Apple launched its Pro Display XDR in June 2019 (Apple Pro Display XDR has 6K and HDR) and drew quite a few comments for the price of its stand ($999!), but there was relatively little discussion of the details of the miniLED backlight, although we did find out that the LEDs were from Nichia and the backlight was from Radiant. But now we know more.

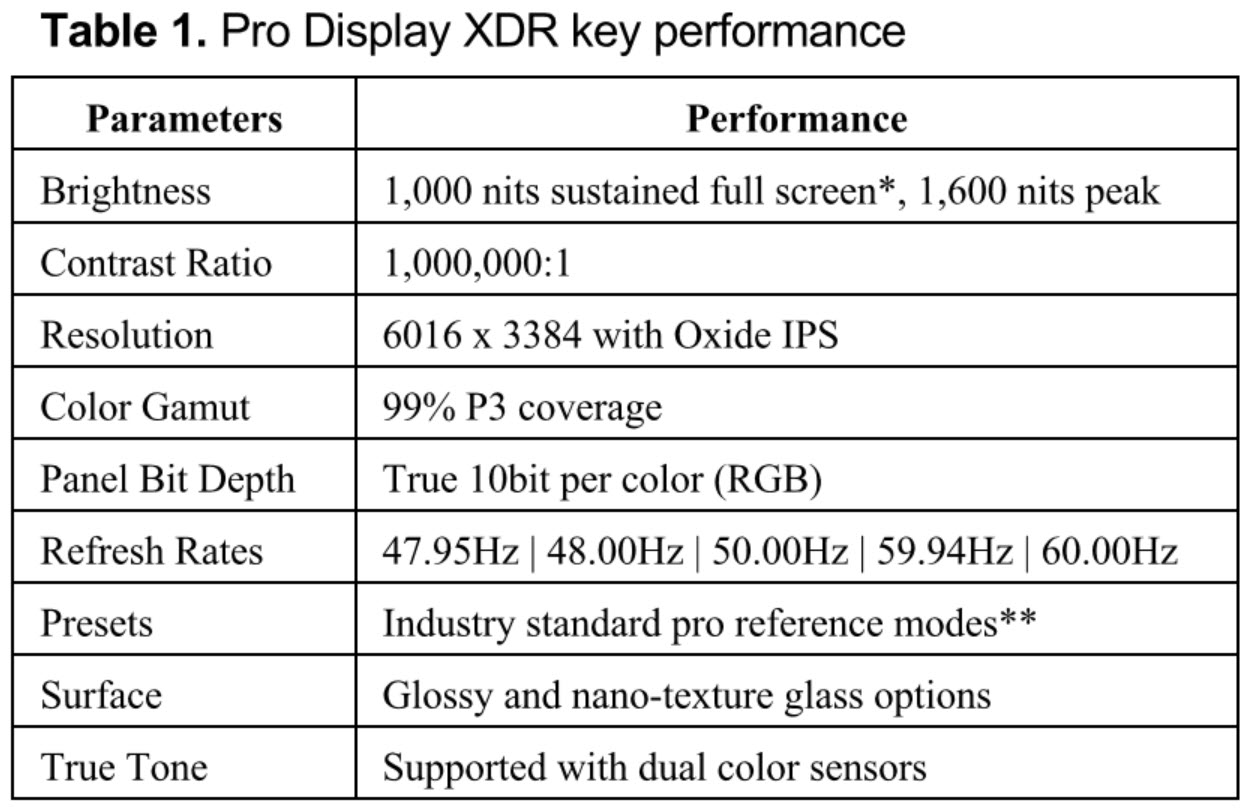

At Display Week this summer, Apple gave an invited paper on the display (although at the time of writing it is not or no longer available with the other papers on the SID/Wiley website and it was not included with press materials sent out earlier). Fortunately, I was able to dig out a copy, but not before the presentation itself had disappeared from the conference website. The monitor has a very high specification (below) and manages to combine high resolution with high brightness and contrast.

Now, the idea of miniLED is relatively simple. It’s an extreme version of the kind of full-addressed local dimming (FALD) that has been used in high end LCD TVs for years. However, such high resolution (20 million pixels – so more than double that of the 8 million of UltraHD/4K) is difficult to combine with high brightness in a smaller monitor (it’s a 32″). That’s because the combination means a small aperture ratio, with a lot of the light blocked by the structures of the display. It’s about 216 pixels per inch, much more dense than is usual on mainstream desktop monitors. A striking feature of the monitor is the case design which is clearly intended to cool the display very thoroughly. Apple has 576 LEDs in the backlight, each of which is individually controlled as a backlight zone.

The Optics

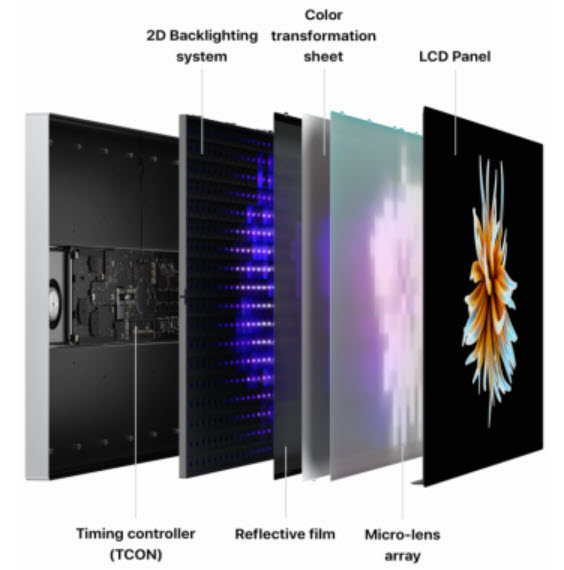

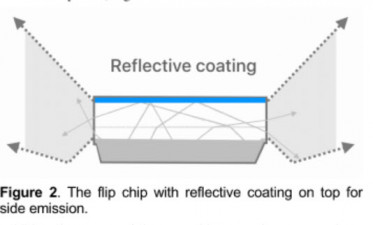

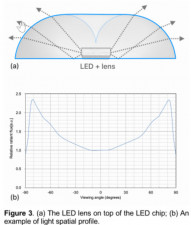

Even with this number of zones, there are only 32 zones across and 18 down. That means that each is around 22mm apart, or 188 pixels wide and high. Taking devices such as LEDs which have ‘point sources’ and homogenising the light to avoid significant brightness non-uniformity would be hard enough if you had plenty of room for lenses and other optics between the back of the backlight and the LCD cell. To do it in a very small space to keep the monitor slim has been a challenge. Apple uses blue LEDs and so a colour conversion film also had to be accommodated. Blue LEDs are more of a point source than white LEDs which have a bigger surface area and that allows more precise control of the optics. Using only blue light with a relatively narrow bandwidth also means optics can be simpler.

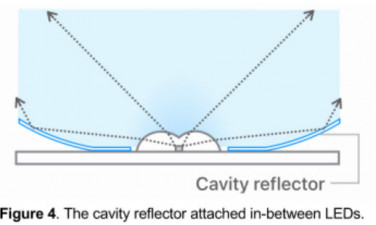

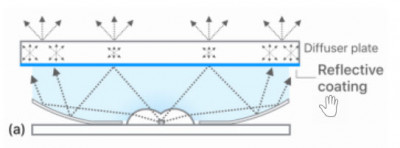

The flip chip LEDs use a reflector on the top surface to force the light out through the sides of the chip, which helps to start the distribution of the light. On top of the chip a ‘mushroom type dome lens’ was used to further bend the light down for mixing. That creates a ‘bat wing’ profile of light, brighter near the edges, but dimmer in the centre and at the extreme edges. Each LED with lens is then set in a ‘cavity reflector’ to direct the light up towards the LCD cell. Finally a diffuser plate further improves the uniformity.

Moving the diffuser away from the reflector improves the mixing, but allows more leakage of the light from zone to zone. To allow a thinner gap to limit the leakage, a special reflective coating is on the base of the diffuser that reflects back 80% of the on-axis light into the shaped reflector below. This is a point where the use of blue light makes the optics simpler.

The colour conversion sheet is based on red and green phosphors (not identified, and Apple doesn’t explain in the paper why it chose phosphors rather than, for example, quantum dots). However, more of the blue light going through the film at a diagonal gets converted to red and green, than the light going straight through. To avoid this ‘yellow shift’, another multilayer optical film was used on the base of the diffuser.

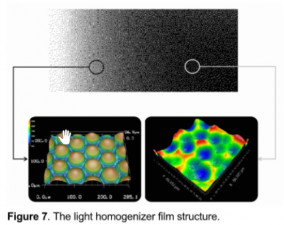

Finally, the light is still not as uniform as would be desired, so a microlens-based homogeniser film is used. That film is graduated from the centre of the display to the edge, with an optimised structure to compensate for brightness and colour differences.

So the optical stack of the backlight alone is LED > Reflection > Lens > Reflector > Coating > Diffuser > Film > Color conversion > homogeniser. Hmmm, you can start to see why this isn’t the cheapest display in the market!

Driving the LEDs

So, the optical path is very sophisticated, but what about driving the LEDs? That has always been a challenge as LEDs can vary a lot within a batch. To solve the variability issue, Apple developed its own LED controller and also uses an Apple proprietary custom camera (with 20 stops of dynamic range!) that can measure the point spread function (PSF) of each LED and store it in memory to allow compensation for the PSF of each individual LED to achieve a balanced result and minimise halo effects.

The control of the LED is much faster (>15X) than the LCD cell to allow the suppression of flicker by managing the output of the LED to match the slower response of the LCD itself.

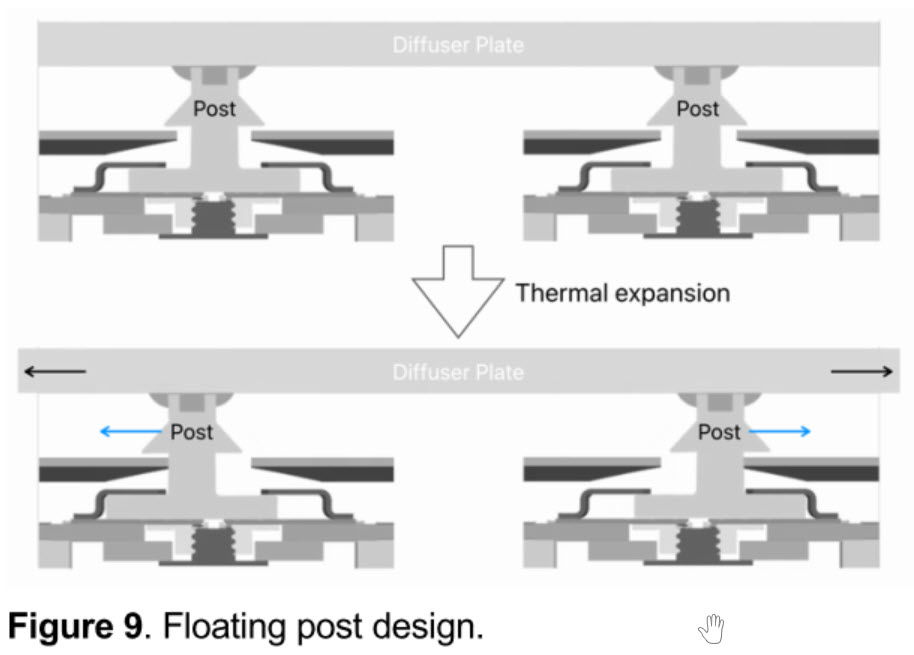

This Backlight is Hot Stuff

Finally, all these LEDs at such high brightness can produce a lot of heat, and all that heat is going to have an effect because of thermal expansion. On the other hand, the images could be dim and quite low levels of heat. When the air gap between the LED and diffuser plate is so critical, the expansion from light to dark needs to be managed very carefully. The XDR display has 44 special posts between the LEDs and the diffuser plate. These have to be carefully designed to allow some side to side movement, without blocking too much light through the panel.

So, there are some good reasons why this highly engineered monitor costs a bit more than others and the paper gives more understanding of the decision by the SID to include the monitor in its Display of the Year Awards.

I was a little disappointed that Apple didn’t give more information about the matte display coating option in the paper, but I’ll have a dig around to see if I can find out about that! (BR)