I reported on a talk by materials technology start-up, OTI Lumionics after the Business Conference during Display Week last year and this week I had the chance to catch up with CEO Michael Helander on a Zoom call. The ostensible topic was the developments of the company’s materials which can be used to improve the cathodes in OLEDs.

This may seem to be a bit of an arcane piece of technology, but it turns out to be quite important. As I outlined in my article last year (Materials Remain Important for Under-Display Cameras), the prime benefits of the self-patterning materials are:

This may seem to be a bit of an arcane piece of technology, but it turns out to be quite important. As I outlined in my article last year (Materials Remain Important for Under-Display Cameras), the prime benefits of the self-patterning materials are:

- Potential to pattern cathodes to

- make cameras under the display better avoiding the notch

- improve the performance of other sensors (e.g. fingerprints)

- particularly help the transmission of infrared for Face ID

- the possibility of optimising the cathodes for the different coloured material to boost efficiency and brightness

- the cathodes can have lower resistance to make foldable devices better and less difficult to make

That’s a compelling list of possible improvements. I often here these kinds of claim, but don’t have the resources or expertise to dig into this kind of claim. However, the company reported that LG Ventures had invested in the firm (OTI Lumionics Announces Strategic Investment from LG Technology Ventures). That gives me a bit of reassurance. Big companies investing doesn’t always convince me (pace Magic Leap!) but where there is tricky technology, investment from firms in the same area that have the resources and technology to check things out is comforting. I haven’t seen an overt scam in recent years, but I have seen a few over the years!

A challenge at the moment for start-ups in the West (OTI is based in Canada) with clients in Asia is that Covid has made customer support much harder. Fortunately, Helander told us, OTI had already got the attention of potentical customers and has had its own in-house pilot line, so is better able to support the introduction of its materials into production. However, there have been challenges in the firm’s supply chains with delays and costs. He also commented that he has high value materials, so in the past, shipping costs were relatively small, but have increased so much that they might start to influence pricing.

The eventual customers for the displays with OTI materials are smartphone makers and we talked about the withdrawal of LG from the smartphone market. I mentioned that research shows that LG was #3 in the US market and it is rare for CE firms with such a good market ranking to simply give up. Usually, even if there are problems, others might want to take over the business. However Helander believes that increasing commoditisation of the smartphone market makes differentiation harder and harder. As a result, to develop a smartphone that is really ‘different’ in any way demands huge resources. Without a big share, you just don’t have the resources. LG was strong in the US, he pointed out, but at the low end of the market.

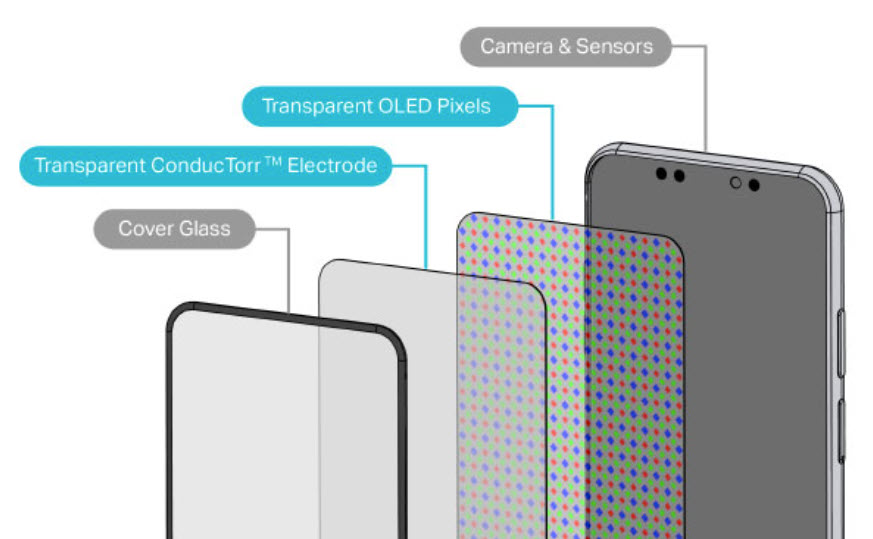

A big topic at the moment in smartphone OLEDs is the elimination of polarisers from flexible displays. Samsung is reported to have developed POL-LESS OLEDs, also known as Color-on-Encapsulation (COE). A bit of background might help here.

Very simply, polarisers are put on the front of OLEDs because they improve the contrast in conditions where there is significant ambient light. If you put a polariser on the front of the display, ambient light is reduced by (roughly) half on the way in and on the way out, so it’s down to less than a quarter of the original light. The light from the display is also reduced but only by around half, so, at least, you double the contrast.

The polariser layer is thicker than OLED makers would like (see Barry Young’s article for more on this (Samsung’s Z Fold 3 Thinning Innovations Could Make All Flexible OLEDs Brighter)).

Helander told us that this work has been going on for four or five years as panel makers tried to improve the performance of foldable devices. One of the challenges has been that you need low temperature processes to avoid damaging the OLED materials.

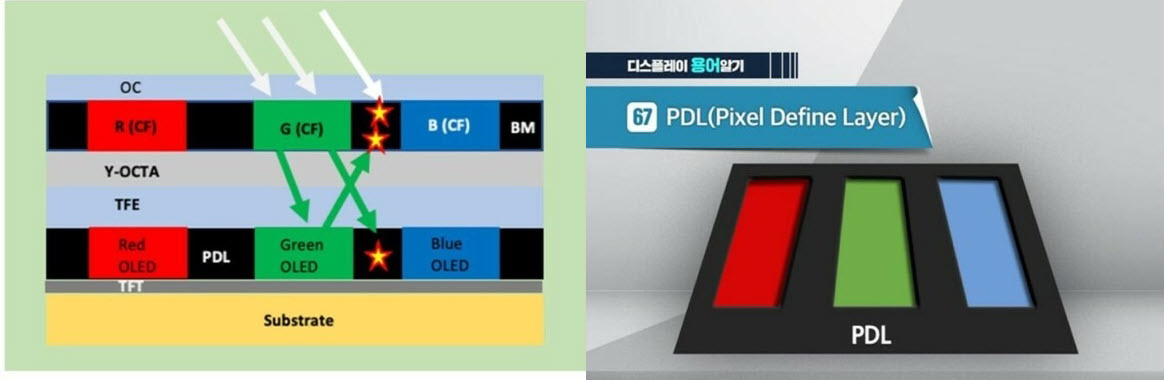

If you look at OLEDs, most of the surface is not the OLED material itself, it’s the pixel defining layer (PDL) which is a black area between the pixels. The layer is important in absorbing the light coming through the polariser. The more absorbent it is, the better the contrast. It turns out that OTI’s materials can be used to create these layers as well as the cathodes.

Samsung Display’s POL-LESS AMOLED Structure and PDL Source: DSCC, ETNews

Samsung Display’s POL-LESS AMOLED Structure and PDL Source: DSCC, ETNews

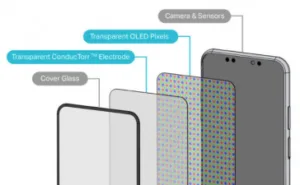

Switching from a polariser to colour filters to reduce ambient also means that the polariser no longer blocks the light to a camera or to a sensor such as Face ID.

Of course, making this kind of colour filter is not trivial and means more processing and capital equipment compared to just buying polariser film.

Foldable phones are not the only application. Supposing you could use a similar approach to make it easier to roll up large OLEDs for TV applications? If you could roll up OLED TVs more tightly, you could make the box out of which the TV unrolled smaller, which would make the technology even more attractive. (BR)