There were three papers in session 36 at DisplayWeek and some news from ColorLink. Overall, there was very little new information in the projection arena this year.

In session 36, our own Matthew Brennesholtz gave a very nice double-length talk that provided an overview of solid state light sources in projection. These include RGB lasers, laser phosphor, LED and hybrid sources. His talk described the many variations on the architectures that are possible in these four categories, leaving plenty of room for innovation and differentiation among suppliers.

The Green Gap

He noted that the “green gap” has been a major hurdle with few solid state sources available between 540 and 580 nm that have acceptable power outputs and efficacy. He didn’t think this gap had been filled, but the following speaker from Christie noted that Nichia now has a solid state green laser diode that is being using in theatrical projectors and is in the 1W range. You can actually buy these today for $295 each but the wavelength at 520nm is a little short for ideally covering the BT. 2020 color gamut (the green primary in BT.2020 is 532nm.)

The Philips ColorSpark High Lumen Density green solution is also now available in a Hitachi projector offering 3500 lumens – well above what other RGB LED projectors can offer. This will help create an opportunity for LED projectors in mainstream applications, but the spectral width of the green is fairly broad, so it has only achieved a color gamut of sRGB, so far. That may be suitable for many applications, however.

Cinema is the Focus

Michael Perkins from Christie focused on discussing cinema starting with some history of the digital transition and the introduction of 3D and advantages and disadvantages of various light sources.

In laser phosphor light sources, he noted that yellow-based phosphors are not very efficient as they need a yellow notch filter to create green and red components – and the red is a bit weak so a red laser diode is need for full DCI-P3 color gamut coverage. And, the physics of these phosphor wheels suggests that thermal control will limit their power outputs.

Comparing the total cost of ownership of Christie’s 8K lumen laser phosphor projector to those based on Xenon lamps, which will need up to 30 replacements during the 30K hour lifetime of the laser phosphor wheel, the laser solution is about 25% cheaper.

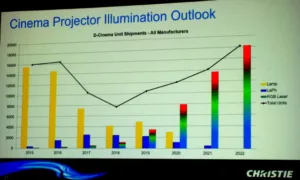

But if you move to a 19K lumen offering like one from Barco, the laser cost is 25% higher than a lamp solution over the same 30K hours. That’s why Christie thinks that laser phosphor projectors only have an advantage on smaller screens and only for a limited time, as they expect RGB laser prices to decline and expand their share over time (see forecast below). Plus, RGB laser is the only approach that can reach beyond P3 to BT.2020 color gamuts.

Perkins’ talk mainly covered ground we have reported on before but I did get a chance to ask a little more about their newer 5000:1 projectors. He said the contrast boost is mainly due to the ability to use an f/4 optical system in the projector. This has resulted from switching from a fiber-coupled solution and by moving to the Nichia green laser diodes. Plus, the cost of the fibre was very expensive, so the integrated approach should result in better performance at lower cost.

The final paper was from Sony and focused on improvements in light extraction efficiency from phosphors used in projectors. Improved efficiency will help with higher brightness, lower power, smaller form factors and lower fan noise.

Previously, Sony’s efforts focused on improving the phosphor wheel structure and cooling system to gain an improvement on phosphor light conversion efficiency. In the current effort, they focused the extraction efficiency of the phosphor light.

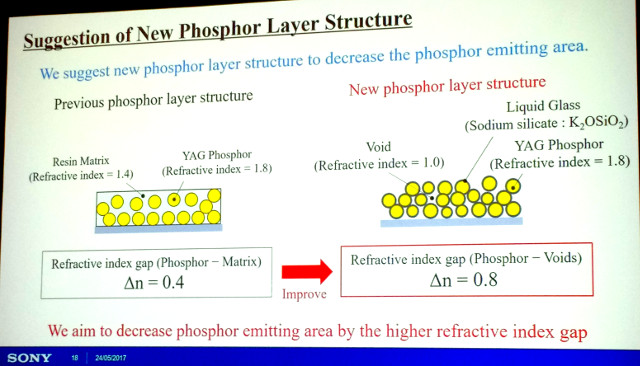

The extraction efficiency is an étendue problem. The smaller the emitting area, the more light can be collected, but the efficiency may go down due to thermal quenching. Sony developed a model for this extraction efficiency, but the measured results did not match the model. This turned out to be due to light traveling horizontally in the phosphor wheel by total internal reflection before being extracted. The result was an emitting area that was bigger than the illumination spot.

It turned out that the difference in the refractive index of the YAG phosphor and the binder matrix was the driving factor, so they changed the binder matrix to increase the refractive index difference from 0.4 to 0.8. The new formulation is called liquid glass. This reduces the emitting area and resulted in a 10% improvement in extraction efficiency. – CC