Technology development, improvements in materials as well as in manufacturing process, have enabled OLED display to gain higher market share. More developments are expected in next few years. After the strong consumer demand during covid times, the market has shifted into muted demand in 2023 due to macroeconomic factors. In spite of tremendous development in OLED display, luminance, life time, and costs have been challenges for the industry. Next generation OLED technologies are hoping to resolve these issues. It can be possible if technology developments and capacity expansions can enable cost reductions.

Phosphorescent OLED (PHOLED) Blue – Coming in 2024

In the OLED stack, the emissive layer is where electrical energy is directly converted into light. The emissive layer consists of a color defining emitter doped into a host. There are two main processes for OLED display. The first is to pattern red, green and blue OLED sub pixels in each pixel of the display as in RGB OLED display for smartphone. The other one is to produce white light in every pixel, and use a color filter to make red, green, and blue subpixel as in White OLED TV display (by LG Display). Samsung Display’s QD-OLED technology integrates printed red and green Quantum Dots (QD) with blue OLED. Then by using Quantum dot color conversion process, Blue OLED source light is down converted into red and green color. QD-OLED technology for TV and monitor was first introduced by Samsung Display in 2022. OLED displays are now used for TV, IT, smartphones, auto, wearables, VR and others.

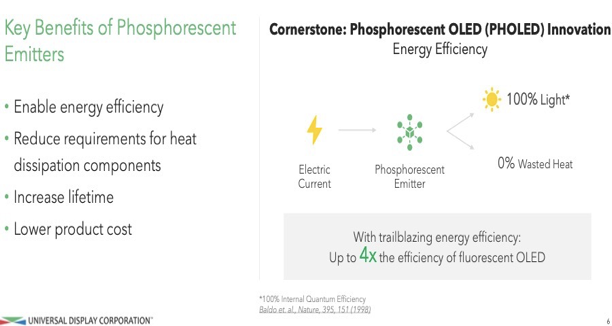

Currently phosphorescent materials for red and green and fluorescent materials for blue are used for OLED emitters. According to Universal Display Corporation’s published information, “Through the use of certain phosphorescent materials, our university partners at Princeton University and the University of Southern California discovered in the late 1990s, that up to 100% of the excitonic energy could be converted into light, compare to the 25% conversion with fluorescent materials”. Display industry has been waiting for more efficient blue phosphorescent materials for many years.

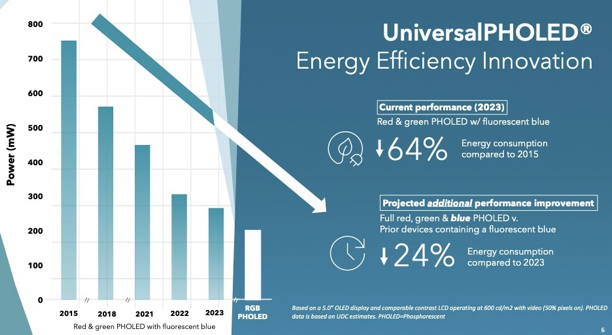

Mike Hack, vice president of business development for UDC said in a recent interview, “We at Universal Display (UDC) have already started sampling Blue PHOLED. We will have complete RGB PHOLED emitter products as well as host commercially available in 2024. We believe all roads to Phosphorescent Blue OLED will go through Universal Display Corporation. UDC has built a strong portfolio of patents and technologies and it is continously improving”. All Phosphorescent OLED emitters will help to increase energy efficiency, increase lifetime, reduce heat dissipation components and lower product costs. Higher efficiency or lower power consumption can extend battery life. Also, higher brightness at same power level can improve peak brightness. All Phosphorescent OLED emitters can be used in RGB OLED, WOLED and QD-OLED. It has the potential to improve efficiency, increase life time and reduce costs for all types of applications for OLED display. Success will depend on when it can be adopted for each application and if the potential for lower product costs can be realized soon enough to drive demand growth.

UDC is also doing R&D on Plasmonic PHOLED technology. According to Mike Hack “It is still developing. It is a new device structure. By using new Plasmonic device structure for RGBPHOLED, efficiency and life time of OLED can be increased”.

Gen 8.x fabs for IT- Mass Production in next 2 to 3 years

OLED suppliers are investing in 8.7 Gen fabs and high mobility IGZO backplane with low mask count to improve cost and have economies of scale compared to Gen6 fabs with LTPS backplanes. Samsung Display, LG Display and BOE are expected to bring Gen 8.7 fabs (in 2025 and beyond) to address larger OLED panels for tablets and ITs. Currently all smartphone OLED panels are using Gen 6 fabs, which are not efficient to produce medium size panels for tablets and notebooks. All three suppliers are planning to use Tandem structures (multi stack configuration) with Gen 6 Fabs in 2024 for higher brightness, longer life time and also to reduce power consumption (20% to 30%) especially for IT.

eLEAP & ViP Process – An Alternative Approach for Lower Costs

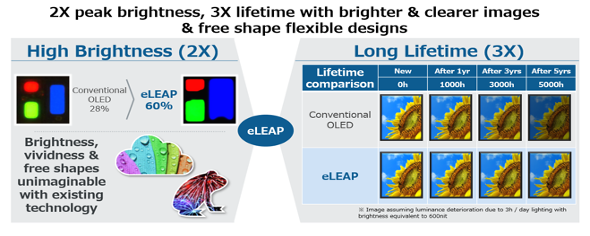

Japan Display Inc. has developed an OLED patterning technology that does not require FMM to pattern OLED RGB sub-pixels. Instead of FMM, the new methodology uses photolithography so that sub-pixel patterning accuracy exceeds conventional OLED displays. It can make the aperture ratio larger and it is scalable to all screen sizes for RGB OLED display. Japan display has proven this new technology in half Gen 6 OLED evaporation line without using FMM. The eco-friendly new photolithography-based OLED patterning technology eLEAP can reduce significant amounts of chemicals used during the OLED display manufacturing process. eLEAP can be used in a very wide range of applications.

Visionox has introduced Visionox intelligent pixelization (ViPTM) technology to replace FMM for deposition and patterning. The subpixel patterning has been realized by photolithography. FMM process is the dominant technology for smartphones, tablets and notebooks where higher PPI is required. According to the company ViP addresses challenges of FMM by providing larger aperture ratio, longer life time, lower power consumption, better luminance uniformity and many other advantages.

Other Technology Developments

LG Display have been introducing new technologies to improve OLED’s brightness and display performance. LGD’s OLED.EX technology used deuterium to replace normal hydrogen in the OLED layer and made it more heat and electricity-resistant. LG Display’s 3rd generation OLED meta technology comprises a ‘Micro Lens Array’ that maximizes light emission from the OLED panel and ‘META Booster,’ a brightness-enhancing algorithm. According to LGD based on META technology, their latest OLED displays can achieve 60% brighter images and 30% wider viewing angles than conventional OLED displays.

For 2023 Samsung Display has introduced QD OLED with hyper efficient EL material, advanced optimization algorithm InteliSense AI, graphite heat sink and advanced Cd Free quantum conversion material. HyperEfficient EL could achieve 33% more color and brightness reaching >2000 nits. According to Chirag Shah, Senior Director Marketing Business development for Samsung Display, “QD-OLED display with blue self-emitting pixels, top emission and quantum dot color conversion can provide superior color performance. In 2 years, it has positioned itself as the best TV technology.”

New technologies are also being introduced for OLED display. For example, Craig Bandes, CEO of Pixelligent (advanced nanomaterials manufacturer) presented at Display Week 2023 Business Conference and said that their PixClear and PixJET products improve OLED Display clarity, brightness and efficiency. According to Mike Helander, CEO of OTI Lumionics, during a presentation at the Display Week 2023 Business conference, “OTI has developed optimized panel designs using CPM patterning to increase pixel efficiency to reduce burn-in in OLED”. CPM patterning can enable under display camera. OTI technology is mass production qualified by multiple panel markers.

OLED technology is poised to resolve luminance and lifetime issues with development in materials and manufacturing processes. If technology development combined with capacity expansion can reduce cost, it can drive strong demand growth in future years.

Sweta Dash is the founding president of Dash-Insights, a market research and consulting company specializing in the display industry. For more information, contact [email protected] or visit www.dash-insights.com