DNP Denmark (Karlslunde, Denmark) recently launched a new rear projection (RP) screen, called the WVF, short for Wide View FEL Screen, that targets the rear projection cube market, especially for small and mid-sized installations. DNP Denmark is the worldwide large-screen centre of Dai Nippon Printing Co. Ltd (Tokyo, Japan). Søren Weis Lindegaard, Business Manager OEM, told me that the RP cube market is the last remaining significant market for RP screens. He said the market was stable at about 50,000 units per year. While the overall market for video walls is growing, most of this growth is going to narrow bezel LCD displays and fine pitch LED displays. He said the RP cube technology is used mainly in critical control rooms and TV studio back drops.

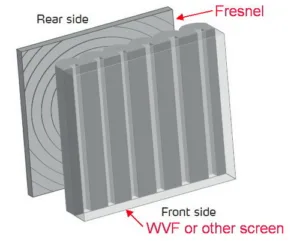

A rear projection screen actually consists of two elements, as shown in the image. The first is a fresnel lens and it is the rear element, closest to the optical engine. The focal length of the fresnel lens must match the distance between the optical engine and the screen. The purpose of the fresnel is to collimate the light from the optical engine so it arrives at the screen at normal incidence everywhere on the screen. In an ideal world, this would eliminate color and luminance discontinuities seen by off-axis viewers at screen boundaries. Lindegaard said that much of the residual discontinuities are due to chromatic aberrations introduced by the fresnel lens.

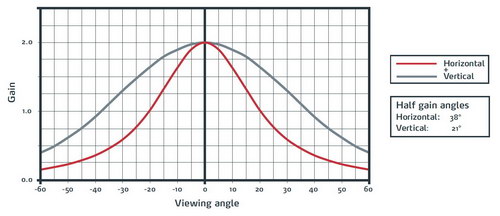

The second element is the screen itself. It is chosen by the user to match the needs of the installation, especially brightness, contrast and horizontal and vertical viewing angles. The narrower the viewing angle, the higher the gain of the screen and the brighter the image seen by an on-axis viewer.

Gain vs Viewing Angle for the new DNP WVF screen

The DNP WVF Screen fills out the gap in the DNP product range between the entry level Ultra Contrast Screen (UCS), and the high-end DNP screens, which include the Cross Prism Screen, the FXS Screen, the CSI Screen and the Black Bead Screen. All of these are standard products at DNP Denmark except the FXS screen. While this has only been sold to few selected customers, Lindegaard believes most of the cube manufacturers know about it.

The WVF screen, like all DNP screens except the Black Bead screen, is made from an acrylic styrene copolymer rather than pure acrylic. This is done because the acrylic styrene copolymer is more dimensionally stable under varying humidity conditions than pure acrylic. This stability allows DNP’s OEM customers to design cubes with very narrow gaps between screens, since they don’t have to allow for screen expansion.

The WVF, like other DNP screens and fresnel lenses, is available in a variety of sizes for 4:3 and 16:9 cubes. The largest size of WVF screen available is the 4:3 1600 x 1200 mm (63 x 47.2 inch) image area screen for an 80” RP cube.

Lindegaard says the DNP WVF is currently available to its OEM customers with 3 – 4 week delivery times. He said the WFV and other rear and front projection screens from DNP will be on display at the upcoming InfoComm in Orlando Florida, June 17 – 19. –Matthew Brennesholtz

Analyst Comment

InfoComm is a key exhibition for RP cube technology and Meko expects all of DNP’s OEM customers to be displaying their RP cubes there as well. (MSB)