Bernhard Lutzer from In-Vision Digital Imaging Optics gave a nice presentation on the art of lens design for curved screens. He discussed the basic of optical materials, optical diffraction and projection lens design including the use of sophisticated ray tracing. All this can lead to an optimization of the optical parameters, but this is not sufficient. This is where the art of lens design comes in. Here, the experience of the lens designer can tell if the materials selected are cost effective, if the parts can be manufactured to the desired tolerances and if the design is “good enough.” Plus, the design has to be transferred to a mechanical design group to fit the optics into a housing, where more experience often guides the choice of optics.

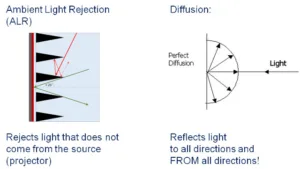

James Fife of rpVisuals then continued this “art” theme by talking about screen technology. He focused mainly on explaining the differences between diffuse and ambient light rejecting (ALR) screens (they are a reseller of the DNP Supernova ALR screens).

For simulation applications, a deep black level is needed and you can’t create more contrast by over specifying the brightness. He went through some typical contrast calculations showing how an ALR screen can deliver higher contrast with lower lumen projectors. He said that the higher cost of the ALR screen coupled with the lower cost of the projectors (due to lower lumen requirements) is still lower cost than a conventional diffusion screen and a higher lumen projector. While this argument may hold water in a conference room setting, where the ambient light sources are overhead, it will be less effective in a simulation environment where the contrast-reducing light sources come in horizontally from other parts of the curved screen.

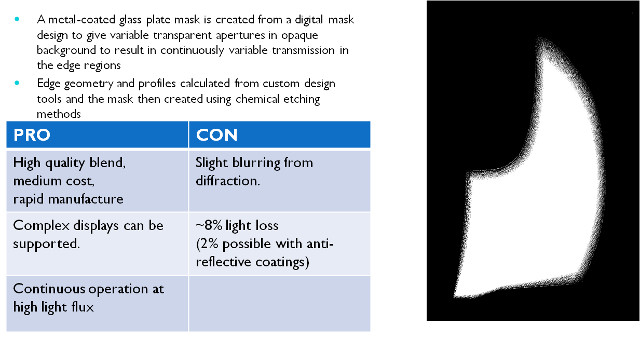

Geoff Blackham of GBvi Ltd. talked about optical blending. His presentation gave a very nice overview of the many ways one can reduce the light where two projector images overlap in a multi-projector blended installation. For daylight simulation applications, digital blending where the image brightness is reduced electronically in the overlap area may be acceptable. But for low light level applications, optical blending, which are physical elements placed in the light path, are needed.

Blackham then described a large number of methods that can be used to design these light blocking plates and the various patterns that can be used – along with the trade-offs of each design. There were far more options that most attendees had realized. His company specializes in these designs.

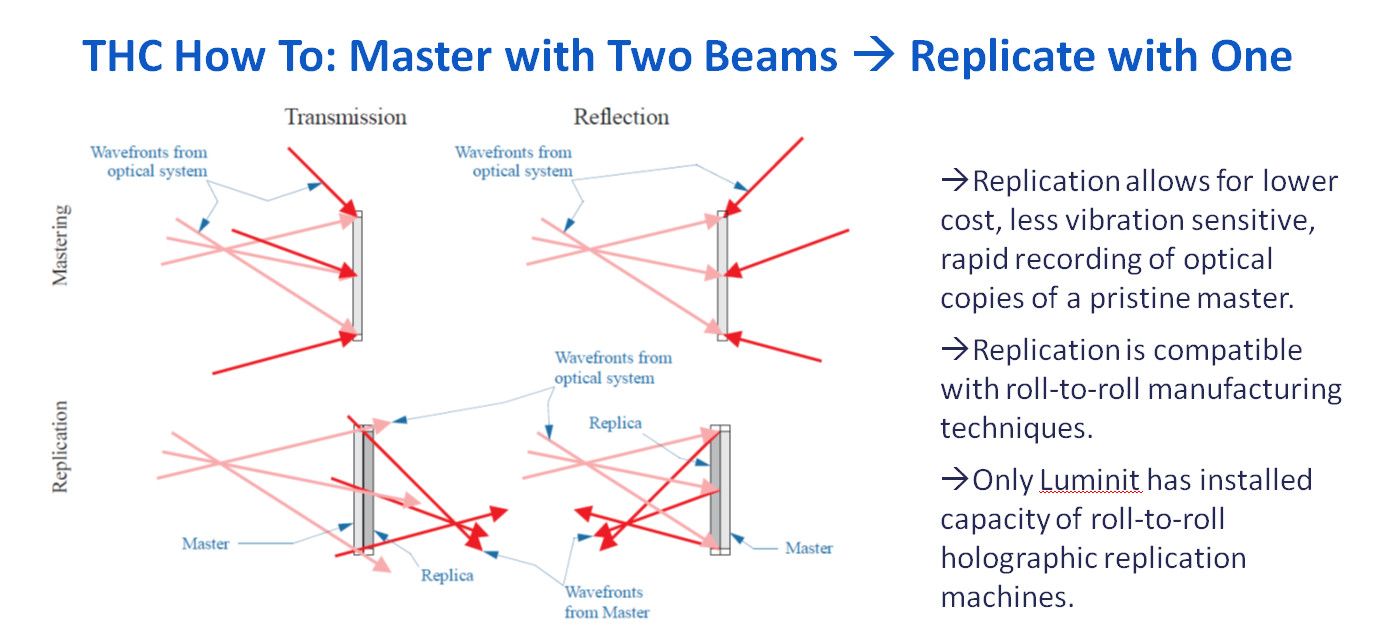

Seth-Coe Sullivan from Luminit used his time to talk about the firm’s light shaping diffuser (LSD) technology. This is a holographically recorded pseudo-random pattern of micron-scale shapes designed to direct light in various ways. For example, they supply the 1º horizontal by 60º vertical diffuser used by Holografika and Third Dimension Technologies. It also forms the basis of their Crystal screen technology.

Importantly, the LSD technology starts with a holographic master, but this can be replicated by hand for custom jobs, or roll-to-roll, roll-to-sheet and even injection molding processes – something he thinks no other company can do. These diffusers are already in many products ranging from automotive to lighting to aircraft.

He then turned to what they can offer for augmented reality, which are essentially thin diffractive optical layers for waveguide applications for use in image injection and image extraction. Sullivan said Luminit can make both surface-relief holograms or volume holographic elements like lenses or grating (they call this THC – you catching the drug-related naming themes?).

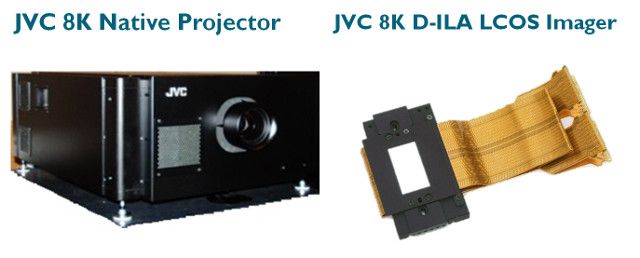

Jack Faiman from JVC Professional talked about 8K projection. The company offers an 8K native projector based upon a trio of 1.3” LCOS imagers and also produces an 8K e-shift projector that uses 0.69” 4K imagers.

Why go to 8K, he asked? One big advantage is the ability to eliminate some projectors from the simulator saving costs (capex and maintenance), removing blends and maybe increasing image fidelity depending upon how it is implemented. JVC offers an 8K native projector for the simulation market now.

Alternatively, one can use an 8K e-shift projector that will offer fidelity in between a 4K and native 8K image, but at much lower cost. The 8K e-shift can run at 120Hz but requires 4 DisplayPort connectors. The 8K native unit can also run at 120Hz but requires 8 DP 1.2 or 32 HDMI 1.4 connectors. The choice of 8K native or e-shift depends upon many factors, including the capabilities of the image generator and underlying database.

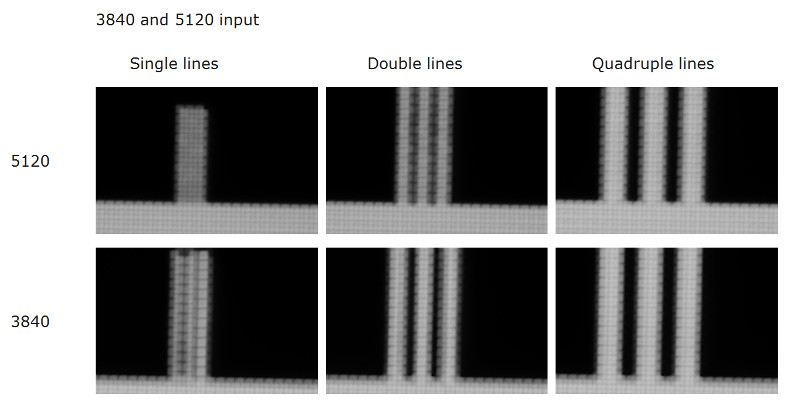

Svein Arne Jervell Hansen from Barco was the last presenter in the session. He also talked about the trade-offs between native and pixel-shifted projectors, but focused on their 3-chip DLP solution that uses DMDs with 2560×1600 resolution. He noted that their algorithm can create a 5120 x 3200 processed image, but only a 4096×2160 image is sent to the DMD for image shifting. This allows for a higher contrast modulation. This was illustrated as sharper line edges, especially on the double line input as shown below.

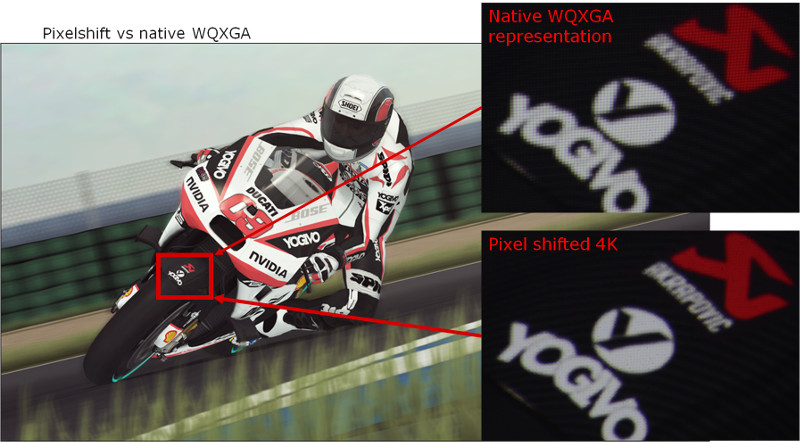

Improvements in the image vs. the native WGXGA were then shown as below.

The session provided very good information about the trends, technologies and issues with the simulation market. – CC