Quantum dots (QDs) would seem to be an excellent candidate for use as a color conversion layer (CCL) in MircoLED-based displays. One reason for this potential is that QDs can produce a wide color gamut as compared to conventional fluorescent phosphors. There are, however, difficulties in using QDs in the CCL application. Part of the problem relates to surface defects that can occur in QDs. Such defects originate from the “thick shelling” needed to maintain their desirable optical properties. More specifically, the problem relates to the fact that achieving a thick shell requires extra and complex processing steps during the synthesis of the QDs. An additional problem with QDs is the fact that, in order to achieve an efficient CCL, the CCL needs to absorb light as thoroughly as possible. Efficient absorption requires a physically thick CCL. Unfortunately, producing a layer that is sufficiently thick can be challenging. It is certainly difficult using spin coating. There are also difficulties using ink jet printing and vacuum drying. In the latter two cases, interlayer defects or surface uniformity problems often occur due to the repeated processes needed to build up a thick layer.

Due to the raft of problems associated with QDs, researchers have investigated alternative approaches to producing a CCL. One promising approach is based on the use of perovskite quantum dots (PQDs). This class of materials is more defect tolerant than conventional QDs. Unfortunately…. PQDs have their own set of problems.

PQDs are very sensitive to contamination by atmospheric oxygen and moisture. The conventional approach to improving the atmospheric stability of PQDs is the use of polymer encapsulation. Unfortunately, it has been found that there is a dispersibility issue associated with the use of polymer encapsulation and that this, in turn, may decrease the photoluminescent efficiency of PQDs. Moreover, polar organic solvents commonly used to disperse the polymer can potentially cause the decomposition of PQDs.

Addressing the difficulties associated with the use of PQDs in the CCL application was the subject of the investigation conducted by a team of researchers headed by Hyung Cheoul Shim with the Department of Nano-Mechanics, Korea Institute of Machinery and Materials (Daejeon, Republic of Korea). The approach adopted by the researchers to fabricate PQD CCLs that have sufficient thickness and that can be easily photopatterned is described as a “squeezing technique.” A recent article on this topic by the team is entitled “Full‑color micro‑LED display with photo‑patternable and highly ambient‑stable perovskite quantum dot/siloxane composite as color conversion layers.” It was published in Scientific Reports 13, 4836 (2023).

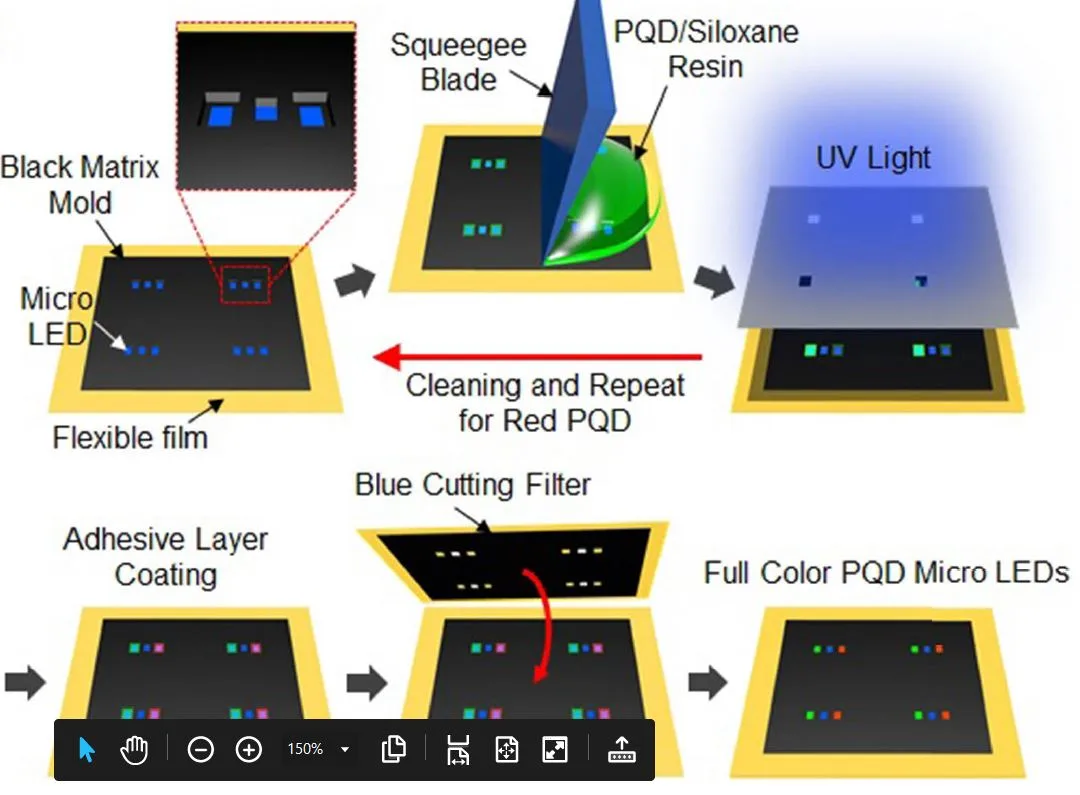

The graphic below illustrates the process developed by the researchers for fabricating full color MicroLEDs incorporating PQD-based color conversion layers.

Paraphrasing their article, the main features of the process developed by the researchers are as follows. The PQD surface was activated using anion salt and then arranged in a silane ligand. Doing so enables the preparation of PQD/siloxane composites without aggregation and degradation of the PQDs. That is, dispersibility was accomplished without damage to the PQD.

Some results of measurements made on prototype devices fabricated as part of the study and using the new technique are as follows. The quantum yields of green and red PQD/siloxane composites in film form reached 89% and 55%, respectively. The FWHMs were around 22.7 nm and 39.8 nm. Using these materials and processes, a full-color MicroLED display with a resolution of about 25.4 PPI on a 1-mm pixel pitch was successfully fabricated. In addition, it was possible to fabricate full color CCLs for MicroLED with excellent atmospheric stability that maintains 80% of the original photoluminescent efficiency even after 1 month.

The researchers go on to report that they applied their new technique to a very flexible printed circuit board substrate on which there was a thin black matrix such as typically used to prevent blue light interference. With this prototype, the researchers demonstrated that it was possible to produce a flexible full color MicroLED that can operate without any problem even with a bending radius of 5 mm.

The researchers conclude their article with the statement that “These composite materials have superior atmospheric stability compared with PQD CCLs prepared via conventional ink jet or vacuum drying processes and can be manufactured to a sufficient thickness to achieve high light conversion efficiency and photo-patterning properties.”