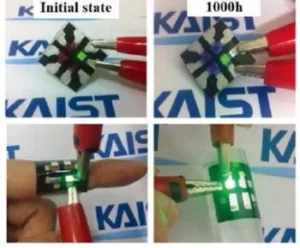

In case you missed it, sometime between cooking that turkey and ordering your first Christmas gift, the folks at Korea’s national research lab KAIST said they’ve developed a process that can lead to wearable fabric-based displays. Using standard evaporation equipment to deposit an OLED substrate on fabric, the thin film encapsulation process generates OLED lifetimes of over 1K hours on the fabric that out-flexes traditional plastic substrates.

The use of fabric as a display is not new. Back in 2013 Netherlands-based Holst Center showed iron-on flexible OLED display integrated into a wireless sensor area network woven into clothing (in this case, an OLED-lit T-shirt.) Holst said the OLED could withstand the high temperatures of a hot iron press (see image.)

Future applications include medical use including heart rate sensing or creating a full body area sensing network where the apparatus is embedded in anything from a patient gown to a space suit. Other options can extend to wet suits for underwater OLED lighting for example, but this is still much different than the KAIST solution developed above.

OLED display ironed onto textile as early as 2013 at EU-based Holst centerBut the future of fabric displays will move beyond niche applications such as medical, and eventually move into consumer fashion according to Professor Joanna Berzowska, of Montreal, Canada-based Concordia University’s Department of Design and Computation Arts. Its Karma Chameleon ‘smart garment’ project began in 2013 to create clothes that could change the way a garment looks based on sensor input that could be influenced by a wearer’s stress level or mood, for instance. But this, too, is a long-term project. The group said it expects first generation garments where the area changing appearance is relatively small or limited; instead of aiming to create something that will completely change dependent on the wearer’s mood or taste.

OLED display ironed onto textile as early as 2013 at EU-based Holst centerBut the future of fabric displays will move beyond niche applications such as medical, and eventually move into consumer fashion according to Professor Joanna Berzowska, of Montreal, Canada-based Concordia University’s Department of Design and Computation Arts. Its Karma Chameleon ‘smart garment’ project began in 2013 to create clothes that could change the way a garment looks based on sensor input that could be influenced by a wearer’s stress level or mood, for instance. But this, too, is a long-term project. The group said it expects first generation garments where the area changing appearance is relatively small or limited; instead of aiming to create something that will completely change dependent on the wearer’s mood or taste.

Parasitic powered displays on the body are expected that can change illumination and color that responds to the wearer’s movement and the power [energy] that is produced as a result. “Our goal is to create garments that can transform in complex and surprising ways – far beyond reversible jackets, or shirts that change color in response to heat.” In the future, when someone says you look hot in an outfit, then, it might just take a literal meaning.

Another direction the market is taking is woven electronic threads from ARACON in the form of e-textiles. Here complete solutions of woven electronic fabric-like material are being used in low weight EMI protection applications for aircraft. To get there, the group developed conductive yarns or fibers they claim are “ideally suited for use in textiles.” The material combines a DC resistance of less than 1 ohm per foot in a diameter of 0.014 inches and with the strength of Kevlar. Conveniently, its material can also be made “undetectable” when woven into a fabric.

It’s clear we are just at the beginning of truly wearable displays, with plenty of applications and new markets yet to be uncovered as the full benefits become evident. I see the KAIST announcement, that leverages traditional encapsulation techniques to empower fabric displays, as a milestone on the road to our wearable future. – Steven Sechrist