Germany-based Osram Opto Semiconductors is a leading manufacturer of LEDs, as well as other opto-electronic devices. In a recently released interview with Yole Développement display analysts Eric Virey and Zine Bouhamri, Matthias Winter, Senior Director of Strategic Programs at Osram OS, said “We’re convinced that microLEDs will play a major role in various applicative fields. “

It is not surprising that a leading LED developer and manufacturer would be interested in exploring the path from macro to micro. Winter added some details, in what sounds like a very carefully prepared statement:

“With its many years of experience in the field of optoelectronics, Osram OS is about to play a leading role in the development and manufacturing of microLEDs in the future. Our teams have the needed know-how and specific expertise in complex but essential LED manufacturing processes like epitaxy, light extraction and transfer technology. Our expertise in LED manufacturing, which has been built up over decades, combined with our unique manufacturing infrastructure for all three primary colors, [gives us a significant advantage].”

Last year, Osram OS acquired Pacific Light Technologies (Portland, Oregon), as reported in Display Daily (Osram Acquires Pacific Light Technologies). PLT has been developing quantum dots that can be deposited directly on LEDs, which is difficult because quantum dots do not take well to high luminous flux and high temperatures. Osram OS’s motivation in acquiring PLT is clear. It is generally easier to create an all-blue array of µLEDs and use quantum dots to convert the blue to green and red than it is to create an array of red, green, and blue (RGB) µLED chips. Based on statements by the company, Osram OS felt this quantum-dot knowledge was expertise it needed to buy.

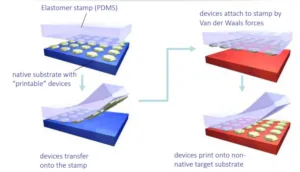

But there are applications where RGB chips are the indicated approach. So, also last year, Osram OS licensed X-Celeprint’s miro-transfer printing (µTP) technology (Fig. 1), (OSRAM Opto Semiconductors, X-Celeprint Enter into License Agreement Covering Micro Transfer Printing) which permits selected µLED chips to be removed for their native epitaxial wafter and deposited on a display substrate with an expanded pixel pitch.

Fig. 1. The micro-transfer-printing process for moving µLED chips from their native epitaxial wafers to a display substrate looks simple here, but doing it a very high speed and with very high reliability is challenging. (Graphic: X-Celeprint)

Put these two agreements together, and it seems Osram OS is investigating the production of sub-systems or even systems rather than just devices. This would make perfect sense. As the purveying of devices, be they display panels or LED chips, becomes more and more cut-throat, companies that have the capability can be expected to incorporate their devices into subsystems or systems that bring them closer to their customers and provide their customers with greater differentiated value. In an interview I had recently with Dongsheng Wang, Founder of BOE, he detailed just this approach and said, “If all goes well, you will not recognize BOE in ten years.” (For the complete interview, see the November/December issue of Information Display Magazine.)

Although the general approach of making µLEDs, transferring them to a substrate with µTP, and driving them either with a TFT backplane or by using µTP to transfer CMOS driving chips to the substrate understood, the challenges of doing it at high volumes with very high speed and very high reliability are considerable. Winter said it “would take some years” before µLEDs are produced in high volumes. (KW)

Ken Werner is Principal of Nutmeg Consultants, specializing in the display industry, manufacturing, technology, and applications, including mobile devices, automotive, and television. He consults for attorneys, investment analysts, and companies re-positioning themselves within the display industry or using displays in their products. He is the 2017 recipient of the Society for Information Display’s Lewis and Beatrice Winner Award. You can reach him at [email protected] or www.nutmegconsultants.com.