I had hoped to ‘get caught up’ this week having spent a couple of days in Germany at the Fujitsu Forum and seeing clients. I had managed to get the Electronica report written up, but underestimated the time it would take to process all the pictures and get the stories onto the website. We continue to work on the website and after the major template change, we think we have made the site much easier to use for reading stories. We have also added some RSS feeds that allow you to use a reader (I use my Postbox email application) to get advice when we publish a story.

As well as work on the website we’ve done quite a lot to improve our production process for the pdf newsletters. However, we’re still struggling to get an optimum balance between what works on the page and on the website. There are real contradictions between the two mediums that make it hard to get both perfect. The work we did on the pdf were to allow us to use InDesign. From here, we plan to start to look at the design to see if we can improve it. I knew an artist who said that they thought that they had never finished an oil painting. They simply had to abandon it. Websites and newsletters are a bit like that – they are never complete and there’s always a reason to polish or tinker!

We’ll have the report on our visit to the Fujitsu Forum next week. However, it did occur to me that much of what I (briefly) looked at in VR and data tracking would have felt a little bit like science fiction just a few years ago. We’ve been watching what the company has been doing with A/R for professional applications such as plant maintenance. The demo we got in Munich showed how the company can integrate very accurate (within 30 cm) positioning technology together with wearable technology, A/R and cameras to track the actions and many vital signs for the wearer. The sheer scale of the data that organisations can collect is incredible.

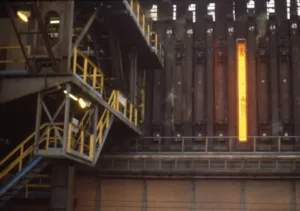

My first job after I left university was in the steel industry. Although I was just employed at a desk, I regularly visited the factories that were hot and potentially very dangerous. Had today’s technology been possible then, so much could have been done to track the conditions for workers and help them to do a better job in conditions that were often very demanding and dangerous.

I was on a training course once, with some managers from the ‘coke ovens’ – huge structures where coal was baked to be used in the blast furnaces that converted iron ore to iron. We were discussing some subtle point of personnel management. One of the managers from the coke ovens (which were very hot but were in the open air and ran 24/7, so sometimes needed to be inspected from above, with the bottom half of you freezing, while the top half might be in a gale or snowstorm) pointed out to me that at 3:00 am on a public holiday in December and when you needed something done was when you really started to learn “industrial relations”!

In those days, the technology was, frankly, not much beyond 19th century! It would have been hard to imagination how much safer conditions could be today.

Bob

Coke Ovens in South Wales in the 1980s