Flexible displays are one of the darlings when we think of future display technologies. Remember those high gloss images of devices with roll-up displays that will allows us to roll out a 12” screen from a pen? While we are still not there (even though I have seen pretty good prototypes already), this is actually a pretty simple implementation of a flexible display.

When we roll a display only in one direction all forces on the various layers act in one direction. This leads to material failures like cracks in these layers that will typically run perpendicular to the rolling direction. This failure mode leads to specific specifications such as bending radius and roll / unroll cycles. The smaller the bending radius, the closer I get to a display stored in a pen. The more often I can roll/unroll a display the closer I get to a commercially viable product.

Source: Pinterest.com

However, when we talk about a flexible display we often think about the electronic newspaper like the one Harry Potter used to read including video and running without battery power. Interestingly this is something e-paper solutions based on electrophoretic displays could almost accomplish. Not without power though. At one point LG showed a prototype based on a steel backplane. This is, by the way, one of the real issue with electrophoretic displays not being flexible, you need an active matrix backplane to create images. (although Canatu showed flexible E Ink displays at SID and Flexenable & Plastic Logic have both done a lot of work on – Man. Ed.)

The other option to create a flexible display is the OLED display on a flexible backplane. Samples of this technology has been shown for years and have made their way in many products. Today most ‘flexible display’ products are using the display flexibility to create a slightly curved product or bend the display around an edge. In most cases the final device is more or less rigid, even though the display itself is flexible. This means the display is being bent once during production and remains in this state for the rest of its life cycle. This is a far cry from the electronic newspaper paradigm.

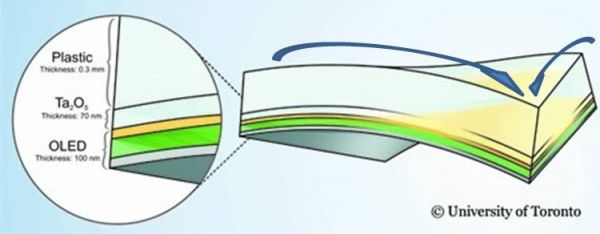

To make things even more complex look at the schematic drawing of a flexible displays shown by the University of Toronto. As you can see, once you bend the display simultaneously along two different axes, the forces implied on the display stack become quite complex. Besides the bending radius issue we now have to deal with compressive and tensile stresses depending on where we look. The arrows indicate that in this kind of distortion, you will have compressive forces in this corner, while there will be tensile forces acting along the edges of the display panel.

In addition, in the corner of a ‘3D round surface’ the material under compression will tend to buckle because it has nowhere to go. When we stamp metal parts this way it leads to a variation in material thickness, but this is a consequence that is not really acceptable for any electronic display. The material stack of an OLED display cannot change the layer thicknesses without rendering the device more or less useless.

In other words, a flexible newspaper may be possible one day, but try to wrap this display around a ball will not be possible. For this we will need stretchable displays. That’s something that even the leading edge companies are not really suggesting today.

So, when we are able to produce a flexible display in the near future we will be looking at the roll up or foldable display at best. This will lead to devices that offer a complete new form and ‘coolness factor’ for the consumer. At this point the consumer will not care what the definition of flexibility is. Let’s leave the stretchable display for the next generation of analysts to write about. – NH