In a collaborative effort, Germany’s Plan Optik and 4JET have developed a cutting-edge process chain for the high-speed production of metallized through-glass vias (TGV) using what they call volume laser induced structuring (VLIS) technology. This approach streamlines the manufacturing of precision TGVs in glass wafers or substrates for advanced packaging and displays, including MicroLED-based screens.

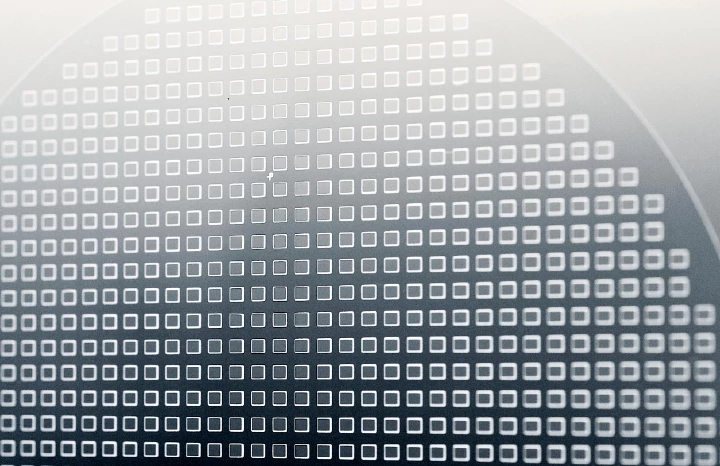

TGVs are micro-holes ranging from 10µm to 100µm in diameter, employed in advanced packaging applications and display manufacturing. Traditional methods for creating TGVs were slow, yielded high reject rates, and posed challenges in the metallization process. The new VLIS process, however, can generate tens of thousands of vias per minute, etching them in a batch process before subsequent plating. The resulting channels have hole-to-hole accuracy better than +/- 2µm, exhibit no microcracks, and feature smooth-walled insides, enabling homogeneous metallization. This process is compatible with typical glass types used in the semiconductor and display industries.

Plan Optik and 4JET’s partnership offers flexibility to customers who can either purchase VLIS-produced components from Plan Optik or acquire qualified total solutions, including laser systems, wet chemistry, and metallization from 4JET and partners.

This cooperation advances the state of the art for TGV production by merging Plan Optik’s extensive process chain with 4JET’s system technology. The PEARL platform, a modified version of 4JET’s glass-cutting laser systems, is capable of high-precision modifications on large substrates, opening up new applications in display manufacturing.

The VLIS process also holds potential for glass-based MEMS, microfluidics, and high-frequency antenna technology. The PEARL systems utilize a granite machine platform that ensures accuracy and long-term stability, with the ability to import cutting geometries and positions from CAD drawings. The system maintains focus within the process window without increasing processing time.

Plan Optik is known for its technology to produce structured wafers for microsystem technology applications across various industries, while 4JET delivers surface technology solutions for a wide range of applications.