Samsung is lining up to launch its next smartphone (which forecasters are calling the ‘S8’) and last week we saw a report that it would use a touch technology called ‘Y-OCTA’, used in the Note 7. But what is Y-OCTA touch technology and why would Samsung want to use it?

We came across an explanation of the technology from David Hsieh of IHS and have reproduced it here with his permission.

For manufacturers of smartphone organic light-emitting diode (OLED) panels, especially Samsung Display, advances continue to be made to integrate touch-panel structures into displays in order to achieve film integration and reduce panel thickness. The evolution is especially prominent in comparing rigid OLED panels to flexible OLED panels—an integration that creates the possibility of a very thin panel that can be foldable and even rollable.

As analyzed in the report Touch Sensor Technology & Market Report – 2016, on-cell touch solutions bring the display market a step closer to flexible products, and is a fundamental technology of the Y-OCTA mechanism. In essence, Y-OCTA does away with a separate touch-screen layer on displays by integrating the touch-sensitive part of the screen to the unit.

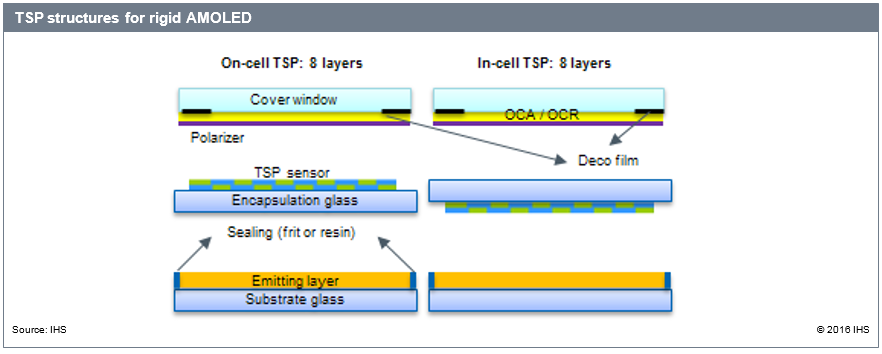

On-cell TSP for rigid OLED

The diagram above shows the traditional structure of a rigid OLED display, in which the on-cell with a touch-sensor panel (TSP) can be found on the surface of the encapsulation glass. The rigid OLED panel itself has two glass substrates—the encapsulation glass and the substrate glass on the backplane.

Between the encapsulation and backplane glass is a seal (made of frit or resin) for encapsulation; the TSP sensor is on the surface of the encapsulation glass. On the cover window side, the OLED polarizer and the cover window are laminated by optical clear adhesive (OCA) or optical clear resin (OCR). In this case, the TSP is on the topside of the encapsulation glass.

Overall the entire OLED module has eight layers, including touch and cover window. From top to the bottom, the layers are as follows: cover window, deco film, OCA/OCR, polarizer, TSP sensor, encapsulation glass, OLED emitting layer and backplane substrate.

In-cell TSP for rigid OLED

In this structure, the TSP moves from on-cell to in-cell, so that the TSP sensor is on the underside of the encapsulation glass. Aside from the location of the TSP, the structure for in-cell is basically the same as that, however, of the on-cell TSP for rigid OLED.

The eight layers remain unchanged, but the sequence now differs slightly. From top to bottom, the layers comprise the following: cover window, deco film, OCA/OCR, polarizer, encapsulation glass, TSP sensor, OLED emitting layer and backplane substrate. With this structure, in-cell touch shows better sensitivity and response.

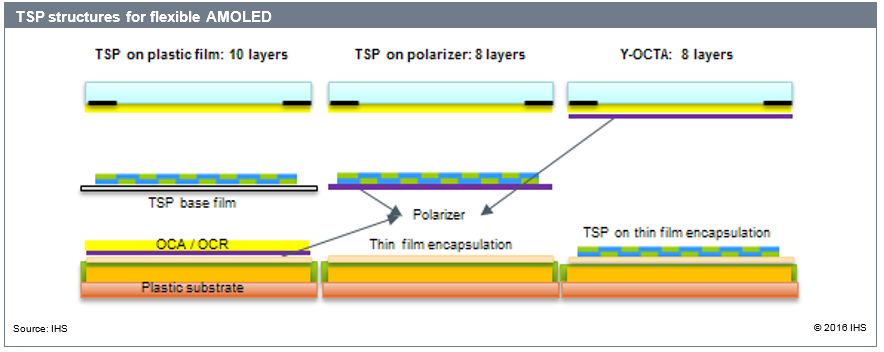

TSP sensor on plastic film

For a flexible OLED display, a plastic substrate is used instead of a glass substrate. In theory, it is not possible to make a TSP sensor layer on a plastic substrate. As a result, flexible OLED panel makers, especially Samsung Display and LG Display, have developed a special plastic layer called the TSP base film. Included only to serve the touch TSP sensor, the TSP base film is laminated with the OLED panel using OCA/OCR.

Owing to the addition of the TSP base film, the entire structure has 10 layers. From top to the bottom, the 10 layers include the following: cover window, deco film, OCA/OCR, TSP sensor, TSP base film, OCA/OCR, OLED polarizer, encapsulation layer, OLED emitting layer and backplane plastic substrate. Because there are more layers, the structure is more complicated, and so panel makers are starting to look for a better solution.

TSP sensor on polarizer

Using TSP on plastic film is complicated by the addition of the TSP base film, so the new idea is to combine the TSP base film with the OLED polarizer. Through the development and the adaptation of thin-film encapsulation (TFE), and by combining the polarizer and the TSP base film, the OCA/OCR layer is no longer needed for lamination. This successfully reduces the number of layers from 10 to eight.

The eight layers, from top to the bottom, are: cover window, deco film, OCA/OCR, TSP sensor, OLED polarizer, thin film encapsulation, OLED emitting layer and backplane plastic substrate.

Y-OCTA: TSP sensor on thin-film encapsulation

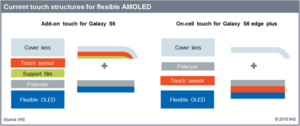

As currently the most advanced structure, Y-OCTA is a term developed by Samsung Display to describe the special structure for a flexible display, as described in the article On-cell touch solution, a big improvement for flexible AMOLED (IHS Subscription required). The most important feature is putting the TSP sensor directly on the TFE to achieve an on-cell solution. On-cell has the following advantages over add-on touch:

- With on-cell, the optical features have been improved on both the touch and curved areas as the touch layer is below a polarizer, allowing makers to use non-indium tin oxide (ITO) materials for the transparent conductive film.

- The polarizer is placed closer to the cover lens, resolving some of the visibility issues apparent on curved edges.

- The on-cell type does not need a support film, which had the undesired effect of preventing the touch layer from being flat on a curved area while being transferred to module makers. Eliminating the support film reduces total panel thickness, production costs and lamination processes.

- The on-cell structure is more suitable for flexible products because the structure has fewer layers compared to the add-on type.

The structure is as follows:

In this case, the eight layers from top to the bottom are in this order: cover window, deco Film, OCA/OCR, polarizer, TSP on thin film encapsulation, thin film encapsulation, OLED emitting layer and plastic substrate backplane.

The Y-OCTA structure is applied to the latest flexible OLED panel used for the Samsung Galaxy Note 7 Edge. “Y” stands for “Youm,” which is what Samsung calls its flexible AMOLED technology. Samsung Display gained a strong foothold in the smartphone market through its OCTA technology, and it hopes to stay ahead of its competitors in the flexible OLED market as well, which is why it adopted flexible touch solutions for the Galaxy S6 and subsequent models.

It may be true that Samsung Display opted for the on-cell touch as a transitional technology to shift toward Y-OCTA. However, the company seems to have considered the development trends of component suppliers and new panel makers, which is more likely the decisive reason for the choice. Moreover, the on-cell structure can be as innovative as Y-OCTA, especially if makers are able to reduce the number of polarizers and touch layers.

The original version of this article was originally published on the IHS Blog.

David Hsieh is Director of Analysis & Research within the IHS Technology group