We have had a couple of interesting news announcements from Osram in recent weeks. The first was a new LED that was announced a couple of weeks ago that puts a red phosphor layer and a QD-based layer to produce green into a white LED for the first time. The company has kept its cards very close to its chest on this development, turning down interview requests and only answering questions that have been submitted in writing. At CES, in its Westgate suite, it didn’t want to talk about these LEDs to us at all. (Osram Offers LEDs with QD Boost (Updated 3/12/15))

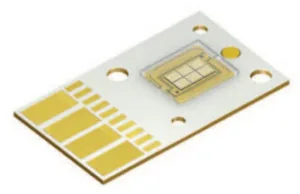

The second development was of new red, green and blue LEDs for projector light sources that can take the brightness of LED-based projectors up into the mainstream region of 2,000 ANSI lumens or more. The P1 used two, the P2 four and now the new P3W LED uses 6 chips in an array. One of the key developments has been the engineering needed to put the P3W onto a PCB of the same size as the P2, so that projector makers will find integration easier.

The big change that has enabled the new LED, in addition to an improvement in LED efficiency, has been a new solder system that puts metal films on the base of the LED and the PCB. The devices are brought together and infrared is used to melt the surfaces to create an optimised “intermetal” contact layer that is thinner than traditional solders. That reduces the resistance to the propogation of heat from the LED chips.

To get efficient optical efficacy, it’s important to match the light source to the correct size of imager, so some optical changes may be needed by projector makers.

Osram said that its chip is sampling now and will be available from March, so it expects to see new projectors using the LED at Infocomm.

Analyst Comment

Osram said that it is confident that the availability of this kind of new LED will mean that projectors up to 2,000 ANSI lumens will be dominated by LED and the new chips could support projectors up to 3,500 lumens. Lamp-based products are still likely to survive at the low end, partly because lamp makers will still have a small market for replacement lamps, so the volumes won’t collapse as fast as they did for the CCFL makers when they started to be replaced by LEDs. Above 2,000, laser phosphor and hybrid solutions may be a good option. (BR)