Automakers play a key role in the certification process for in-car displays. They set the initial requirements and specifications for the display, based on the needs of their vehicle and the preferences of their customers. They work closely with the display manufacturer to ensure that the display meets their specific requirements. This often involves a lot of back-and-forth communication, testing, and revision of the display design. They conduct their own testing of the display to ensure that it meets their standards and will function properly in their vehicles. This can involve testing the display in a variety of environments, such as in hot or cold weather, on rough terrain, or under different lighting conditions.

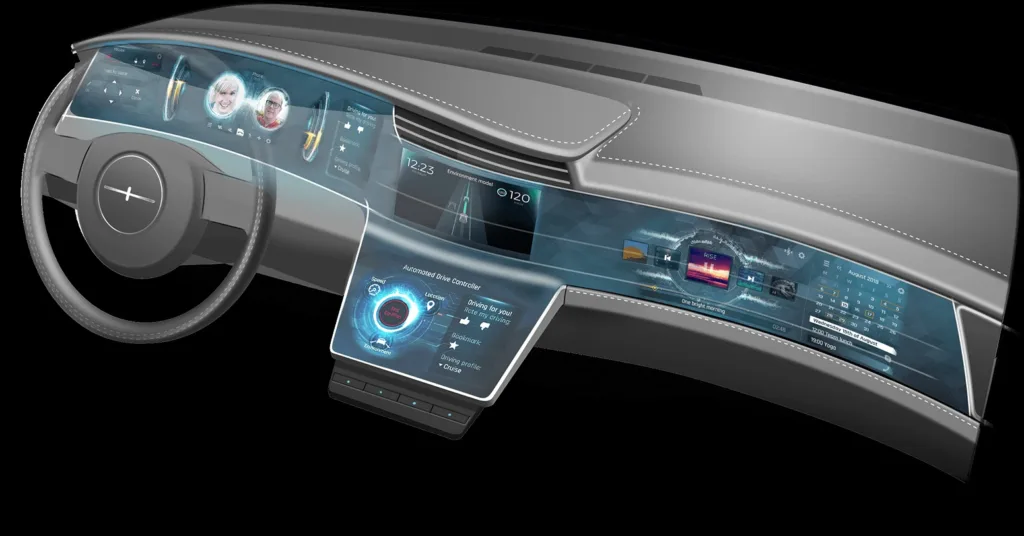

Beyond technical specifications, in-car displays are also evaluated for user experience factors like intuitive design, ease of use, and integration with other vehicle systems. This is important for ensuring driver safety and comfort. The requirements for in-car displays can vary significantly between different automakers, depending on their specific design philosophies and target markets.

While automakers do have their own internal testing and certification processes, there are a few reasons why they still need to involve outside organizations. These organizations provide standardized testing procedures and criteria that all automakers can follow, ensuring that the displays are tested in a consistent and objective way, regardless of the manufacturer. Having an independent, third-party organization certify the display gives automakers and consumers confidence that the display has met rigorous industry standards.

Certifying an in-car display is a complex and rigorous process. The car makers go to organizations such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO) for compliance and standardization. SAE and ISO are international organizations that can certify displays for use in vehicles around the world, ensuring that they meet the standards and regulations of different countries. In addition to meeting the standards set by organizations like SAE and ISO, in-car displays must also comply with regulations set by governmental bodies in different countries, such as the Federal Motor Vehicle Safety Standards (FMVSS) in the United States.

The display must undergo rigorous testing to ensure it meets safety, performance, and reliability requirements. This includes testing for durability, resistance to shock and vibration, electromagnetic compatibility, and compliance with automotive standards for electromagnetic radiation. The display must also meet specific requirements for visibility, readability, and functionality in various lighting conditions and environments.

In-car displays are subjected to extreme shock and vibration during regular use, so they need to be able to withstand these stresses without failing. To test this, the display is mounted on a shaker table that simulates real-world conditions, such as driving over rough terrain or hitting a pothole. The display is monitored for any signs of failure or damage during the test.

In-car displays must be resistant to electromagnetic interference (EMI) from other electronic devices in the vehicle, such as radios, navigation systems, and cell phones. To test this, the display is placed in an anechoic chamber and subjected to various types of EMI. The display is then monitored for any signs of interference or malfunction.

Well, the specifications for in-car display tests can vary depending on the type of display and the vehicle manufacturer’s requirements, but the common demands are universal:

- Visibility: The display must be visible in both direct sunlight and low-light conditions, with minimal glare.

- Readability: The text and graphics on the display must be legible and clear, even when viewed from different angles and distances.

- Durability: The display must be able to withstand extreme temperatures, humidity, and vibration without failing.

- Electromagnetic compatibility: The display must be resistant to EMI and function properly even when surrounded by other electronic devices.

- Functional testing: The display must be tested for proper operation of all its features, such as touch responsiveness, navigation, and audio playback.

These specs are just the tip of the iceberg – the actual requirements for a specific display can be much more detailed and complex!

- SAE J1757-1: Standard metrology for vehicle displays

- SAE J1757-2: Automotive head-up displays

- SAE J1757-3: Vehicle display system light efficiency

- SAE J2364: This standard covers the design and performance requirements for driver-vehicle interfaces, including displays, in hybrid and electric vehicles.

- ISO 15008: Specifies minimum requirements for image quality and legibility of automotive displays presenting dynamic visual information while the vehicle is in motion.

- ISO 2575: This standard covers the design and performance requirements for rear-view mirrors in passenger cars, including displays that are integrated into the mirror.

- ISO 16232: This standard covers the design and performance requirements for in-vehicle information and communication systems, including displays.

- ISO 16255: This standard covers the design and performance requirements for vehicle displays that present safety-related information, such as warnings and alerts.

That list doesn’t even begin to do justice to the requirements for in-car displays.

Actually, it is quite good to know that there are specifics to the requirements for displays. The display’s brightness must be within a certain range, for example, between 300-1,500 cd/m2 for direct sunlight and 50-100 cd/m2 for low-light conditions. The display’s contrast ratio must also meet certain standards, again, for example, between 800:1 and 1,500:1. These numbers may be common but not definitive and subject to variance depending on application. Very importantly, touch responsiveness must meet a certain standard for accuracy and speed, typically measured in milliseconds (ms). Driver response and engagement are key factors in automotive safety and no display can get in that way of that.

When it comes to automotive displays, if you’re a manufacturer, at least you know what you are up against, which isn’t necessarily the case in TVs or IT monitors where you can pretty much make anything you want to any level of quality that floats your boat or bank account. So, what drives the automotive display manufacturers’ business model? Is it price, design, adaptability, ruggedness, or what? Probably all of the above. A lot of companies are announcing or showcasing automotive displays, but to get those products to market isn’t easy, and it will probably get harder.

Apparently, cyberattacks on the automotive industry are increasing rapidly, targeting vehicles, components, and back-end infrastructure. To improve security, new regulations have been introduced like ISO/SAE 21434. Automobiles are a mass of electronic controls, sensors, displays, and computing units, all connected together so safety and security implications of display designs are probably going to become more taxing over time, as the industry comes to understand its vulnerabilities better. We are kind of entering a new age for automobiles, one in which the electronics outweigh the mechanics. It’s an opportunity for the display industry but not for everyone. It’s going to take a special breed of manufacturer to make the grade.