At the recent Display Week, there were many papers presented on rollable and flexible displays and Samsung set out the importance and significance of stretchable displays. Most of the talks focused on OLEDs, but an interesting one from Nitto Denko covered flexible LCDs.

While OLEDs are exciting, LCDs have advantages in cost and lifetime as well as higher brightness, potentially. In reflective configurations, LCDs can have very, very low power consumption.

Developments in flexible LCDs have been made in the past by companies such as Flexenable and Merck (and reported on Display Daily). Unfortunately, the difficulty of making flexible and curved displays increases as the display gets thicker and thicker. OLEDs can be incredibly thin, which makes them attractive. LCDs have three layers, one each of glass or plastic on the outside of the LC ‘sandwich’. Even with thin layers, having three is a challenge.

Nitto Denko has made the bending slightly less of a challenge by developing a new polariser that is robust enough that it does not need to be mounted on a glass or plastic substrate and can be used as the outer layer of the LCD. It is also very, very thin. The material was presented at Display Week in session 38.3 (Ultra-thin Flexible LCD Based on Single

Substrate Using Deformable Polarizer)

Get the Volts to the Pixel

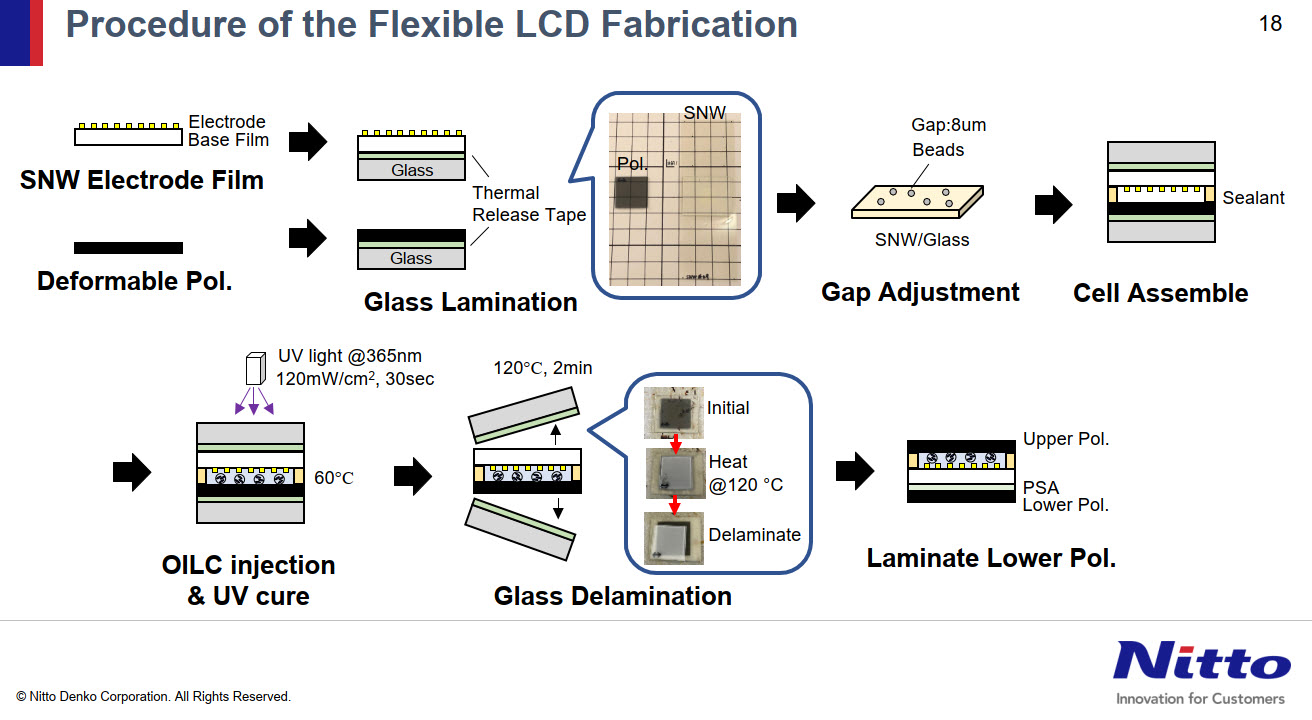

Another challenge of making flexible LCDs is that you need to get the drive voltage to the pixel and that needs a transparent electrode. ITO is the material used on most LCDs, but is very brittle and really doesn’t work on flexible displays. Nitto Denko used a silver nanowire (SNW) material, as has been used in some flexible touch displays, to pattern the electrode on the flexible LCD.

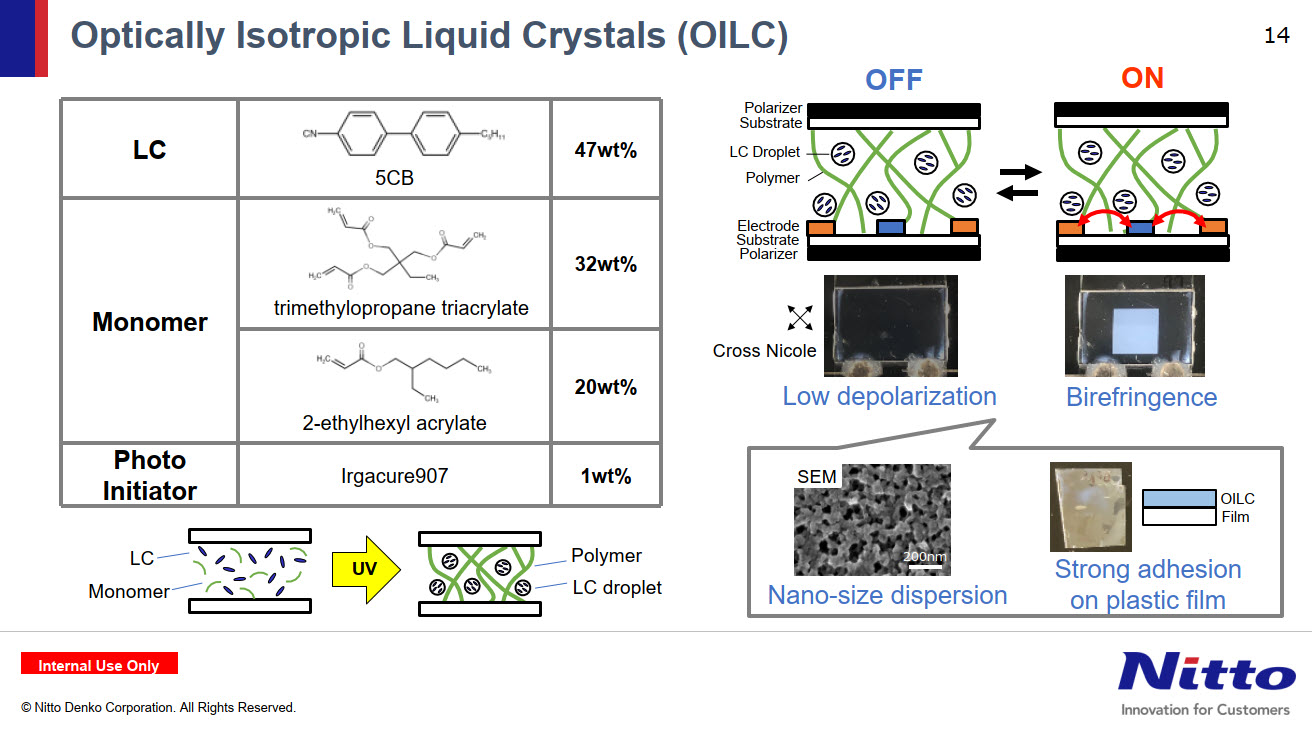

LCDs based on VA, TN or IPS liquid crystal modes use anisotropic liquid crystal materials. That is to say, the optical properties of the LC material are different in the various directions around the molecule. That means that the molecules need to be consistently arranged in the LC cell, another challenge when the LCD is going to be folded or bent. Nitto Denko used an optically isotropic LC (OILC) material and used polymer threads and 8?m beads between the top and bottom of the LC cell to maintain a consistent cell gap in the display. Without the polymers, the top and bottom substrates would come together where the display is bent.

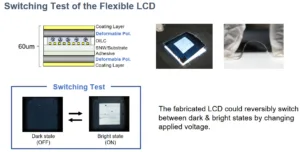

The firm makes films, so the polariser film was also researched. A ‘normal’ polariser layer would be around 47um thick and an ultra-thin polariser (UTP) (made on a sacrificial film and then transferred to a protection film) would reduce that to around 25?m (20?m for the protection film and 5um for the UTP. By replacing the protection film with a 5?m coating layer, the total thickness could be reduced to 10um. Event though it is very thin, the new polariser had better puncture strength than conventional UTP. It is also much easier to fold and deform than the UTP.

The company made some test displays and they can be curved to a radius as small as 1mm. When tested with a radius of 2mm, there was no change in the transmittance between the flat state (before or after bending) and the curved state. A test was also made of a reflective display using a stretchable mirror film on the back and a single polariser. That kind of architecture could enable very thin, flexible and very low power displays that could be ideal for wearable applications.

Manufacture is performed by laminating the flexible upper and lower polariser layers and base layer that has the SNW deposited onto layers of glass. Once the two assemblies have been united and the polymer between the top and bottom has been UV cured, the glass is delaminated. (BR)