Crystalplex Corporation, a Pittsburgh, Pennsylvania company, was founded in 2004 as a biochemistry and diagnostics laboratory, specializing in nanotechnology for the life sciences industry. In 2009, the company directed its research to optoelectronics and developed high-performance nanocrystals for photoluminescent, electroluminescent and photovoltaic applications. As a result, Crystalplex has developed alloy gradient quantum dots (QDs) for the optoelectronics industry, including the display industry.

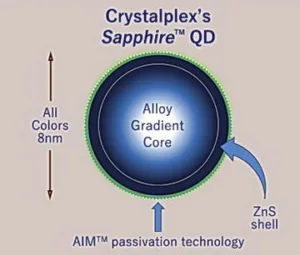

Anatomy of a Crystalplex Quantum Dot

In other commercially available QDs for the display industry, the wavelength of the QD is determined by the diameter. Not so for Crystalplex’s Sapphire QD, where all colors are the same diameter, about 8nm. (Note: Sapphire is a trademarked brand name, and does not describe the material in the QDs) The emission color of a QD is determined by the composition of the alloy gradient core.

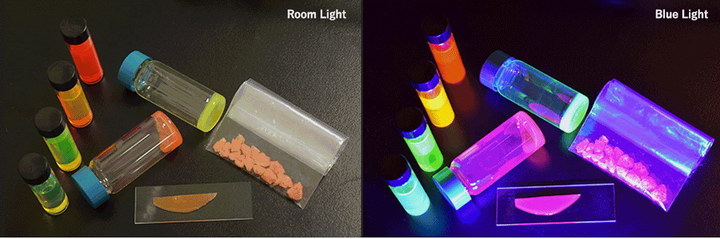

Crystalplex QDs illuminated by both room light and blue light, as in a display application.

Crystalplex QDs illuminated by both room light and blue light, as in a display application.

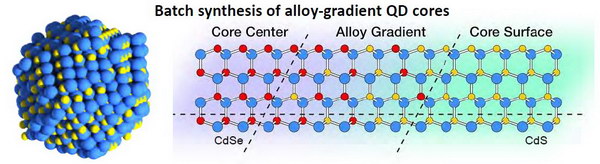

Dr. Lianhua Qu, Chief Technical Officer of Crystalplex, and three colleagues, one from Liquid Ion LLC and two from Crystalplex, presented a poster paper at the International Liquid Crystal Conference (ILCC), held July 31 – August 5, 2016 at Kent State University in Ohio. This paper describes both the manufacturing process and the optical properties of the current generation of cadmium-based QDs from Crystalplex.

The “alloy gradient” refers to the fact that the Crystalplex QDs are CdSe at their center and CdS at their surface, with a gradient between the two materials. According to the company, they are made “in a batch equilibrium process where reactants are mixed and then heated to initiate crystal growth. The higher reactivity of the Se precursor results in a Se – S gradient. This process enables precise emission tuning by varying QD composition instead of size. Synthesis of alloy-gradient QDs also eliminates crystal size uncertainty inherent in the rapid quenching process of size-dependent quantum dots, significantly simplifying manufacturing scale-up.”

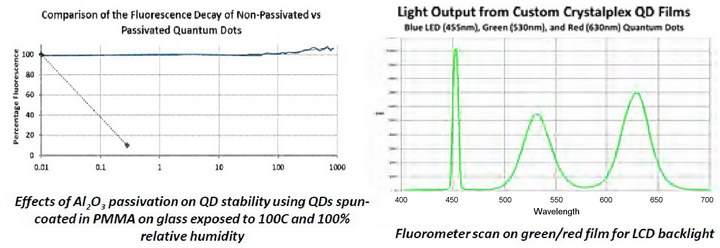

The QDs are then given a ZnS shell and are finally passivated using an Al2O3 layer, called by the company AIM, for “Advanced Isolation Mechanism.” Crystalplex has received a Notice of Allowance from the U.S. Patent and Trademark Office (USPTO) for this Sapphire shell technology applicable to both cadmium-containing and new cadmium-free QDs. Crystalplex also has an earlier issued patent, US 8,454,927, titled “Alloyed Semiconductor Nanocrystals.”

According to the company, this technology provides high stability, high quantum efficiency (>80% for all colors), narrow emission bandwidth (~30nm FWHM for all colors) and very low manufacturing cost.

The company says, “for utility in optoelectronics, QDs must be dispersed in a stabilizing matrix to maintain QD spatial separation. Crystalplex accomplishes this by using either A.) a polymer-QD composite system added as a QD polymer composite for solvent casting, as a QD concentrate for thermoplastic extrusion of acrylics (over 200C) or as a QD concentrate for thermoplastic injection molding, or B.) an inorganic QD composite system added to two-part silicone thermoset polymers or two-part acrylic thermoset polymers.”

The company also says it is working on silicone systems with embedded QDs for direct LED encapsulation in low temperature applications (below 85C) and silicone systems with embedded QDs as a printable ink.

Although the QDs described in the ILCC paper were cadmium-based, the company also says it has “Cd-free and RoHS compliant Cd options.” Details on the Cd-free QDs are not currently available. If they become available, a follow-up article will be written. –Matthew Brennesholtz