The award was granted because Eizo has introduced monitors with integrated calibration sensors for content creation. That’s not a new idea, Eizo itself introduced monitors with integrated calibrators in the medical market back in 2005 and companies including Barco have this kind of system in their medical monitors. Eizo introduced its first ColorEdge (for content creation) monitor with an integrated sensor in 2010. However, Eizo has clearly impressed studios and the press release about the award had a lot of positive comments from some impressive customers! (Staff at the company love that they are finally allowed to mention those that are in the release, having been sworn to secrecy for a long time).

Delivering an extremely consistent and high quality image is a multi-stage process. First, the monitor has to have the right hardware and the firm has been developing custom silicon for a long time to optimise performance. All monitors can be calibrated by using software, but there are inevitably compromises in this process. Calibrating using internal hardware is the best way to get an optimum image and the best components and panels also have to be used.

Individual Calibration

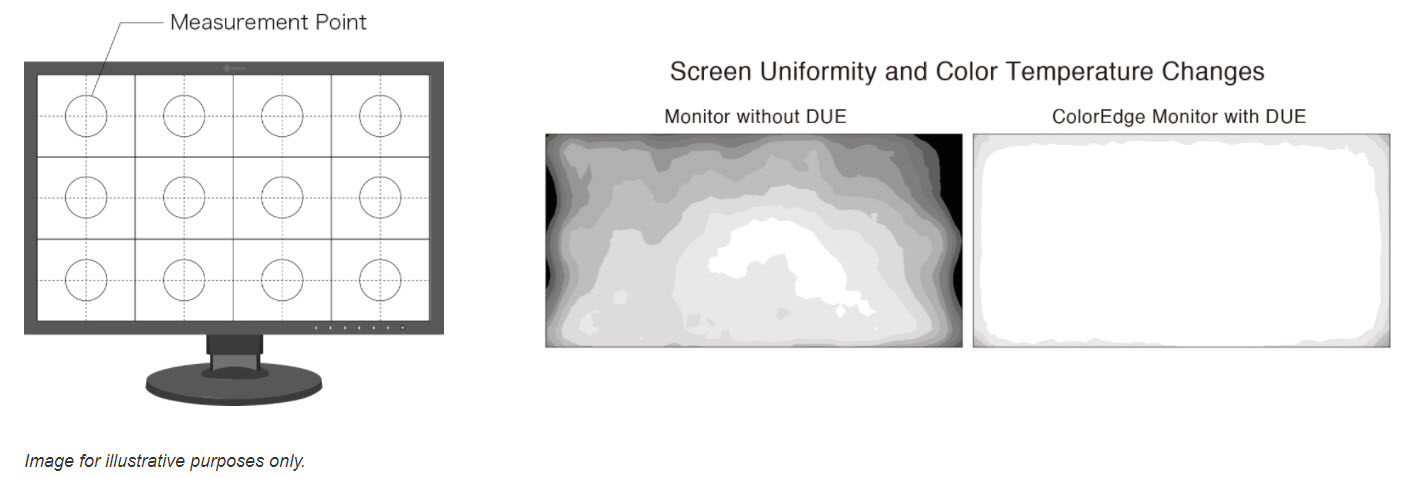

At the assembly stage, the Eizo monitors are initially individually calibrated for uniformity and colour accuracy. Each panel is measured and when repairs are made to monitors (unlike commercial grade monitors, there is a lot of expensive electronics in the monitor, so panel replacements are worth doing), replacement panels are ordered by repair facilities along with the data describing the uniformity of the particular panel.

The data is used with the firm’s own digital uniformity equaliser (DUE) to compensate for any non-uniformity. It is also possible for an Eizo facility to re-calibrate monitors that might need uniformity correction during their lifetime, although this is rarely needed.

Eizo’s Patented DUE Technology. Image:Eizo

Eizo’s Patented DUE Technology. Image:Eizo

The colour measurements are made at the factory with high end instruments and that allows an offset between the external measurement and the internal sensor to be calculated. I was surprised to see that the automatic sensors are actually Eizo’s own. It used to use externally-sourced sensors, but wanted better performance and so switched the type of filter in the sensor from gel to glass to give better results. (It uses two different classes of sensor at different price points and the better ones use glass).

The calibration sensor is under motor control and drops down to measure the colours. Image:Eizo

The calibration sensor is under motor control and drops down to measure the colours. Image:Eizo

Some content creators prefer using particular measurement systems for calibration, and Eizo can map the results from internal sensors to those external sensors to keep things consistent with clients’ internal preferences. Once the system set up, having the sensors integrated means that measurement and control can be done centrally, using software that Eizo has developed over many years to allow the collection of data about usage, performance etc. An ‘agent’ app runs on the host PC/Mac and collects data from the monitor, or issues commands, and communicates with the cloud.

This is built around an Azure-based cloud architecture that Eizo manages. Where security concerns do not allow connection to the cloud (I know of companies that will not allow any network connections on systems used for content because of the risks of piracy!), Eizo can supply on-premises server software, but that imposes a load in terms of system management/back up etc that can make the cloud more attractive to most.

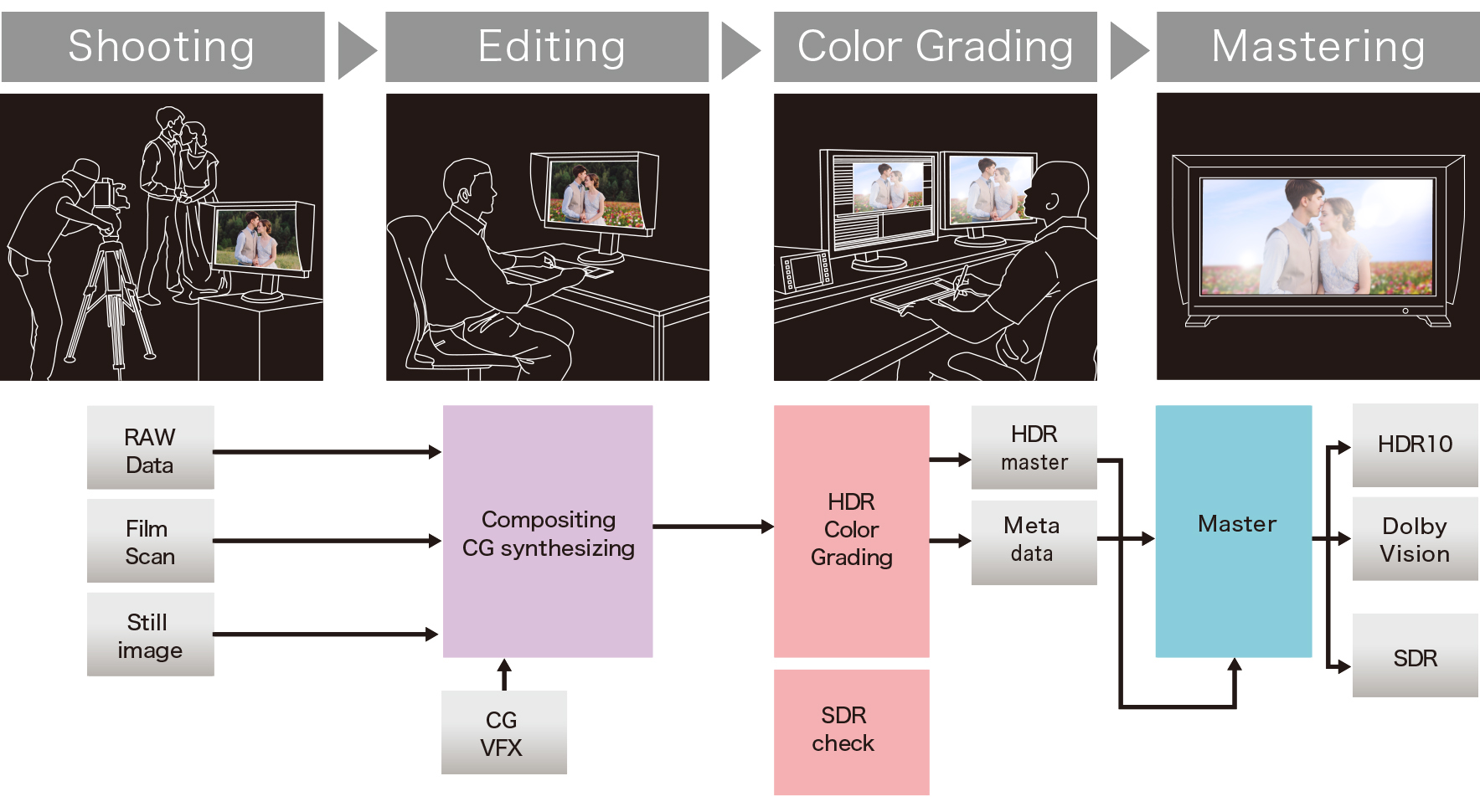

Image:Eizo – click for higher resolution

Image:Eizo – click for higher resolution

Of course, using the cloud-based architecture can ensure consistency of performance across the multiple stages that content will go through from capture to final rendering. In medical applications, this kind of control, with audit trails, is mandatory. After all, in radiography, accuracy is literally a matter of life and death. But it’s also important in creation. If image data is lost in the process because of bad calibration, it may not be able to recover it after processing.

You can see more about Eizo’s process and technology on its website.

Dual Panel Displays

I have a soft spot for the Eizo Prominence CG3146 monitor (which won the 2020 Hollywood Professional Association (HPA) Award for Engineering Excellence), which uses a dual panel LCD to give phenomenal brightness and colour volume. The main reason is that at IBC a couple of years ago, the demonstration of the monitor was the first time that, side by side, the LCD looked better than an OLED – and no ‘ordinary’ OLED, but a Sony broadcast monitor. After many years, that was the first time that I hadn’t preferred the OLED, so the demo made quite an impression. (at low luminance, they panels looked pretty well the same, but at higher brightness, the LCD looked much better) Since then, there has been more activity with dual panels in the professional field, with Sony telling us at IBC a couple of years ago that it had stopped development of OLED-based broadcast monitors in favour of dual cell LCDs.

Now a year or two ago, there was a fair amount of buzz around the concept of dual cell LCDs for TV applications. Hisense and TCL showed good looking prototypes and sets were launched in some markets, I believe. There was a lot of interest in automotive, in particular, and we reported on the development of dual cell LCDs by Visteon. We also reported on developments by Flexenable, which has Novares (a significant automotive supplier) as an investor. However, the high end dual cell that is used in broadcasting is currently made by Panasonic and that company has said that it will get out of the LCD business. There was, as far as I could tell, no activity in dual cell TVs at this year’s CES (with miniLED taking the headlines for LCD), so the interest in dual cell TV seems to have died.

Staff at Eizo are not commenting on future supplies of dual cell LCDs, but I would speculate that may make sense for a panel maker that likes to include high margin lower volume products in its range to buy the technology from Panasonic to continue the business. (BR)

Note: The original version of this article referenced an ‘Oscar’ for Eizo, but a reader pointed out that it was a Science & Technical Award. That was my mistake – I didn’t understand the different levels of award when I wrote the piece, so I have corrected it. (BR)