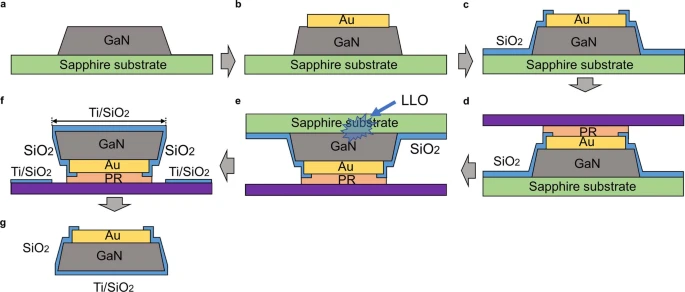

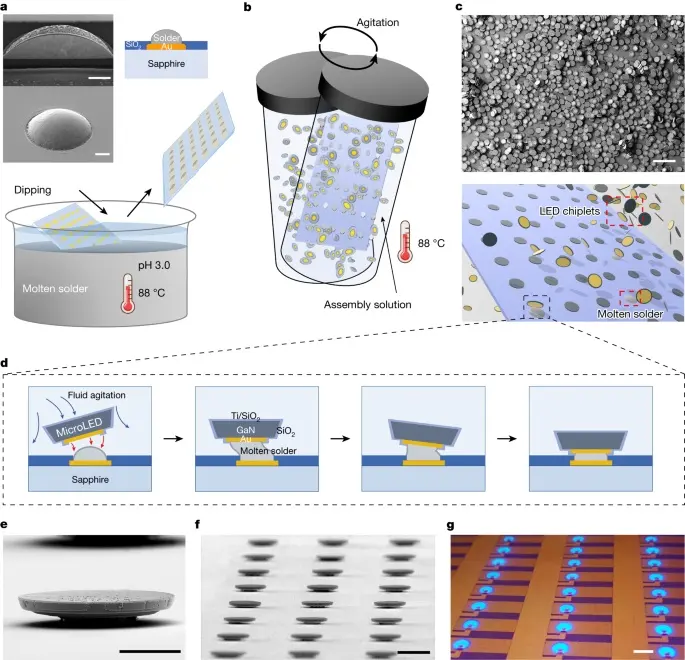

A team of scientists from Seoul National University (SNU) and LG Electronics in Korea has made significant strides in the development of an efficient method for manufacturing MicroLED displays. In a recent article published in the peer-reviewed journal Nature, the researchers described their new technique, which they believe is a strong candidate for industrial-scale production of large MicroLED displays. The team’s approach, known as fluidic self-assembly (FSA), uses a shaking motion to position and bond microscopic LED chips, or chiplets, onto a substrate.

Traditionally, manufacturing MicroLED displays involved manually picking up and placing individual chiplets onto the substrate, a slow and time-consuming process. However, by implementing FSA, the team achieved impressive results, assembling a two-inch blue light-emitting panel with over 19,000 chiplets in just 60 seconds.

The analogy used by lead researcher Lee Dae-won from SNU illustrates the principle behind FSA: imagine a box filled with liquid and numerous small puzzle pieces floating inside. When the box is shaken, the pieces naturally find their designated slots, much like how the LED chips find their spots on the substrate. By carefully controlling the viscosity of the liquid, the researchers were able to achieve an assembly success rate of up to 99.9 percent.

According to the study, conventional manufacturing methods would take a robotic machine 300 days to produce an ultra-high-definition MicroLED display through the pick-and-place process. The adoption of FSA not only accelerates the manufacturing process but also reduces costs, making it a promising solution for large-scale production.

Lee Dae-won mentioned that while their technique shows great potential, several factors will influence the time it takes for the product to reach the market. Advances in manufacturing technology, scalability of the production process, and market demand will all play a role. He estimated that it could take around five years for the technique to be fully implemented in commercial displays, such as smartphones, tablets, smartwatches, and augmented reality devices.

The development of an efficient and cost-effective method for MicroLED display manufacturing is of strategic importance for Korea, as it aims to regain its position as a global leader in the display sector. In 2021, China surpassed Korea, holding a 42.5 percent market share. To reclaim the top spot, Korean display companies, including Samsung Display and LG Display, plan to invest more than 65 trillion won ($48.77 billion) by 2027 in securing innovative technologies and expanding OLED display production lines.

Reference

Lee, D., Cho, S., Park, C. et al. Fluidic self-assembly for MicroLED displays by controlled viscosity. Nature (2023). https://doi.org/10.1038/s41586-023-06167-5