Display Daily has reported on Crystalplex and their new quantum dot (QD) technology in the past, including “Crystalplex Gets Patent for Sapphire Quantum Dots” and “Crystalplex to Offer New Technology QDs.” (Subscription required for both.) On Oct. 25th , Matt Bootman, Chief Executive Officer and President of the company, gave a presentation on their technology for the Mid-Atlantic chapter of the SID that revealed new details on both their technology and their business plans. Ken Acer, Director of Business Development for the company also attended the meeting.

Mat Bootman, CEO of Crystalplex, at the October SID-MAC meeting

Mat Bootman, CEO of Crystalplex, at the October SID-MAC meeting

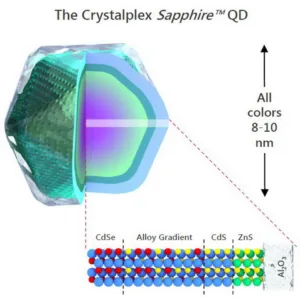

The company’s key technology is the gradient core quantum dot. With this technology, the wavelength emitted by the QD is controlled by the composition of the QD, not the diameter, as in other QD designs.

Crystalplex Cd-based QD

The “gradient” in gradient core is a gradient in composition from the center to the outer edge of the core. In their current products, the gradient core has CdSe at the center and CdS at the outer edge of the core. This gradient involves a single transition and three different atoms, Cd, Se and S. According to Bootman the company is developing a Cadmium-free version of their QD. He said this CD-free version involved four separate atoms and two transitions between the center of the core and the edge. He did not specify which four atoms were involved.

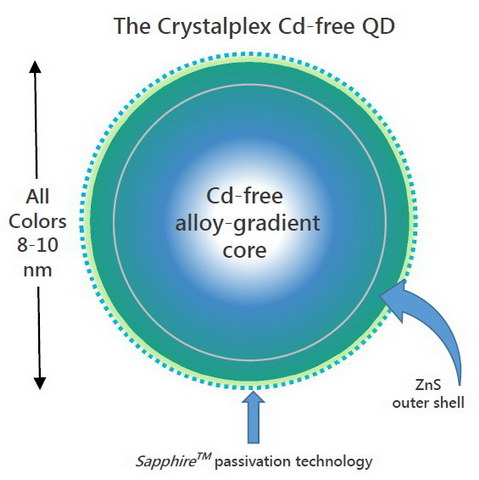

Like the Cd-based QD, the Cd-free QD then has a ZnS layer added to the outside and finally an Al2O3 layer to the outside of the QD. Al2O3 is the chemical formula for sapphire and the company has adopted the trademark Sapphire for their passivation technology.

According to Bootman, the entire process, including forming the core, adding the ZnS layer and then the aluminum for the sapphire layer takes place in a single batch reactor over a period of hours. In a Cd-based QD, the higher reactivity of the CdSe precursor compared to the CdS precursor results in a CdSe core as that material is formed first. As the CdSe precursor is depleted in the reactor, more CdS forms and by the time the QD has grown to full size, the outer layer is almost pure CdS. Note that this reaction is allowed to go to equilibrium – all the precursor materials are used so the reaction stops on its own. According to Bootman, in conventional, size-based QDs, the reaction must be quenched suddenly when the QDs reach the desired size. This quenching step adds significant problems to QD production and can lead to a variation in QD size, increasing the optical bandwidth.

The waste products from the growth of the core are purged from the reactor and then the ZnS layer is added. Finally, a layer of aluminum is added to the nearly-finished QD. Bootman says that this layer is about five atoms thick. When the QDs are removed from the reactor and the solvents used are removed, the outer Al layer reacts with the oxygen in the air to form a sapphire layer about five atoms thick. Sapphire is both very transparent and very resistant to penetration by oxygen and water so this five atom layer is the thickest that can be formed by oxidation of an aluminum layer. This layer then protects the ZnS and QD core from the oxygen in the air.

Schematic of a Crystalplex Cd-Free QD.

A similar process is used to make the Cd-free QDs. According to Bootman, work on Cd-free QDs is “an active research area” for the company. He said that Cd-free QDs, whether from Crystalplex or from a competitor, will have two problems. First, they will have a lower quantum efficiency than Cd-based QDs. Second, they will have a wider bandwidth, about 55nm full width at half maximum (FWHM) compared to about 30nn FWHM for Cd-based QDs. Both of these factors lead to lower efficiency for the Cd-free QDs in a display application.

The company is currently using batch process vessels 1 litre in size. Bootman said there was no problem expected in the use of 20 litre reactors when the time came to go into such large-scale production that 1L reactors were no longer sufficient.

He added that due to a particularly bad experience with cadmium in the last century, Japan has an especially strong aversion to Cd in consumer products, solders, etc. where, if you ignore its toxicity, Cd is the logical choice. In Europe, RoHS currently allows an exemption for Cd-based QDs but he was not certain how long that would last.

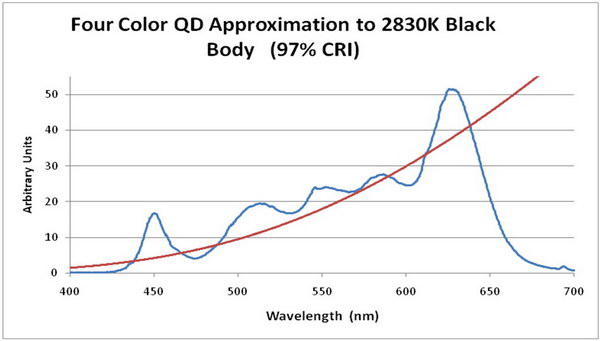

Spectrum of a white LED using four types of Crystalplex CDs

Spectrum of a white LED using four types of Crystalplex CDs

Besides displays, Bootman said he see a good future for Crystalplex QDs in general lighting applications. Of course, in general lighting, the wider bandwidth of Cd-free QDs would actually be an advantage and lead to a higher color rendering index (CRI) for the light produced. He said that with a 450nm blue LED and a mixture of four different QDs, a light source with a CRI of 97% could be produced. He added that since little or not infrared light was produced by the QD solution compared to the phosphor solution, the overall visible throughput was higher.

Absorption and emission spectra for four different Crystalplex QDs. Bootman said the QD center wavelength could be made accurate to ±2nm.

Absorption and emission spectra for four different Crystalplex QDs. Bootman said the QD center wavelength could be made accurate to ±2nm.

In addition to the QD itself, Crystalplex has done significant research and has patents on the polymer technology needed to disperse the QDs so they can be used in a wide variety of display and lighting applications. They have developed the materials and processes needed to produce solvent cast films, extruded films, sheets, rods, etc. and injection molded parts. Their work has involved both organic polymers and silicone materials. They have also developed QD inks that can be ink jet printed with an accuracy needed for the red, green and blue sub-pixels of LCD displays.

When asked about the company’s business plans, Bootman did express a willingness to license the IP for the polymer and silicone processing for applications. He said they intend to produce the gradient core QDs themselves and not license the process. He added that there was more than just the patent IP needed to make the QDs, there was a lot of proprietary know-how as well. He added that if someone wanted to make these QDs and get the needed technology and know-how, they’d have to buy all of Crystalplex. He seemed quite open to a potential offer. –Matthew Brennesholtz