Jun Zhao is CEO of TCL CSOT, one of the largest display panel makers in the world, gave an interesting keynote at the 2024 Display Week conference. In it he set out a very interesting future for his company based on largely on Ink Jet Printing (IJP) as a way of patterning the display materials.

He started by highlighting that the company has grown at more than 20% every year in its fifteen years of life. The firm is based in China but Zhao sees it as a global company as more than 60% of its sales come from overseas. It makes displays from 1” to 115” in LCD and OLED technologies as well as developing new systems such as emissive Quantum Dots (EL-QD).

He sees a good future for OLED although the overall growth of the industry has slowed right down with LCD demand reaching saturation. However, OLED has around 5% CAGR. Panels for OLEDs TV has stalled because of cost and after smartphones and TVs, OLED makers are going after the IT market of tablets and notebooks. There are big investments being made to add production capacity for IT OLEDs, but the high costs will hinder adoption by ‘ordinary consumers’, Zhao believes.

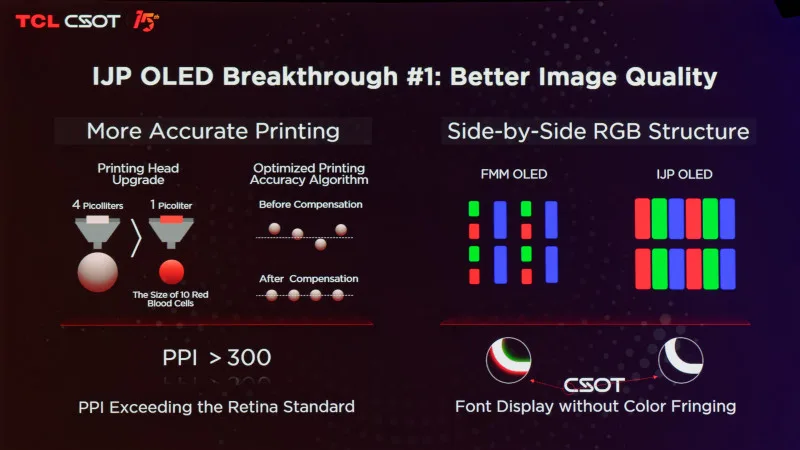

TCL CSOT sees a future for OLEDs that are created using IJP and has been working on the concept since 2013. Initially, there were a lot of challenges with low ppi, image sticking, high power and size limitations, but many of these points have been fixed. The firm has now got to a 10-9 litre drop size (1 picolitre – the size of 10 red blood cells!) which allows higher ppi and can reach 300ppi which is ‘good enough’. Vacuum drying helps with uniformity and power consumption challenges have been overcome with better materials.

Light Extraction

As often with displays, part of the solution is in getting the light out of the display efficiently and TCL CSOT has managed to minimize light loss. It has achieved lifetimes that match OLEDs made with Fine Metal Masks (FMMs). Compared to FMM, IJP allows 90% material utilisation against 30%. The number of processes performed under vacuum is reduced by 90% compared to FMM-produced OLEDs.

There is still work to be done, but TCL CSOT sees its future in IJP OLEDs, initially for IT applications and then potentially in the future for TVs and smartphones.

Zhao said that IJP OLED production at G5.5 will start in 2024. In the exhibition, the firm showed a medical display that will be the first product.

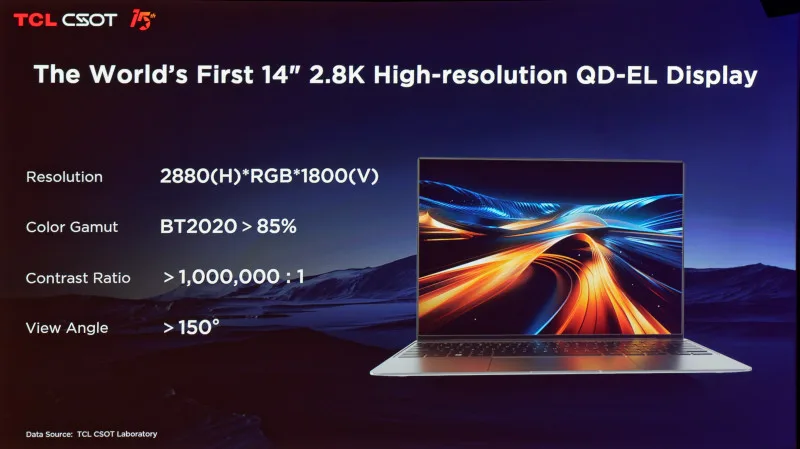

Looking further ahead, IJP can also be used for patterning electro-luminescent QD displays (EL-QDs) and these have better color, lower power and better reliability than OLEDs. It’s not just a concept, Zhao said (and several EL-QD displays were demonstrated at Display Week – editor). There are still some challenges to be overcome, especially with the lifetime of blue EL-QD materials and Zhao announced a $1 million prize for a good blue.

Finally, he said that IJP should stand for ‘Inspiring, Joyful, Pioneering’.