. The company has also worked on the end users to put pressure on their supply chains and it is working with Truly coming on board as a partner to make displays in its Gen 2.5 and Gen 5 fabs. Flexenable has customers that want to buy the finished displays, already.

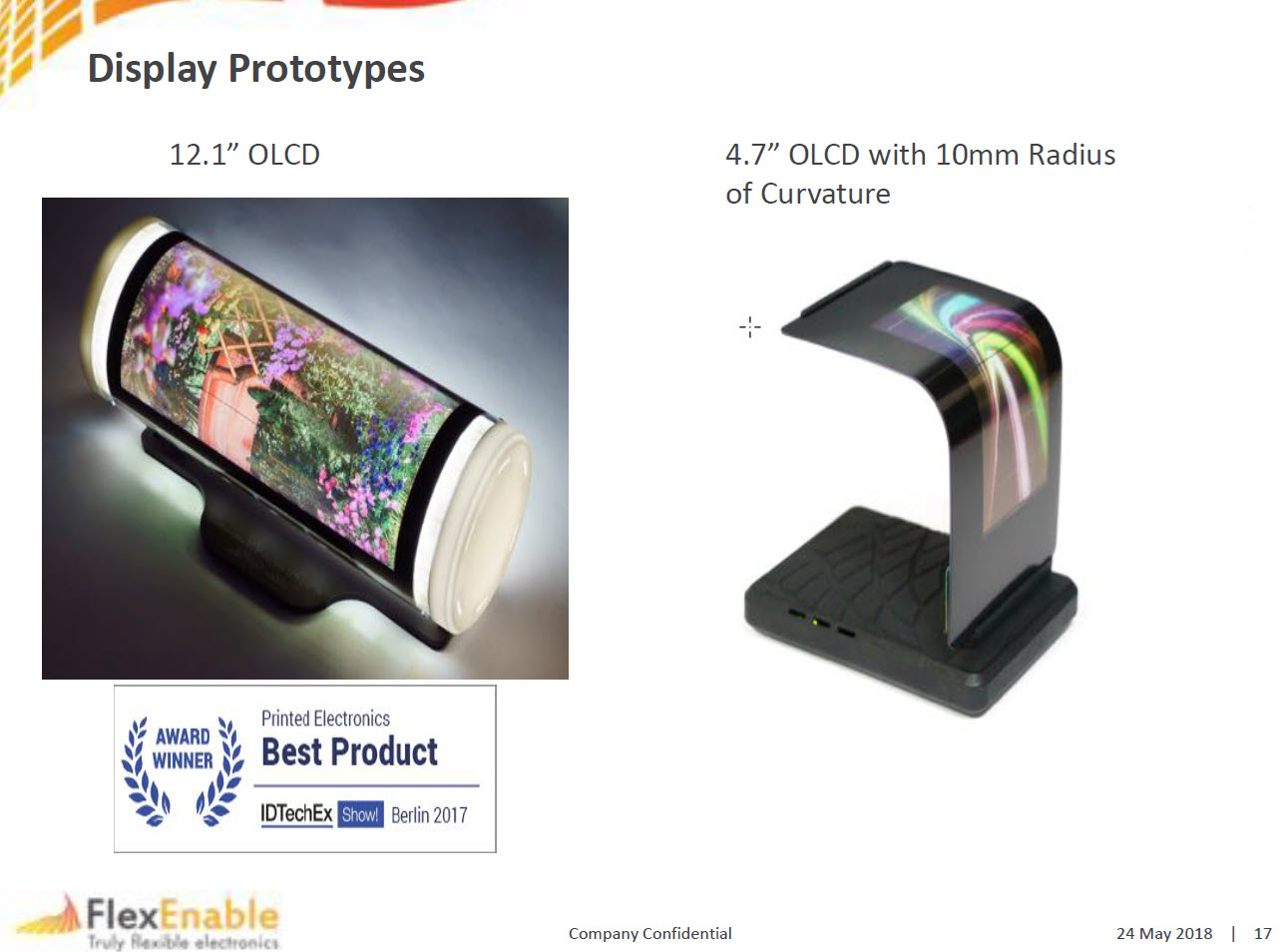

Mobility of the transistors continues to improve and is even good enough for OLEDs as well as LCDs and EPDs. Going forward, the company plans to integrate gate drivers and improving the quality of Organic LCD (OLCD) to compete with flexible OLED. The company is also developing mask-less production technology that could enable roll to roll manufacturing, Milligan believes.

The company knows how to make even large displays that are flexible, using LCD technology. At the show, the firm was showing the flexible displays (which we previously reported from MWC MWC 2018 Roundup Part 1). The company can make borderless LCDs and can wrap drive electronics under tablets, like you do with current smartphones. Automotive is also a big potential area and displays are likely to get into steering wheels and are also looking to replace side mirrors. Flexenable recently got investment from Novares, in France, which is developing automotive solutions. (Novares Invests in FlexEnable….)

As well as displays, the company is developing flexible X-Ray detectors, optical fingerprints (under display) and vein sensors. The technology is very thin (down to 40 um substrates). 3D sensing is under development and there will be a lot of applications for biosensors. There are no toxic materials and even stretchable materials can be developed, Milligan said.

The company will have revenues of around $4.5 million this year, but with the Truly business, the company expects to be profitable by 2020. The company is raising $12 million to $18 million in Series A funding at the moment, after getting an investment of $6 million from Novares.