So much of being a successful start-up or technology developer is timing. Start too early and you may run out of momentum and money. Start too late and you run the risk of missing the market. This week we spoke to a microLED company that hopes it has ‘caught the wave’.

Optovate Ltd, based in Oxfordshire, UK developed some technology for microLEDs a while ago and developed technology which was patented from 2008 onwards, but the technologists behind the ideas decided that the market wasn’t quite ready. However, now the company has come out of ‘stealth mode’ and is looking for partners to commercialise its technology. In the meantime, the company has been busy with other optical technology.

The founders worked for Sharp Research in Oxford and founded Ocuity, a technology company that developed microlens technology for 3D and that we first reported on in our newsletter back in 2003, when it appeared at MWC with switchable lenticular 2D to 3D technology that was eventually sold to AUO (we reported on that technology’s appearance at FPD International in November 2010). They have recently been working developing special backlight technology for another company.

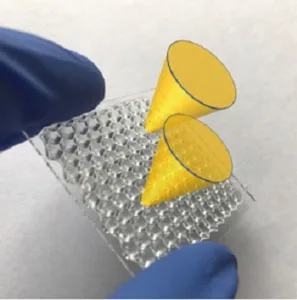

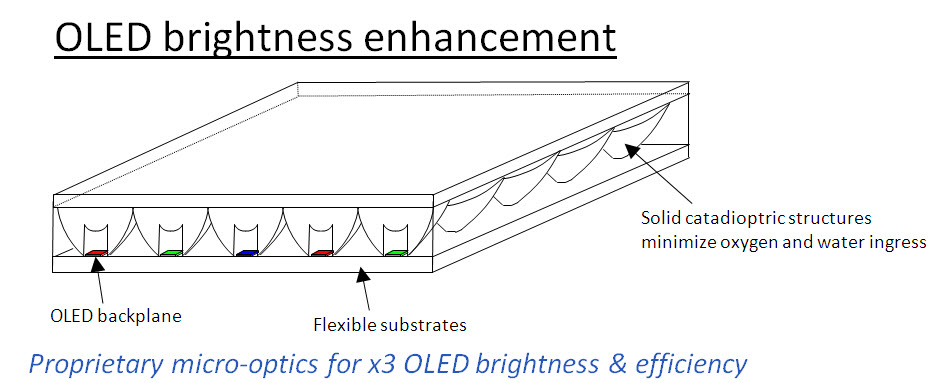

There are two core technology areas that are now of interest in MicroLED. The first is a special optical technology described as ‘catadioptric’ optics (combining reflective [mirror] and refractive [lens] effects).

The Optovate micro-catadioptric element. Image:Optovate

The Optovate micro-catadioptric element. Image:Optovate

The system of micro-catadioptric elements are used for two purposes (the company plans to give a paper at SID that will explain more detail than this). First, the optical system can be used to optimise the light extraction from LEDs and OLEDs. One of the challenges of emissive displays is that they usually emit in many directions, when you typically want the light to be emitted in a more controlled direction, so a lot of effort is put into getting the light to be emitted in the direction you want.

Clearly, improving the efficiency of the emission of OLEDs is an important topic and the company claims a 3X boost in efficiency.

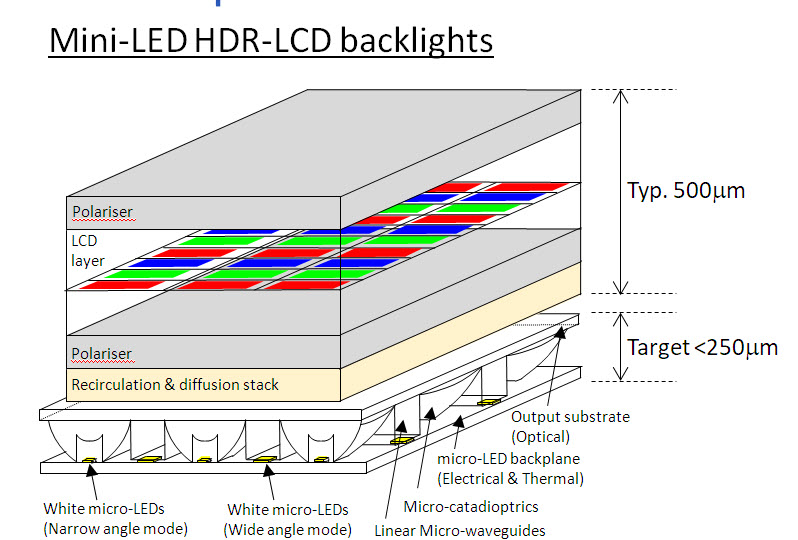

The optical system can also be used to solve a particular challenge for LCD backlights. While the industry would like to move (and is moving) to full array local dimming (FALD) to allow the creation of HDR displays and get closer to deep blacks of OLED, the challenge is that this typically increases the depth of the backlight, reducing the slimness of the LCD and weakening its competitive position compared to OLED. By using mini-LEDs and the micro-catadioptric elements, the backlight can be made very slim, but maintain the tight control. Optovate is targeting a thickness of less than 250 ?m for the LED and optic layer.

In this miniLED HDR BLU, selecting the narrow angle LEDs gives directionality to boost on-axis brightness and give some privacy. Image:Optovate

In this miniLED HDR BLU, selecting the narrow angle LEDs gives directionality to boost on-axis brightness and give some privacy. Image:Optovate

Furthermore, by using a mixture of wide angle LEDs that are not optically controlled and narrow LEDs that are passed through the lenses, the company can make LCDs that can run in a ‘privacy mode’ where the light from the LEDs is directed to come out of the LCD at right angles, which can boost on-axis brightness as well as meaning that viewers looking from the side cannot read the screen. As well as giving privacy, the low light spill might be popular for night time use.

The ability to control the direction of the output light means that there are also potential applications in AR/VR where you really want to optimise the brightness efficiency and you know where the viewer’s eye is. The applications include HUDs as well as HMDs.

There are also applications in lighting as well as displays.

Paul May, the Commercial Director at Optovate, told us that 3D printing has been a big help to the company in developing prototype microoptics for development and testing without the big committment needed to create expensive mass production tooling.

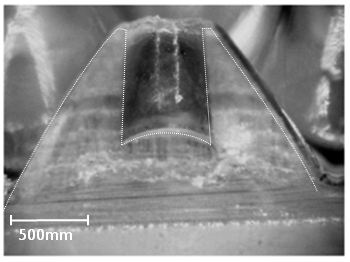

The second block of patents cover the use of laser lift off to extract microLED elements which the company has been doing for some time, but did not seem to be interesting when the company was first granted its patents. Once the microLED is placed, it can be fitted with a micro-optics array, which generates a high fill factor when the LED is illuminated.

May told us that the company will be at SID to present the paper, but also wants to set up meetings to talk to companies that might want to exploit the technology.

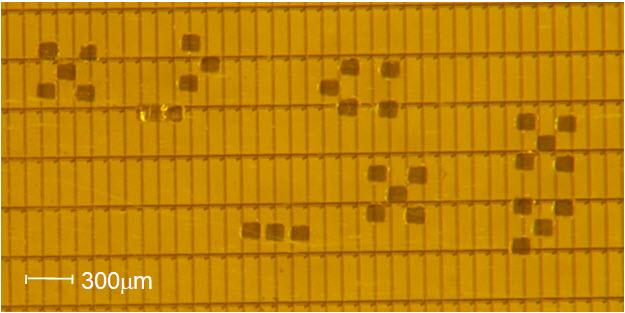

Excimer laser selectively removed multiple 100×100?m patches of a GaN on sapphire micro-LEDs mapped onto a TFT backplane as a size reference

Excimer laser selectively removed multiple 100×100?m patches of a GaN on sapphire micro-LEDs mapped onto a TFT backplane as a size reference