Display Daily contributor Pete Palomaki recently had fun tearing down a Vizio Quantum Dot-enhanced TV and published a YouTube video to show how the backlight worked and the effect of the Quantum Dots. He spotted some interesting things and that got me digging.

One of the intriguing points that he spotted was that when he added back the brightness enhancement films (BEFs), the spectrum of the light being output changed in RGB balance. Given that BEF is normally intended to be neutral in their effect on the chromaticity of the light being output, it got me intrigued. It also made me realise that although BEFs are significant components in LCD displays, we haven’t often written about them on Display Daily.

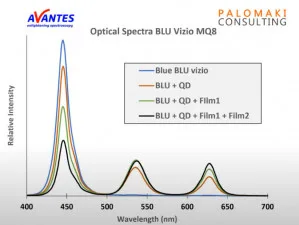

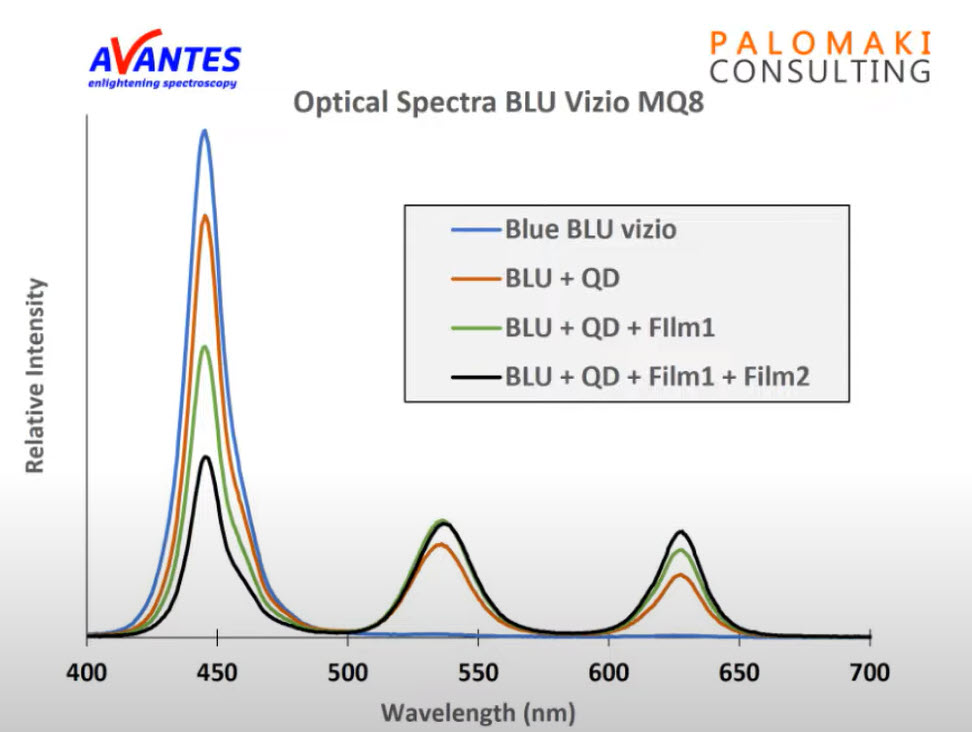

Note how the green and red components increase as more films are put back in the backlightFor those that are new to LCD or displays, the BEF is an important component. As everyone that works with LCDs knows, they work by exploiting the polarisation of light. Light enters the LCD in one polarisation and emerges through another polariser. The LCD works by controlling the degree of polarisation of the light going through. However, in general, the LEDs that are in the backlights of LCDs do not produce light with a particular polarisation and much of the light comes out of the LED at angles that are not optimal (although there will often be some work within the LED to try to direct the light).

Note how the green and red components increase as more films are put back in the backlightFor those that are new to LCD or displays, the BEF is an important component. As everyone that works with LCDs knows, they work by exploiting the polarisation of light. Light enters the LCD in one polarisation and emerges through another polariser. The LCD works by controlling the degree of polarisation of the light going through. However, in general, the LEDs that are in the backlights of LCDs do not produce light with a particular polarisation and much of the light comes out of the LED at angles that are not optimal (although there will often be some work within the LED to try to direct the light).

Light comes from the LEDs, goes through lenses and diffusers and is reflected from the back of the backlight, so if not processed, when it meets the entry polariser, the light that is not polarised the right way to go would be wasted. LCDs typically use a reflective polariser film that will bounce the light that is not correctly polarised back into the backlight unit. (BLU).

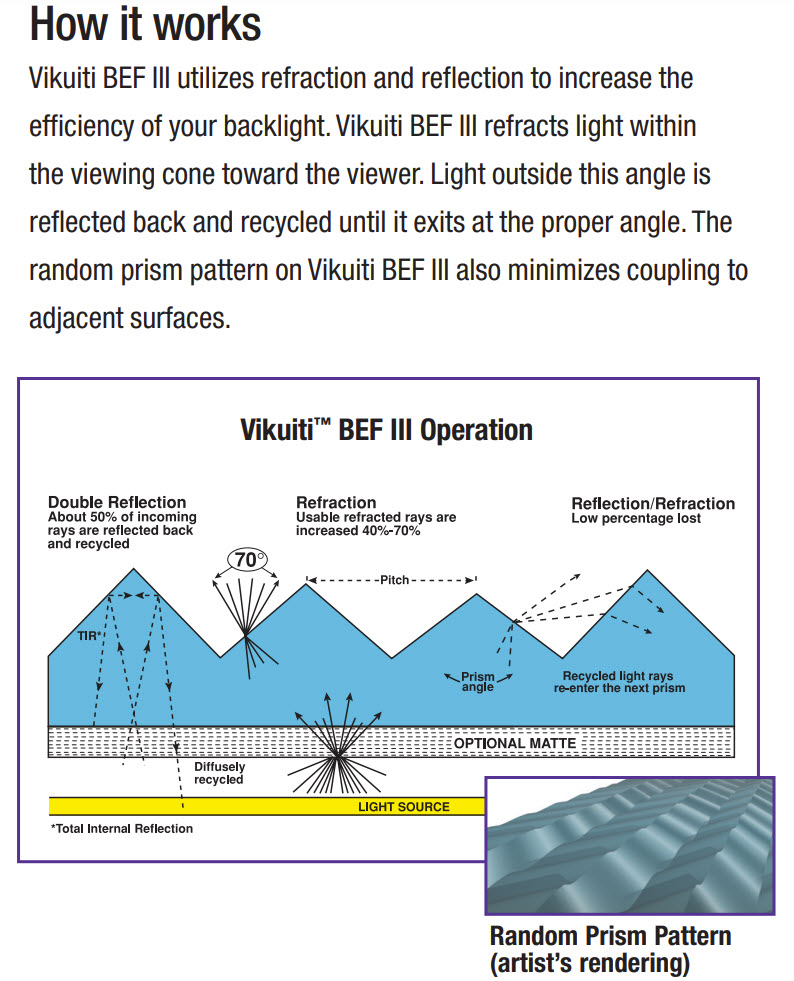

Light arriving at the wrong angle can also be wasted. BEFs typically have ‘microprism’ surfaces that help to both direct the light towards the polariser at the optimum angle and reflect back the light that is at the wrong angle back into the BLU. The surface has to be carefully designed to avoid moiré or other patterning effect.

Vikuiti Film from 3M – a major display film supplier

Vikuiti Film from 3M – a major display film supplier

Combining the reflective polariser and the light direction management into a single film creates a Dual BEF or DBEF.

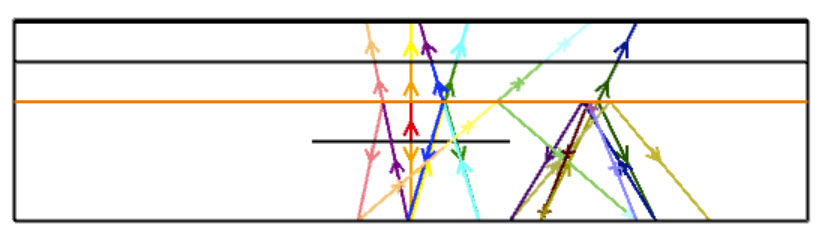

So the key point here is that the light doesn’t simply come out of the backlight and enter the LCD – much of the light is reflected multiple times until it is at the right angle and polarisation to exit the backlight into the back of the LCD.

This is from the modelling of a BEF system found here.

This is from the modelling of a BEF system found here.

So What Does This Mean for QDs?

This is significant when you have a QD film in the optical stack of films. Some of the blue light from the LEDs will simply go through the QD film, through the polariser and out through the LCD. However, much of it will be reflected back into the QD film again and some more of the blue light will be converted to red and green. Of course, when any remaining blue light reflects off the back of the BLU, the same process re-occurs.

There is another effect going on, as well. QD films work by converting light from a higher energy state to a lower state. That’s why they can convert blue to green or red, but not the other way around. However, green light has a higher energy than red, so as the green light goes through the QD film, some of that is also converted to red. The result is that the more effective the BEF/DBEF system is in reflecting light, the more red the spectrum will become. The optical calculations are made more complex because the photons emitted by the QD can come out in any direction.

Nanosys Confirms the Practicalities

I reached out to Nanosys, which is the leader in supplying QDs for TV films. The firm confirmed that this is what is happening and said that in its modelling,

“most of the blue photons have 1 to 3 passes”.

The effect of this multi-pass process through the QD film is to reduce the amount of QD material that you need as the more times it goes through the film, the more chance that a blue photon will be converted. Further it means that ‘a lot’ less red conversion material is needed than green, Nanosys said. Reducing the quantity is good because it is not cheap material. The firm also pointed out that changing from edge-lit systems to FALD and miniLED backlights change the optics a lot – after all, the LEDs do not reflect the light themselves, but tend to absorb it, so a lot of LEDs on the back can reduce the level of light that can be reflected.

(Just as an aside, I remember talking to Philips about its ColorSpark system which used a rod with embedded phosphors to convert blue LED light to green in LED projectors. The firm said that one of the special points of this design was its ability to avoid green photons being re-absorbed within the device after conversion from blue.)

Nanosys has modeling tools that it can use to help clients to optimise the optics in backlights using QDs. BEFs are more important if you have, for example, an edge lit backlight system with a wedge shaped lightguide plate (LGP) which is likely to have pretty uncontrolled light emission in terms of direction than in FALD or miniLED backlights. (BR)