With the absence of in-person conferences we miss out on the personal nature of attending an event. Shaking hands, chatting, meeting new people, awkwardly trying to remember someone’s name or how you know them. Yet we continue to “attend” the virtual conferences because, presumably, there is still value to be had. Nearly all the “value” is now in the information being shared, which is generally pre-recorded presentations and pdf PowerPoint files. So, to pass along the most value to you, the readers, I will share a series of photos from the talks of the Phosphors & Quantum Dots Industry Forum 2021 along with my insights. Enjoy the photo blog!

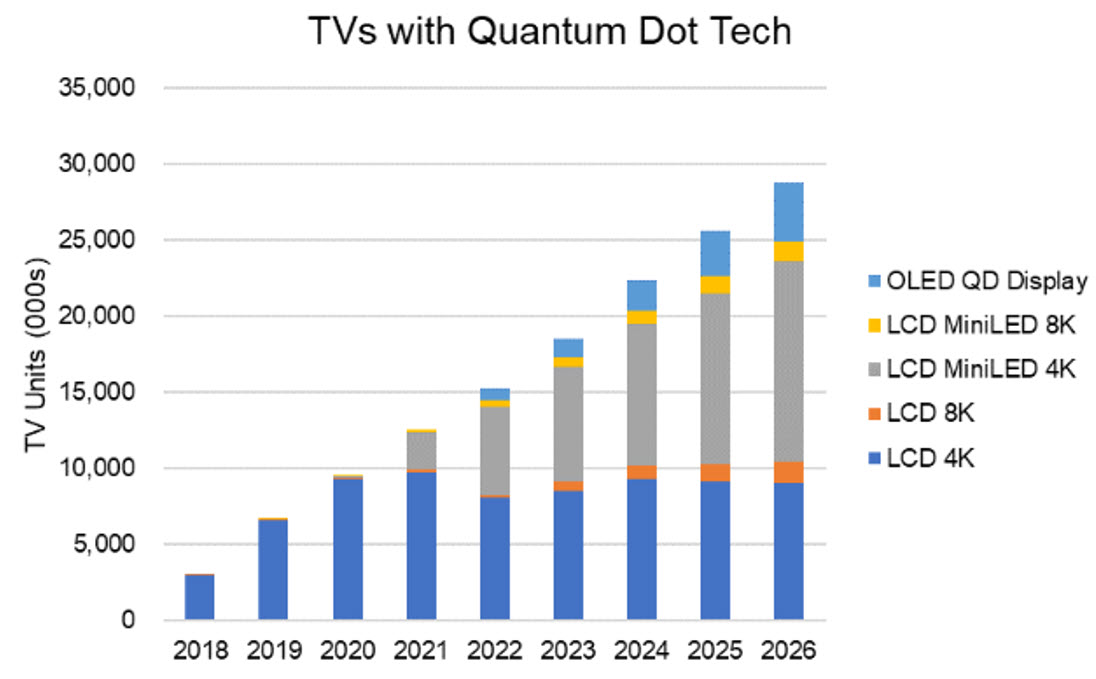

The QD-enabled TV market continues to show strong growth. I find it interesting to see QD enabled MiniLED and QD-OLED becoming significant contributors in the next few years. Not shown in this chart is any microLED penetration and microLED developments could certainly change the landscape. Source: DSCC, QD Forum 2021

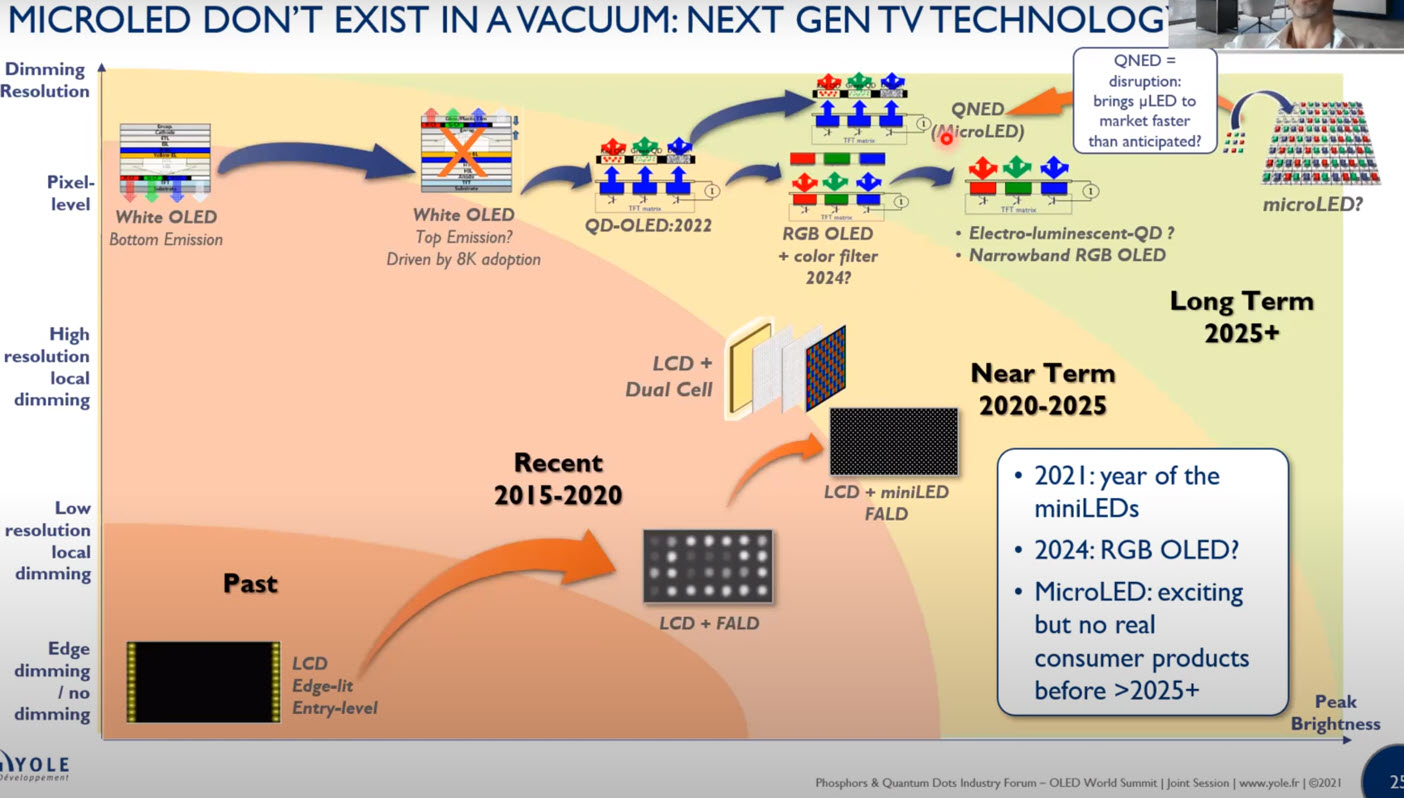

This is Yole’s vision of microLED roadmap. Notice that many of the future technologies leverage QDs to reach the market (QD-OLED, EL-QLED, QNED). It appears, based on these projections, that it will be after 2025 before we see microLEDs in the market. Source: Yole, QD Forum 2021

QD penetration since inception in 2013. The growth has been quite dramatic, especially in the past few years. Well over 200 SKUs in 2021 is pretty impressive! Source: Nanosys, QD Forum 2021

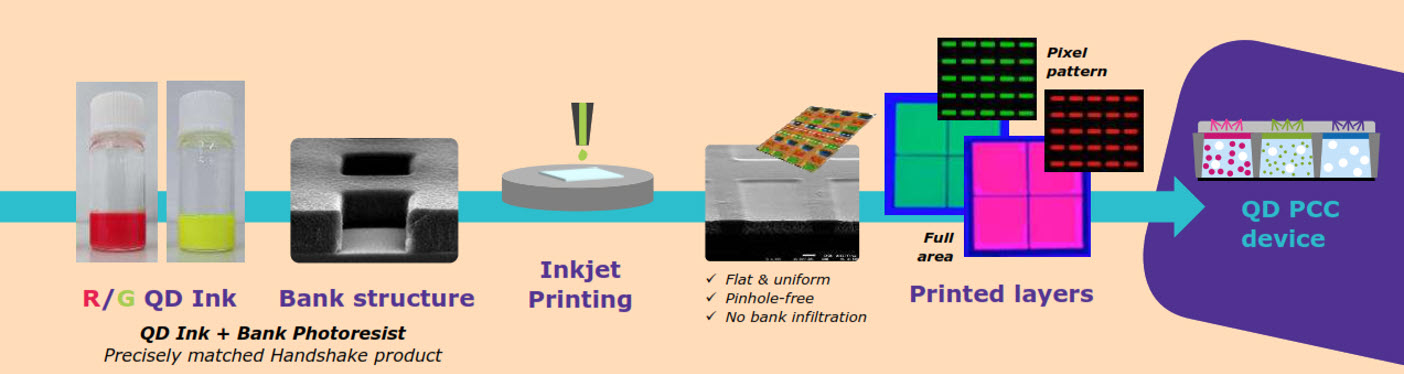

QD ink development for QD color converters will be vitally important for future QD technologies. This simplified process shows how the QD ink could be used in a QD color converted product. Source: Merck, QD Forum 2021

A diffuser plate containing QDs with mini LED backlight. Nanosys announced their partnership with CYK to make an extruded diffuser plate with QDs embedded which is designed to enable QD adoption in low cost displays. Source: Nanosys, QD Forum 2021

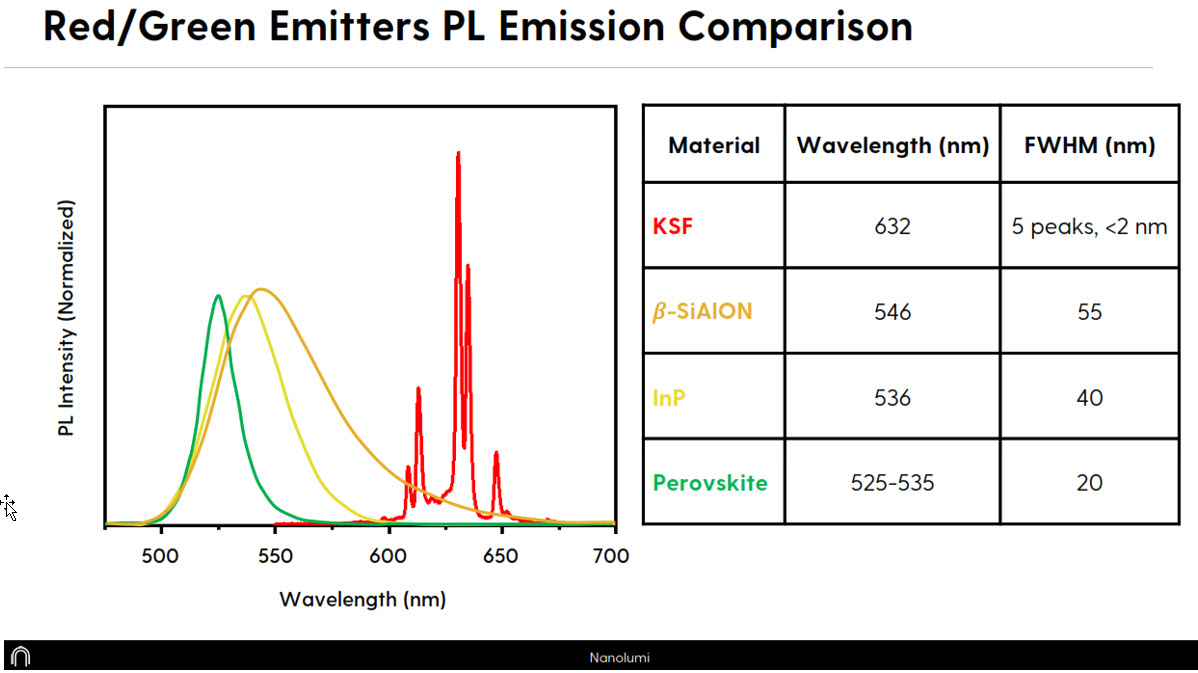

Comparison of various green emitters along with red KSF spectrum. Notice that the peak width (FWHM) is extremely narrow for perovskite. However, this is the only material listed that contains heavy metals (lead) which may be a deal-breaker for some companies. Source: Nanolumi, QD Forum 2021

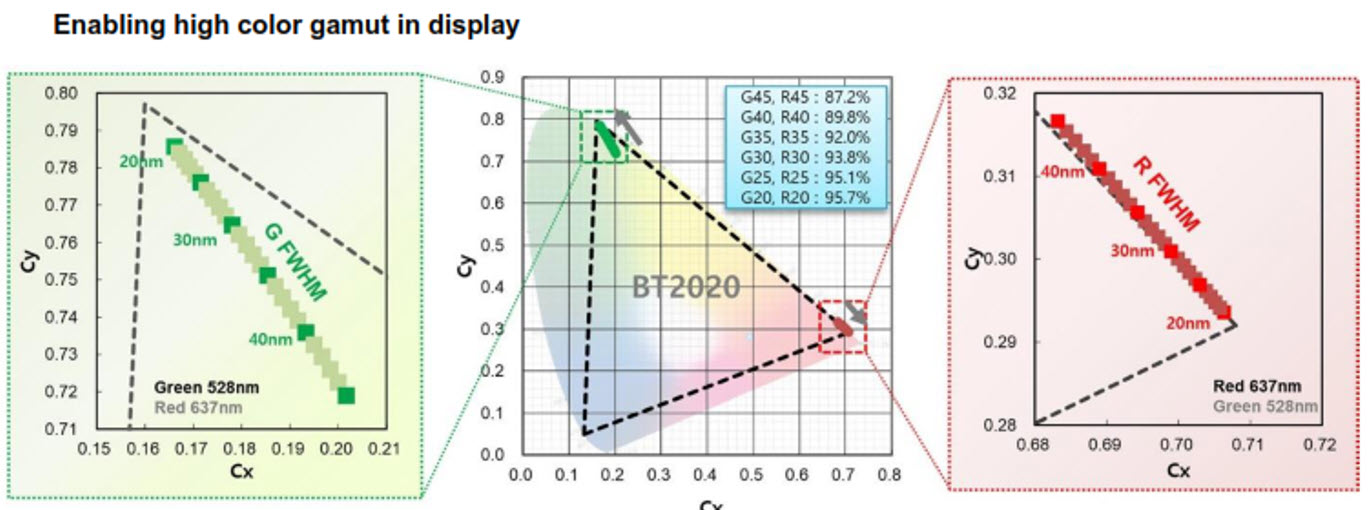

Impact of QD peak width (FWHM) on color gamut at a fixed wavelength. Notice how much more sensitive green is to FWHM compared to red. Only the narrowest of emitters will enable a fully Rec. 2020 gamut. Source: Samsung, QD Forum 2021

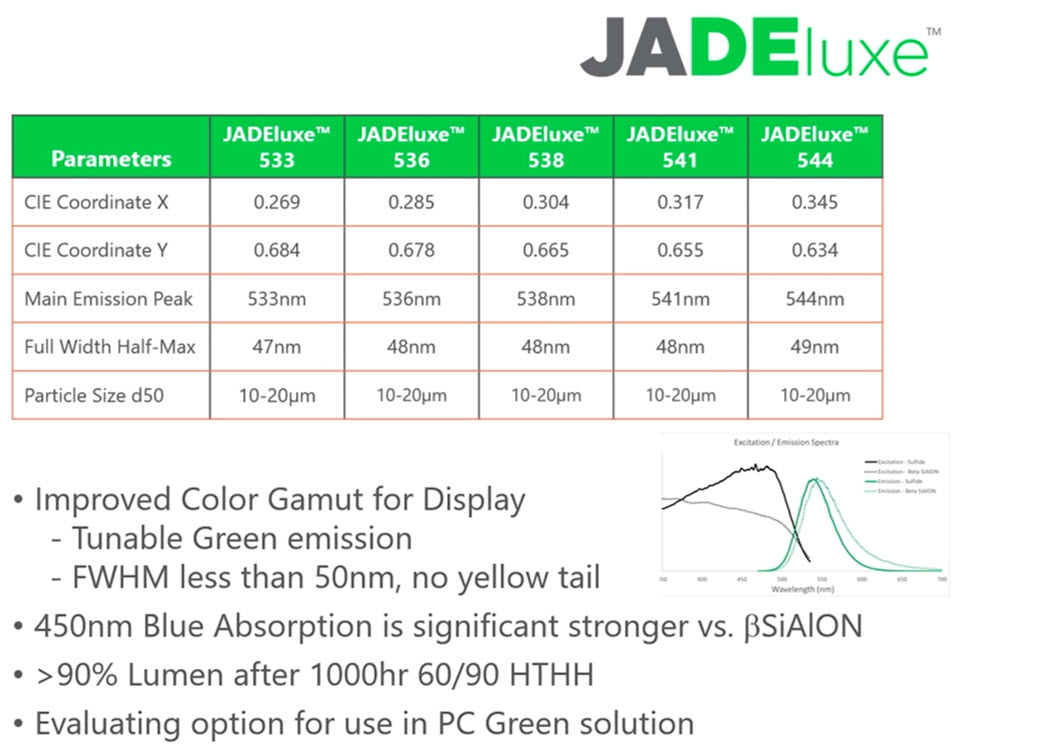

A new green phosphor in development by Current Lighting showing improved emission on chip compared to other narrow green phosphors. Interestingly, it also appears to be tunable like QDs. This green phosphor, when paired with KSF, should allow for good color gamut in a fully on-chip solution, or it could be used in a film just like QDs are used today. Source: Current Lighting Solutions, QD Forum 2021.

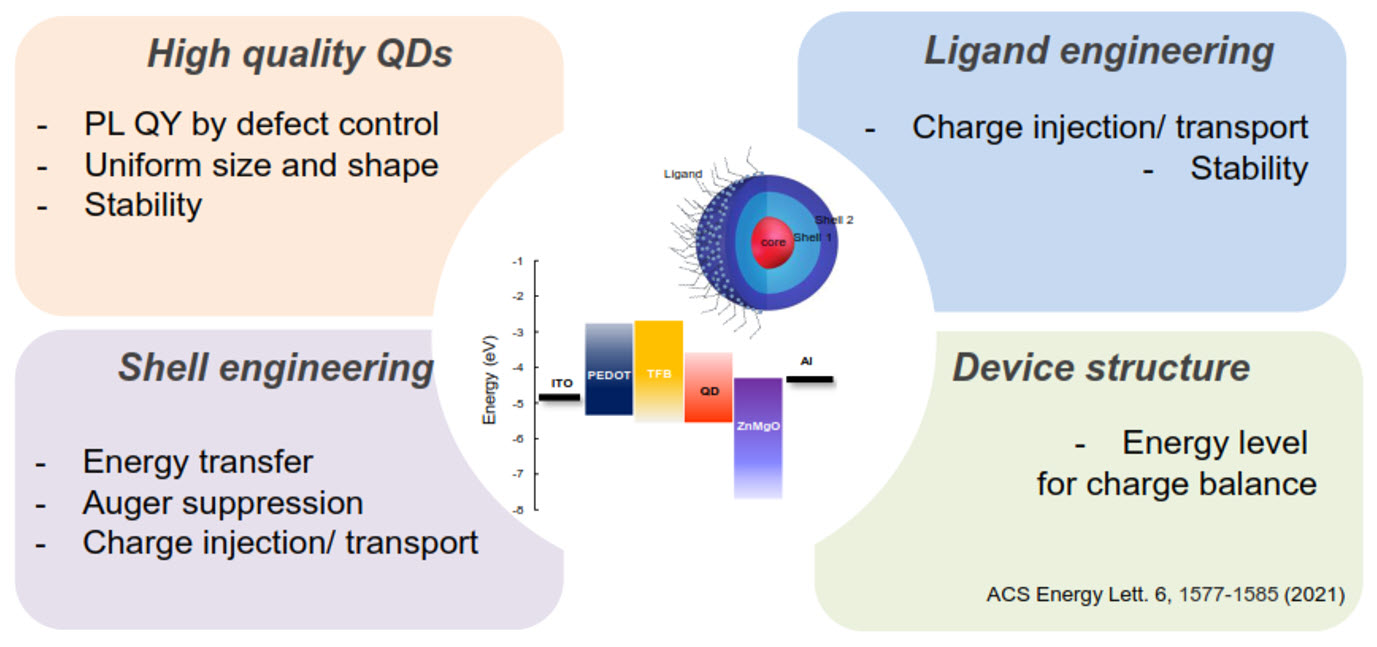

There are many challenges surrounding EL-QLED work which are interdependent. This is one of the reasons the technology is taking a long time to reach commercial readiness. Source: Samsung, QD Forum 2021

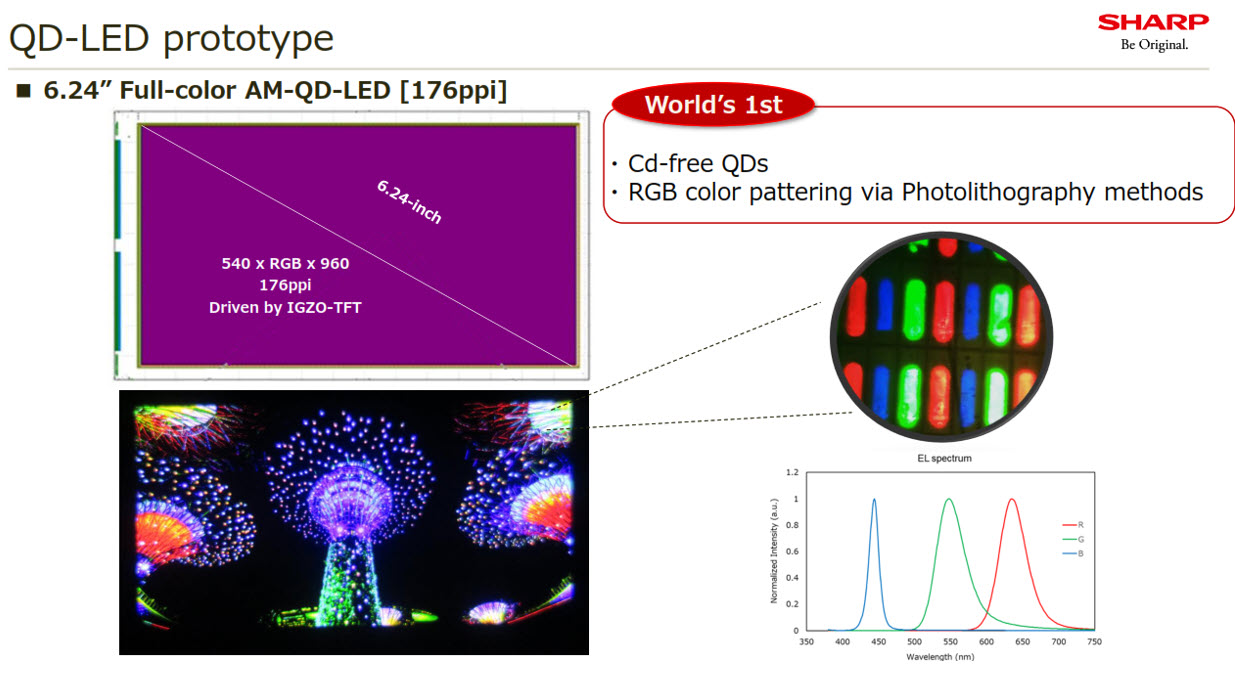

A EL-QLED device prototype produced with photolithography (not ink jet printing). This method can produce very high quality pixel patterns with uniform thickness, but may suffer from significant material loss. Source: Sharp, QD Forum 2021

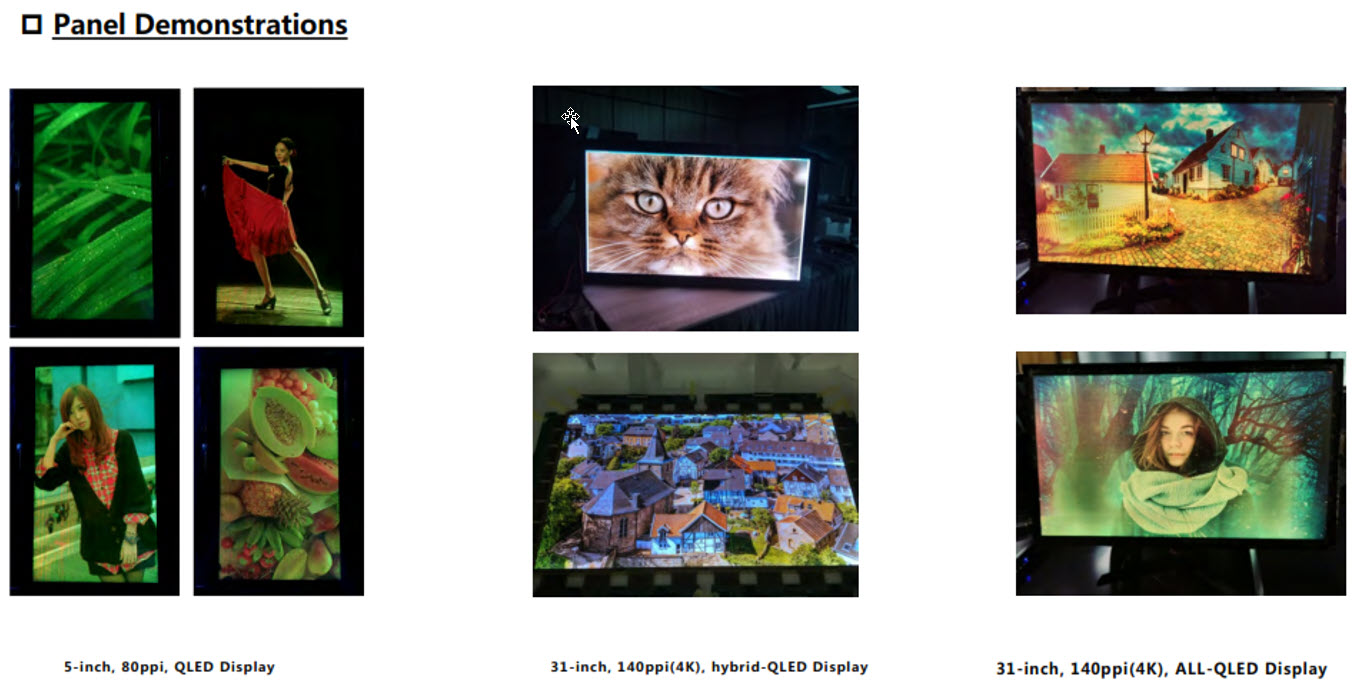

More prototypes of EL-QLED displays from the past few years. The overall dimensions and resolution continue to improve in these Cd-containing examples. Source: TCL, QD Forum 2021

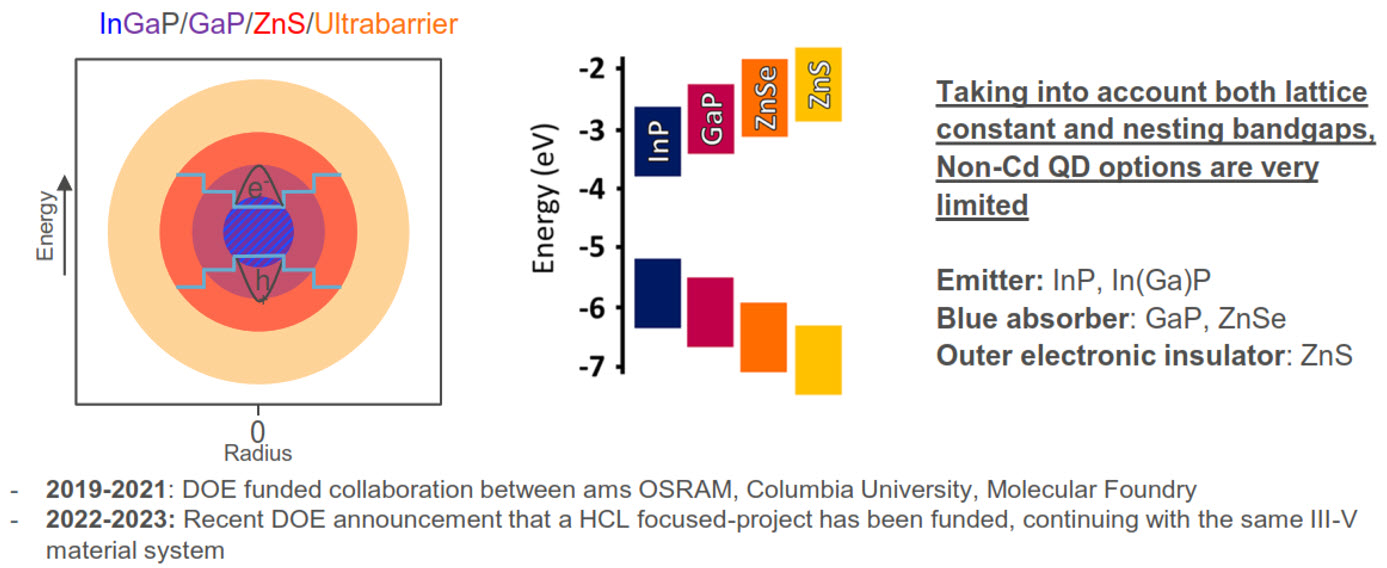

Achieving on-chip (LED) stability with non-Cd QDs is still out of reach. But it hasn’t stopped Osram from working on it with academic partners. They are actively pursuing non-Cd QD emitters for the lighting market, but I can only assume the display industry would also be interested. Source: ams Osram, QD Forum 2021

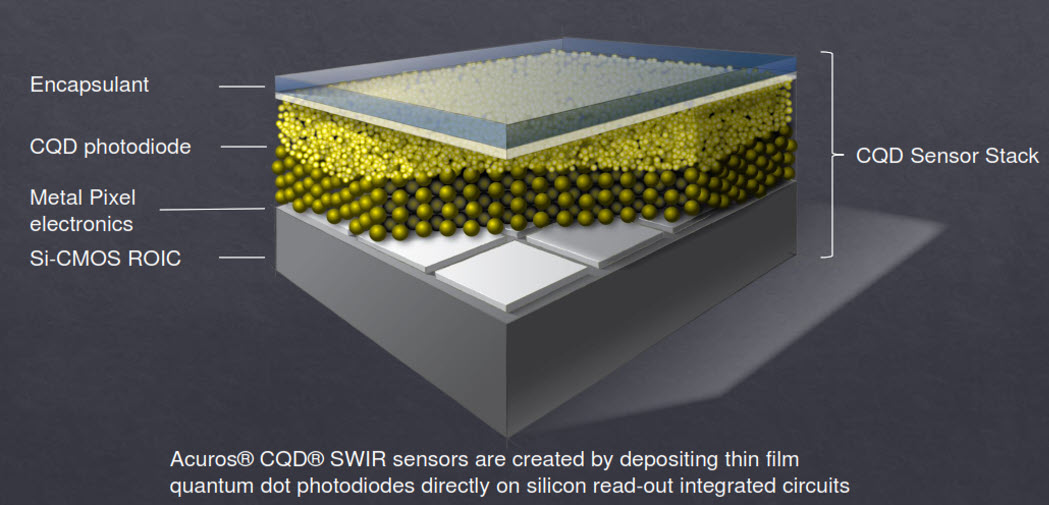

QD photodetector technology enables imaging in the infrared on a well-established Si-CMOS technology. The market for these devices is currently industrial imaging, but could soon reach cell phones and autonomous vehicles. Source: SWIR Vision Systems, QD Forum 2021

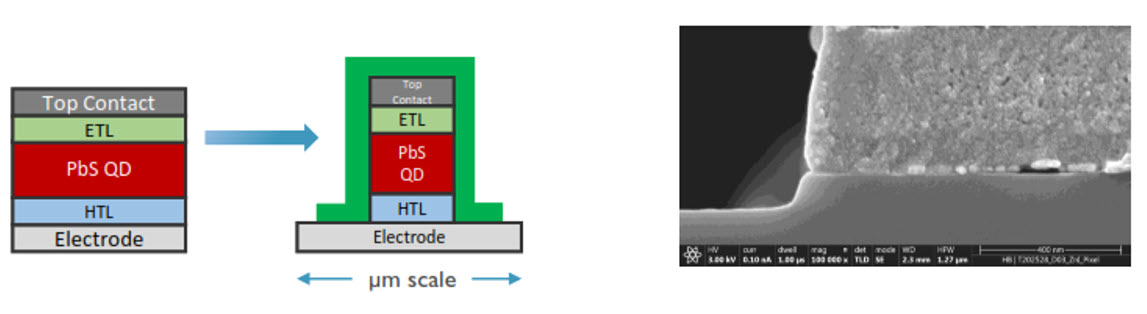

Another example of a QD photodetector. Notice how the device stack looks very similar to a QD-EL device. One major difference in the QD material used (PbS) and thickness. In the photodetector case the thickness must be sufficient to absorb as many incoming photons as possible, while in the EL-QLED case the QD layer is often only a few monolayers of QDs thick to encourage efficient operation.

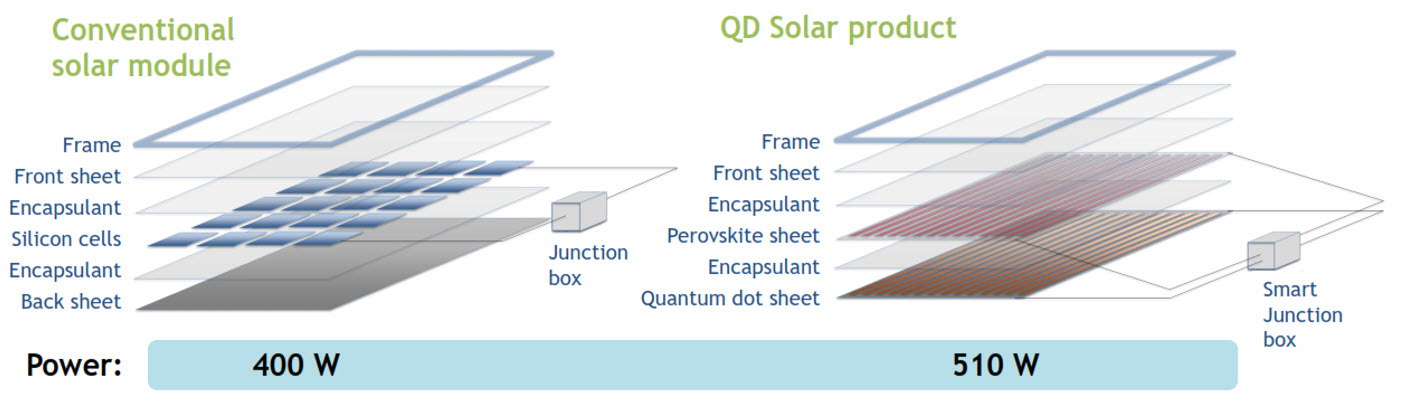

Similar technology (PbS QDs) can be used to make more efficient solar cells, especially when paired with perovskite solar cells. Source: QD Solar, QD Forum 2021

There was of course a lot more shared during the 2-day conference which was held in parallel with the Phosphor Global Summit and OLED Summit. This was only a sprinkling of what I saw this year at the QD Forum, and I hope it stimulates some interesting thoughts for you like it did for me! (PP)

Peter Palomaki is the owner and chief scientist at Palomaki Consulting, a firm specializing in helping companies solve big problems at the nanoscale. His utilizes his expertise in quantum dots and materials chemistry to solve challenging problems with clients large and small.