Wammes and Partners develop a new method to test the quality of UV-cured Optical Bondings without destroying them. Examining the quality of the optical bonding directly after the bonding process offers the chance to quickly identify problems and make improvements or rework if necessary.

This is made possible by the use of the so-called pattern approach, which is supported by powerful mathematical algorithms. This is because the special evaluation of the measurement of optically clear structures results in only a poor signal-to-noise ratio due to the principle involved. With such noisy signals, it is very difficult to evaluate a signal according to its amplitude and to find a stable pattern. The pattern approach provides very easy-to-understand RAW data from which powerful computing filters out the relevant information from the noise.

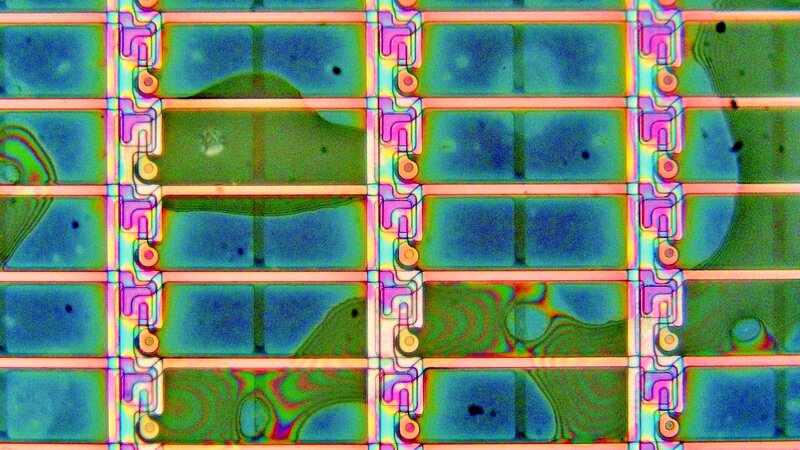

In the case of incorrect UV bonding, local wetting can become increasingly poor over the course of the (application) time – and undesirable, clearly visible and thus disruptive artifacts can develop. The non-destructive analysis shows this clearly.

In the case of incorrect UV bonding, local wetting can become increasingly poor over the course of the (application) time – and undesirable, clearly visible and thus disruptive artifacts can develop. The non-destructive analysis shows this clearly.

The non-destructive analysis strictly focuses on the adhesive layer including the interfaces and provides a wide range of high-resolution details, both in microscopic and macroscopic applications. The very high reliability of the results has been proven so far on more than 2000 different problem cases from the field. In addition, the new analysis can also be used for very many other bonding problems than just UV resin-based bonds.

“Up to now, a subsequent analysis of the quality of the optical bonding of a given display was rather pointless, as it was either not very informative or destroyed the display when examined closely. Using a new method, semi-finished products and devices can now be analyzed for their bonding without destroying them, delaminating them or affecting the integrated display,” explains Klaus Wammes, Managing Director of Wammes und Partner GmbH.

About Wammes & Partner GmbH

With more than 25 years of experience in development and manufacturing of flat panel displays and displays for extreme applications, Wammes & Partner GmbH is the contact point for all questions regarding electronic displays and trouble shooting – in all applications and for all manufacturers. In the Electronic Display Center in Gundersheim with its own research department, experience is shared with professional users, manufacturers and integrators from the B2B sector on topics such as optical bonding, embedded displays, heat management, volumetric display or special light sources. Wammes & Partner supports its customers from trouble shooting and bug fixing to failure analysis, material procurement, consulting and training.