A team of researchers headed by Xiu Liu of the School of Optics and Photonics, Beijing Institute of Technology (Beijing, China) is developing perovskite-based quantum dot microarrays that offer great potential for Quantum Dot Color Conversion (QDCC).

In display applications, an approach based on QDCC could be used to replace conventional absorptive RGB colored filters. In such a display, a QDCC-based layer composed of red and green quantum dots would be patterned at the subpixel level. Such a layer could, in principle, be easily integrated into the mechanical structure of current technology LCDs. The function of the layer would be to absorb incoming light produced by a blue light emitting backlight and re-emit high purity red and green light. As there are no blue quantum dots at present, blue light emitted by the backlight would simply be transmitted by the QDCC layer without modification. One important benefit of this approach could be greater display energy efficiency. This would be due to the fact that the QDCC-based approach has the potential to produce useable light more efficiently than one based on absorptive colored filters.

Unfortunately, despite great potential, there remain unresolved problems that hamper the use of QDCC ‘filters’ in display applications. One significant problem is that QDCC pixels are typically fabricated using inkjet printing. It is found that QDCC pixels fabricated by this means are too thin to achieve efficient color conversion. In addition, ink jet related “coffee ring” effects tend to occur and this lowers light conversion efficiency and emission uniformity. (A “coffee ring” is the pattern that can be left by a puddle of a particle laden liquid after the puddle evaporates.) These problems also contribute to blue light leakage and optical crosstalk.

One approach with potential to solve these outstanding QDCC problems is the use of perovskite quantum dots. This approach uses patterned black photoresist molds as part of the process used to fabricate the quantum dot pixels. On the up side, previous work investigating this approach demonstrated that it was possible to increase pixel thickness and avoid the optical crosstalk. Unfortunately, implementing this approach was found to substantially increase manufacturing cost. To address this issue, the current research team set out to develop a method to cost effectively fabricate perovskite quantum dots with “a robust 3D structure.”

A recent article by the researchers on this topic was entitled “Perovskite quantum dot microarrays: In situ fabrication via direct print photopolymerization.” It was published in Nano Research. The article is available for purchase on-line and can be found here.

The approach adopted by the team was based on fabricating 3D perovskite quantum dots microarrays by combining inkjet printing with the in-situ fabrication of perovskite quantum dots during the photopolymerization of precursor ink. The idea was that the in-situ direct print photopolymerization technique would allow for precise control of the pixel structure and remove quantum dot aggregation and coffee ring effects from the microarray.

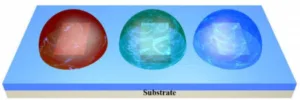

The technical article provides detailed information on the materials and fabrication processes used to produce prototypes. In addition, details on the means by which the prototypes were evaluated and the results of measurements made on the prototypes are also contained in the article. The bottom line is that, using this technique, the team was able to produce a patterned, high resolution, multicolor perovskite QDCC microarray with a pixel size of 20 microns. The quantum dots had a hemispherical shape and were photoluminescent over a large area, all characteristics desirable for the application of QDCCs in displays. A graphic of the microarray is illustrated in the figure below.

Quantum dot color conversion microarray.

The researchers concluded their article with the statement that “they are confident that this technique paves the way for the further fabrication of full color QDCC micro-LED displays.” –Arthur Berman