Dai Nippon Printing (DNP) has significantly increased the production capabilities at its Mihara facility in Hiroshima, by integrating an additional wide-range coating device. This latest manufacturing equipment can accommodate a width of 2,500 mm, enhancing the plant’s overall output capacity by over 15%.

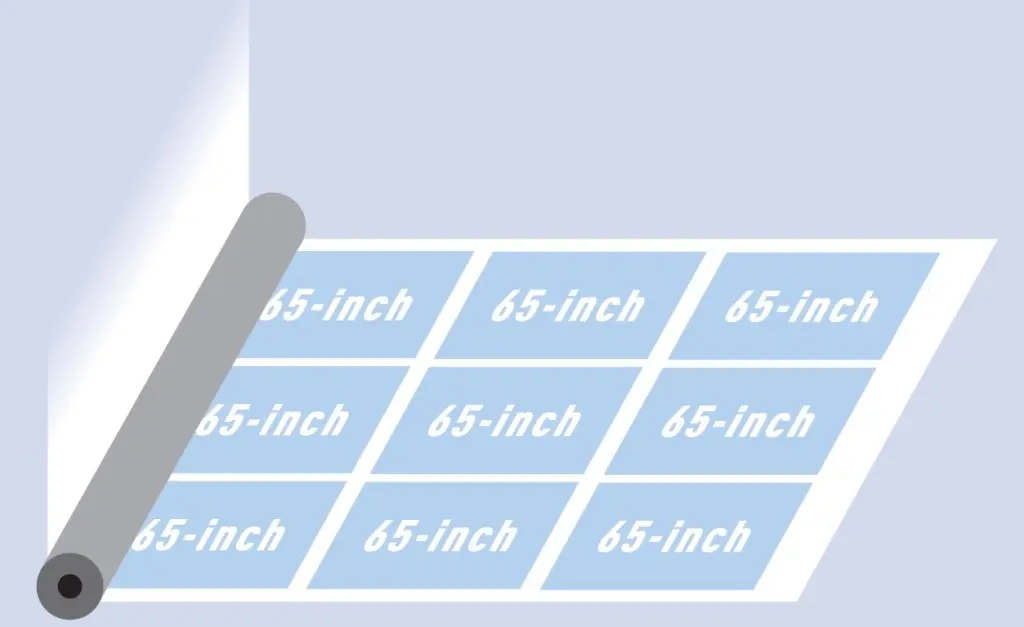

The addition of the new coating device is an attempt to meet the demand for larger TV displays. The wider 2,500 mm film accommodates 65-inch screens of 1436.4 mm x 809.0 mm, and improves the efficiency of film production for these large-screen devices.

This strategic investment is DNP’s response to the growing trend towards larger TVs, and the rise in demand for panels and polarizing plates,. Omdia has predicted that the combined area of TV and PC monitors is projected to grow at a compound annual growth rate (CAGR) of 5% from 2022 to 2026, and 4% from 2022 to 2029. The report also suggests that 65-inch TVs are becoming increasingly mainstream, leading panel and polarizing plate manufacturers in China to ramp up their production lines to match this trend.

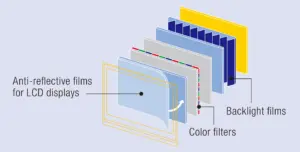

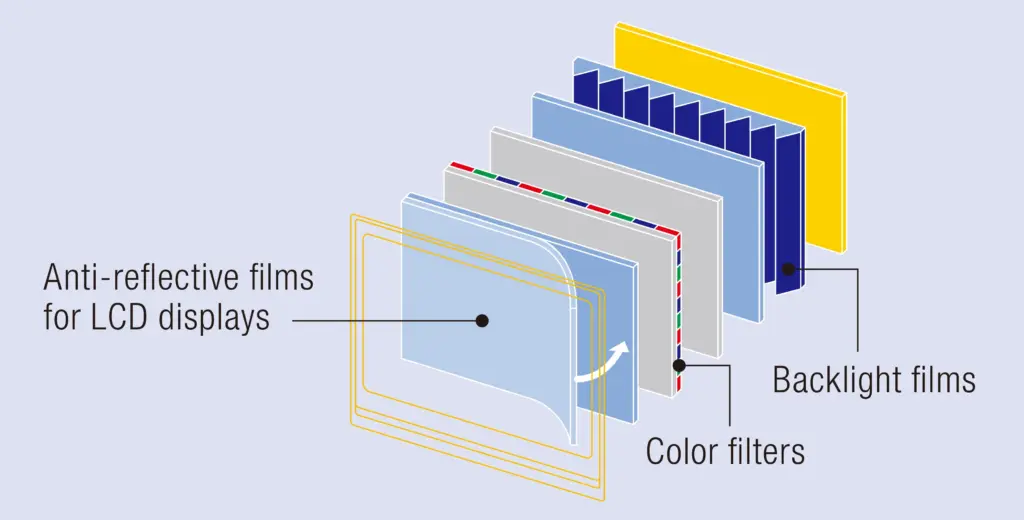

DNP first pioneered the introduction of a 2,500 mm wide coating device in 2018, The newly introduced equipment at the Mihara plant also has the capability to simultaneously coat two layers. As the need for sophisticated multi-layered coatings grows with display advancements, DNP’s looking to take advantage of the demand for anti-glare-low reflection (AG-LR) film and low reflection (LR) film will prove crucial.