A research team led by Kyung Cheol Choi at the Electric and Electronic Engineering Department within the Korea Advanced Institute of Science and Technology (Daejeon, Korea) is developing an OLED technology that is hoped to enable display devices suitable for integration into clothing.

A recent article on this subject by the team is entitled “Highly Flexible and Efficient Fabric-Based Organic Light-Emitting Devices for Clothing-Shaped Wearable Displays.” It was published in Scientific Reports 7, Article number: 6424(2017). A copy of the article is available on-line and can be found here.

There are three principle approaches to producing displays that are suitable for use in clothing.

- The display can be attached to the clothing. This is the simplest method but typically reduces fabric flexibility. The main reason for this is that the kinds of plastic substrates used to fabricate flexible displays are not as pliable as fabrics.

- Fabricate a light emitting fiber. Results to date show good display related properties for such fibers but their integration with fiber-based transistors has not been perfected.

- The direct fabrication of a light emitting device on a fabric. This method offers real potential because the components in the display device should be as flexible as the clothing fabric itself since it would be not be made of plastic but, rather, actual fabric.

It is this last approach that was investigated by the team. The challenge addressed by the team is that previous efforts along these lines have produced devices with low luminance and low efficiency. In addition, it was found difficult to maintain device performance when the clothing containing the integrated display was exposed to significant mechanical stress.

To address these issues, the team investigated two different approaches that they called fabric-type and fiber-type. The article published by the team contains a great deal of detailed, technical information on the creation of the fabric, the methods and results of testing and on the performance specifications of the display device. Here are a few, top level comments.

A conventional fabric surface is physically rough having hundreds of micron sized bumps. Such a rough surface is not suitable for the fabrication of 200 nano meter thick OLEDs since a surface roughness of a few nm is needed to prevent leakage current and electrical shorting. Therefore, the fabric substrate in this work was woven tightly with fine thread to reduce the surface roughness. In addition, a roll-to-roll, thermal lamination-based planarization process was applied to the fabric to form a flat surface.

The OLEDs were designed as a “top-emitting, micro-cavity structure to improve the external quantum efficiency with a host-guest energy transfer system to increase the internal quantum efficiency. A highly reflective Al cathode and a semi-transparent Ag anode generated strong micro-cavity effects, and the resonance wavelength was matched with the electroluminescent peak of an emitter.”

OLEDs are extremely sensitive to water vapor and oxygen. To operate OLEDs for an extended period of time, a moisture and oxygen barrier is necessary. The proper name for the barrier is an encapsulation. The encapsulation needed for fabric-based OLEDs has to be flexible so that the display device will perform normally even after the clothing is subjected to vigorous and repeated mechanical stresses. The encapsulation must also be transparent to allow the light emitted by the OLEDs to transmit outside the fabric. The team determined that the solution that best meets these requirements was a multi-barrier encapsulation composed of alternative moisture barriers and spacers. The multi-barrier encapsulation in this work was composed of dense Al2O3 layers and soft silane-based polymer layers.

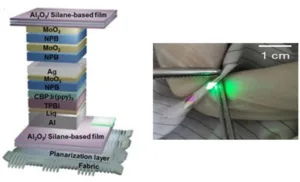

The left hand portion in the figure below illustrates the structure of the encapsulated fiber-based OLED. The right hand portion of the figure illustrates an emitting fiber.

Left: Schematic illustration of the fabric-based, encapsulated OLED. Right: OLED implemented through fabric

The mechanical flexibility of the fabric-based OLEDs was evaluated by cyclical bending tests. It was determined that the fabric-based OLEDs that had empty space within the fabric, movable fibers and a wavy structure showed better strength characteristics, such as higher flexibility and lower stress.

The electrical and optical performance capabilities of the fabric-based OLEDs were determined to be sufficient use both as an indoor and an outdoor display.

To measure the luminance variations over time, devices were placed in a constant humidity, constant temperature chamber at 30 °C and 90% relative humidity. The luminance and the current efficiency was found to decrease gradually over time.

In summary, the team demonstrated a highly efficient and flexible light emitting fabric for clothing type wearable displays. -Arthur Berman

Korea Advanced Institute of Science and Technology, Choi Kyung-chul, +82-42-350-3482, [email protected]