In paper 25.2 (High-Brightness Solid-State Source for 4K Ultra-Short Throw Projector), Sony described improvements they have made to the laser phosphor material that will improve projector brightness and lifetime. This is destined for their 4K short-throw projector that is used in homes and professional applications, but it will not be implemented in products until the end of the year.

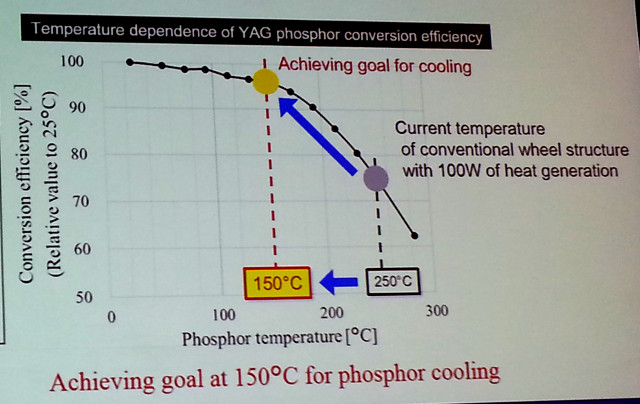

Sony said the problem with laser-phosphor projectors is that as you increase the blue laser power, the conversion efficiency decreases. That’s mainly a result of the increase in temperature, which also accelerates the aging of the phosphor. Keeping the material cool is key.

In their development project, their goal was to lower the operating temperature of the current LP projector material from 250ºC to 150ºC. This goal was accomplished with two improvements.

One was the modification of the rotating wheel to add a second fin that allowed more air cooling to occur. This achieved the desired 150ºC phosphor material temperature at a 130 W/mm² radiance level.

The second improvement was a change in the phosphor material binder. Here, Sony noticed that the resin binder can be damaged with high optical loads. As a result, Sony changed to an inorganic binder. This was tested at optical loads as high as 350ºC without degradation. At 150ºC, the output was very stable over a 7,000 hour actual testing period (not accelerated).