A team of researchers headed by Masayoshi Higuchi of the Electronic Functional Macromolecules Group at the Research Center for Functional Materials within the National Institute for Materials Science (Tsukuba, Japan) are developing a flexible display that can be cut into a desired shape with a simple pair of scissors.

Conventional displays, such as LCDs and OLEDs, are difficult to cut once they have completed their manufacturing processes. This is true even if the display’s substrates are made of a flexible material. One of the several reasons for this difficulty is that the electro-optical material within these displays is sensitive to contamination by both moisture and oxygen. As a result, during or soon after the cutting process, it is necessary that the exposed edges be sealed preventing exposure to the environment. The new display technology directly addresses this issue.

The new display is made from an organic/metal hybrid polymer having electrochromic properties. Materials of this type are composed of “supramolecules formed by complexation of metal ions and organic ligands.” The electro-optical properties exhibited by such materials are due to metal-ligand or metal-metal interactions.

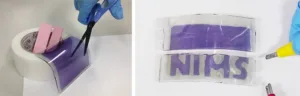

The organic/metal hybrid polymer material can be sprayed onto a flexible substrate. The breakthrough is that the layer thus formed is stable with respect to moisture and oxygen. Thus, the substrates can be cut with a scissor without the need to seal the edges.

Another feature of the new display is that it needs to be powered for only a few seconds to switch visual information. In addition, the image presented on the display will remain visible even after the power is discontinued.

It should be noted that, at this time, the new display is designed to present only one color and has a limited display area.

Although the material is still in an early stage of development, it is still possible to imagine possible applications. The researchers suggest that when displays based on this new material are able to meet commercial requirements, they will likely be used in applications that cannot be adequately served by conventional display technologies. The new display might, for example, be attached to surfaces that have a complex shape. Applications in this category might include smart wearables in which displays are integrated into clothing or into devices that conform to the shape of the user’s wrist. The new display might be attached to the surface of buildings. The researchers also envision using the conformable display material to change the colors of car interiors, sunglasses and windows.

It is the intention of the researchers that, in future studies, they will investigate means to make the material capable of displaying multiple colors and to increase the size of the display.

-Arthur Berman

National Institute for Materials Science, Masayoshi Higuchi, +81-29-860-4744, [email protected]