Display Materials, Components and Manufacturing – (This article is free for all to view) – Canatu (Helsinki, Finland) used the Printed Electronics USA conference to release it latest film, called CNB In-Mold.

This film, based on conductive carbon nanobud (CNB) technology, can be stretched and formed over raised or depressed surfaces to bring touch technology to places it could never be used before. Expect to see this applied to control buttons in automotive and white good products in about a year.

Just before the event, the company also announced that it has qualified TouchTurns (Santa Clara, CA) to begin to produce projected capacitive flat or flexible touch sensors using its CNB technology. The plant, located in China, will offer OEM customers access to the CNB-enabled touch sensors.

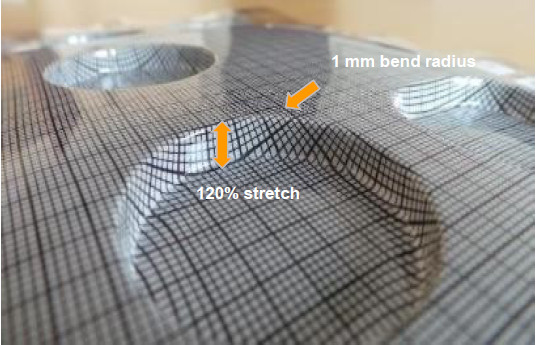

CNB In-Mold Film is stretchable up to and beyond 100% and can be easily formed and back-molded using standard industrial processes such as Film Insert Molding (FIM). This means that CNB touch sensors can be produced in almost any shape, from smooth spherical domes to sharp edged casings with recesses and bulges.

With CNB In-Mold-based touch sensors, mechanical buttons in automotive dashboards, portable and wearable devices, washing machines, clothes dryers, dishwashers, ovens and other appliances can be replaced with a robust water- and dust-proof 3D-formed touch user interface.

We had a chance to interview Dr. Erkki Soininen, vice president of marketing and sales at Canatu, about this latest development. We last spoke with him at the Display Week event last June, where the company collected “Best Component of the Year Silver” award from SID.

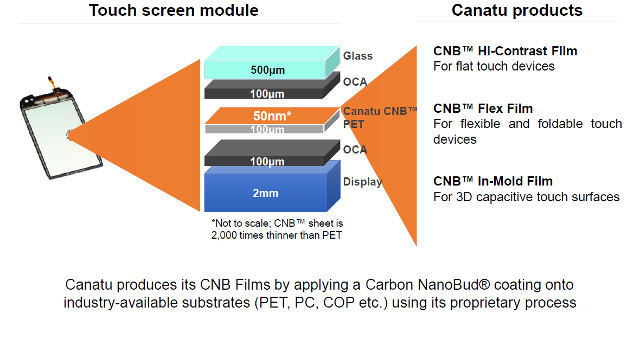

At that time, Canatu said it was working on about 30 projects and had released two films: the CNB Hi-Contrast film and the CNB Flex film. Now, it has added the CNB In-Mold film and the company is working on 40 projects.

Soininen explained in June that the company was just finishing up rigorous environmental tests on its first two films and expected to be in mass production by Q3’14. Both films passed all these tests and are now in mass production. Environmental testing on the In-Mold film should be done soon.

I asked for some more details on the projects that Canatu is working on and Soininen said that it now expects the first products to reach the market in Q1’15. These will be mobile devices like laptops, tablets and smartphones and they will use the CNB Hi-Contrast film. This is designed to create ultra-low reflectivity display surfaces with “zero” haze, improving contrast in bright ambient by as much as 40%. There are about 15 projects ongoing here.

In Q2’15 the first wearables should hit the market. There are five projects which will feature the CNB Flex film. By Q3’15, white goods using the In-Mold film should be ready. The company is working with three major appliance makers which combined own 50% of the market, is how Soininen characterized these customers. By Q4’15, automotive makers may be ready to introduce In-Mold based products. Canatu has 10 active projects here.

The CNB structure is different to what others are working on. It is based on carbon nanotubes, but a Fullerene is added to the structure. This apparently helps to create long strands that look like black spaghetti.

The CNB structure is different to what others are working on. It is based on carbon nanotubes, but a Fullerene is added to the structure. This apparently helps to create long strands that look like black spaghetti.

CNBs are manufactured in Finland on a roll-to-roll machine. As illustrated in the photo, a roll of un-coated substrate material is loaded in the glass encased section, which has a controlled micro-environment for cleanliness. This is then fed down the line. The nanobud reactor is the tall component above the middle of the line. This is a gas phase deposition onto the film as it rolls by the chamber. A second glass encased section at the end of the line rolls up the coated film. It is a very compact line and very environmentally friendly – no wet processing, just electricity is needed. It can even support in-situ patterning.

Canatu has done an excellent job of lining up its supply chain partners to enable product OEMs to use the film. It is one thing to have the technology and manufacturing capability to make the film, but to see it used in real products, required developing the relationships with the touch controller companies, touch module integrators and display companies, so a finished display can be purchased.

Canatu has done an excellent job of lining up its supply chain partners to enable product OEMs to use the film. It is one thing to have the technology and manufacturing capability to make the film, but to see it used in real products, required developing the relationships with the touch controller companies, touch module integrators and display companies, so a finished display can be purchased.

“Since SID, this is where we have focused our attention”, noted Soininen. “The SID award helped open doors and we worked with the finished product makers and the supply chain partners to help establish the ecosystem. It was very important to work at the OEM level to create some pull from them to the supply chain. We now have a very nice supply chain ecosystem that meets the needs of these OEMs”. – Chris Chinnock

Canatu , Erkki Soininen, +358-40-574-1504, [email protected]