In my first DD after the end of the madness that is CES, I would normally pick out a few highlights. However, I had one meeting that really surprised me from a company that I hadn’t previously met with, a chip company, SigmaSense, which seems to have the potential to significantly disrupt the touch market.

I have to warn you. I have spent much of the time since my meeting with the company, in one of the hotels just outside the Convention Center, trying to work out where the catch or ‘gotcha’ is, because the company not only claims huge improvements in three different areas of capacitive touch, but, it seems to me has the potential to move touch to a new level. Surely a small start-up from Austin can’t be this disruptive? I’ll return to the ‘big picture’ later in this article, but lets look at the claims.

Speeding up Sensing

SigmaSense uses a technique borrowed from the circuitry used for noise cancelling headsets. Using this concept, it continually senses impedance changes across the whole touch surface. That’s in contrast to traditional sensing systems that perform their analysis of touch in a series of scans, typically in the 30 to 60Hz range, although that will depend on a lot of system variables. SigmaSense senses continuously, but samples and reports the data 300 times per second. The firm told us that it, effectively, ‘oversamples at megahertz rates’. This can significantly reduce the latency of touch systems which could be really important for gaming, but also for touch systems that need to be as responsive as possible – for example in transport or medicine.

Signal to Noise

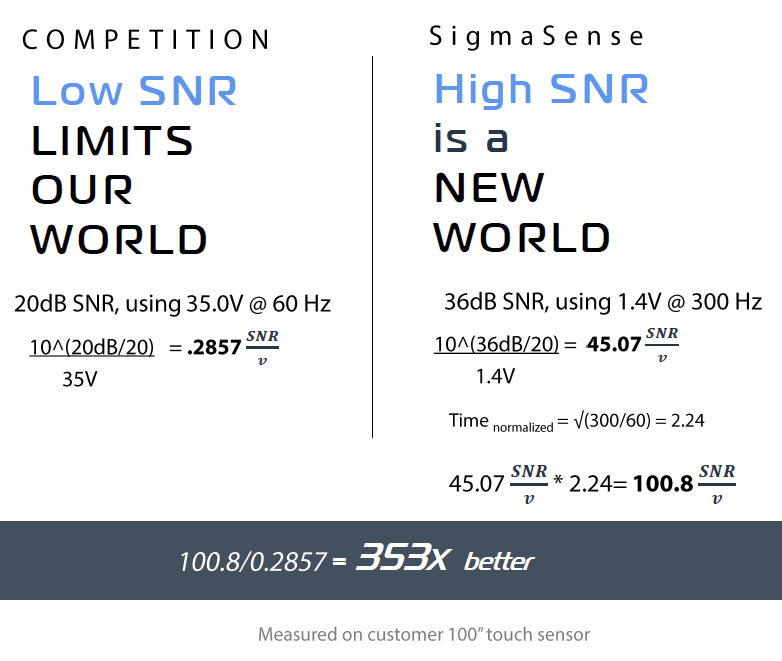

The second claim is ‘multiple order of magnitude improvements’ in signal to noise (SNR) ratio (said to be 100 to 1000 times better). Not only that, SNR for conventional is often measured and quoted over a 3 second average, so the signal is detected only after a fair bit of smoothing. SigmaSense would like to get people to quote SNRs in context with time, and voltage. If you do that, then the firm’s claims for multiple orders of magnitude look realistic.

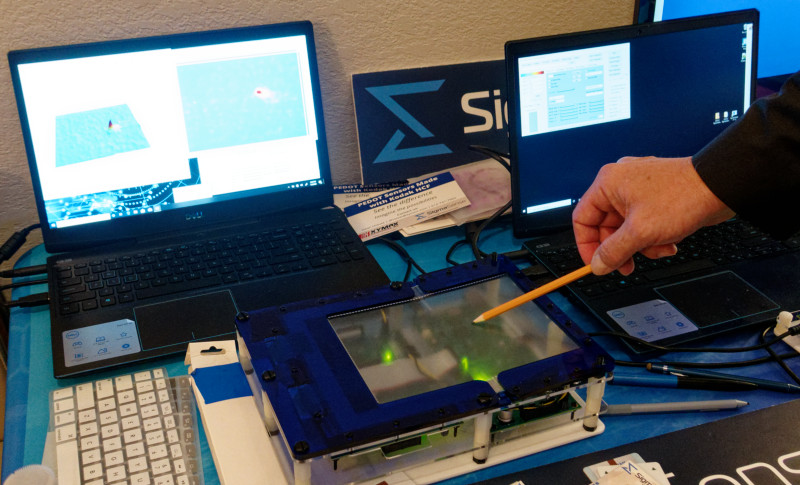

So what does a dramatic boost in SNR do? First, you can detect hover at long ranges from the touch surface. That means that you can start to optimise the display for a touch or interaction well before the user’s hand or finger gets to the surface. You can also use different objects, such as a regular graphite pencil as a very effective stylus.  A simple pencil gives quite a strong signal. Image:Meko

A simple pencil gives quite a strong signal. Image:Meko

Of course, the use of a Wacom pen or Microsoft pen gives a very strong signal. You can also recognise objects of different shapes that have been placed on the surface, without needing special material on the bottom. An impressive demo was of a simple plastic water bottle sitting on the surface. The system could even show clearly when the bottle was squeezed, as the shape of the bottom of the bottle changed by flattening. Another demo showed how the graphite drawing from a pencil could be read through the paper.

This demo showed that not only could detect a pencil, but could detect graphite, through the paper. Cool! Image:Meko

This demo showed that not only could detect a pencil, but could detect graphite, through the paper. Cool! Image:Meko

Of course, improving the SNR also means that the system works well even with very thick gloves or with water or other liquid contamination. Touch systems can also be built that will work through thick glass windows – ideal for retail applications (and the original application of PCap touch).

The controller can measure self and mutual capacitance at the same time. One of the numerous demos shown was of a sheet of paper with graphite numbers drawn with a pencil being laid, paper down on the surface. The numbers were clearly legible – with the touch detecting the graphite through the paper. Improving the SNR also means that capacitive touch is much easier to implement on large displays without the need for metal mesh electrodes. Further, the extra ‘headroom’ means that panels that might otherwise have been rejected because of defects or inconsistencies and non-uniformity in their (usually ITO) electrodes are no longer scrapped. That benefit alone, can change the economics of large PCap touch displays by significantly improving the manufacturing yield.

As well as coping with material variability, sensor geometry becomes significantly less critical, which means that simple patterning processes such as touch screen printing can be used.

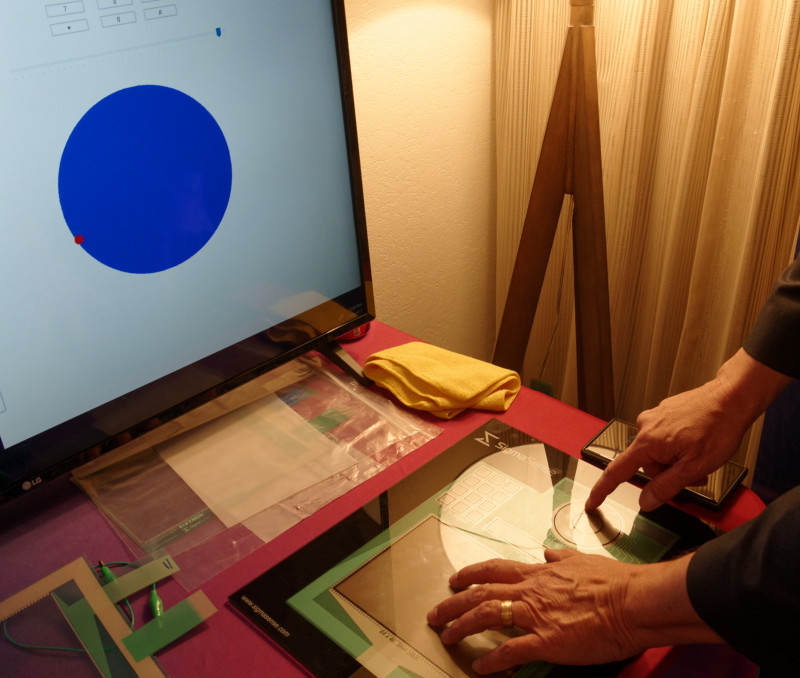

The strong SNR performance means that the channels can be used to track touch on more than one surface. This means, for example, that a touch surface could be wrapped right around a smartphone, allowing the back to be used for different controls (such as audio) and the sides to be used as additional controls. That would just need a single controller chip and is a significant help to smartphone makers that are trying very hard to develop devices with no apertures at all.

(sorry if I’m a bit breathless, but this seems to me a big story!)

In this demo, multiple touch areas on a single sensor were controlled by a single chip. Image:Meko

In this demo, multiple touch areas on a single sensor were controlled by a single chip. Image:Meko

Dramatically Lower Voltages

The third big deal is that the controller can operate at extremely low voltages. As well as reducing power, it means a dramatic reduction in EMI. Further, it can solve some issues in touch materials. For example, silver nanowire conductors, which have been developed to act as better electrodes have issues with the development of small whiskers of silver (known as dendrites) that change the properties of the electrodes. These are dependent on voltage, so reducing the voltage reduces the production of the whiskers and improves the reliability and lifetime of the electrode layer. Furthermore, alternative materials can be used. SigmaSense told me that it could run a 100″ display with a touch voltage of just 1V. It can also build sensors with polymers, perfect for flexible displays. An impressive demonstration showed that the touch signal hardly varied as a sample substrate was flexed.

SigmaSense is around 3.5 years old and has a fabless model, using TSMC as a fab. It is based in Austin, Texas and has 33 staff. It will make chips, boards and modules for sales and wants to disrupt the current controller business. The first target is the large screen market, where the voltage and noise advantages should really reduce costs quickly. After that, it will promote its technology for IWBs and then tables/TVs (a category that we saw elsewhere at the show. If you can add good cheap touch to a TV, it can become a gaming surface for play, potentially a big market).

Analyst Comment

Over the years, I have used the phrase ‘if they can do what they say they can do’. That’s appropriate this time. It’s not that I have any reason to doubt the claims of SigmaSense, but I had just an hour or so in a suite to look at some demonstrations, and the claims are very big indeed. However, I saw a good number of live demonstrations that would have been very hard to manipulate, so, until I hear otherwise, I will remain persuaded that SigmaSense, at the very least, has a technology that any company in the touch field should be checking out. In fact, if the company does have the kind of disruptive technology that it seems to, its biggest challenge might be to deal with the demand for its time and resources from potential clients (and threatened competitors).

The second point is that the huge amount of data that the firm can collect looks ideal for feeding all the neural network/AI technology that is developing in the Tech world. I wonder what new touch facilities can be developed by those that get access to that huge level of accurate touch and object data?

I’m tempted to say ‘touch wood’ that SigmaSense is telling the truth, but the firm would probably tell me it could enable that as well! (BR)