Wearable devices, ubiquitous sensors, and more broadly the Internet of things will increasingly require truly flexible electronics systems that can sense, take actions, and communicate. Flexible hybrid electronics offers the promise of making the performance of traditional, bulky semiconductor devices and circuit boards available in formats that bend, stretch, fold and conform to the human body, vehicles, infrastructure and other objects.

NextFlex: A Manufacturing Innovation Institute

On August 28th, 2015, US Secretary of Defense Ashton Carter announced that the US government had signed a cooperative agreement with the Flextech Alliance to create a Manufacturing Innovation Institute for Flexible Hybrid Electronics. The Department of Defense pledged $75 million over a five-year period to fund the Institute. Flextech led a team of more than 100 companies, universities, and other organizations to propose plans for creating the Institute, developing a manufacturing technology roadmap, and structuring educational and workforce development programs.

The Institute, subsequently named NextFlex, is a public-private entity that is part of the National Network for Manufacturing Innovation, created by the Obama administration to increase advanced manufacturing in the United States. Each Institute is designed to address a particular technology area, funded by the Federal Government, with contributions from private sector companies, universities, state and local governments, and non-profit organizations. The institute will invest in development projects to increase the maturity of manufacturing processes and enhance the US ecosystem for flexible hybrid electronics.

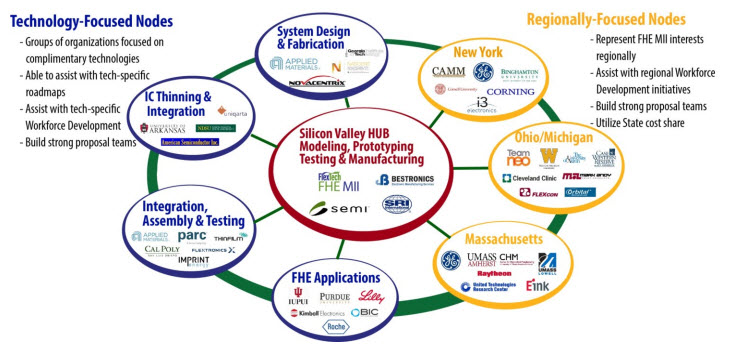

Headquartered in San Jose, California, NextFlex is operated by a professional staff in collaboration with representatives from the US Army Research Laboratory and the US Air Force Research Laboratory. NextFlex will operate through governing and technical councils, which will be comprised of members and government representatives. The organizations that were involved in the proposal development are now becoming formal members of NextFlex, as well as other companies and organizations who have become aware of the Institute. The members will help to set the technical direction of the institute programs and collaborate in carrying out development projects, and will have access to the results of institute projects.

Why Flexible Hybrid Electronics?

There is increasing demand for electronic systems that are flexible and have the ability to sense, process, take action, and communicate with other devices and networks. Applications include smart watches and other consumer wearables; human performance monitoring devices and “smart” bandages for medical treatment; structural health monitoring for aircraft and other vehicles and buildings, bridges, and other structures; array antennas that can be rolled, folded, or curved; and “soft” robotics for autonomous devices and advanced prosthetics.

However, current devices are limited on the one hand by the performance of flexible electronics, typically comprised of simple devices printed on polymer films or other flexible materials, and on the other hand by the packaging requirements of semiconductor chips, which are thick and inflexible. Flexible hybrid electronics is an emerging technology category that combines thin semiconductor chips and printed devices on flexible substrates, enabling high performance systems that can be worn on the body, integrated into clothing or other materials, or built into structures such as vehicles and infrastructure.

NextFlex will develop technologies for enabling commercial manufacturing of flexible hybrid electronics systems. Projects will be directed toward the development of materials, such as substrates, conductive materials, adhesives, and encapsulants; processes for printing of flexible components such as sensors, antennas, power sources, and structures such as actuators and microfluidic systems; techniques for thinning chips (or producing thin chips), assembling thin chips onto a flexible substrate, and connecting the chips and printed devices; modeling and design tools; and standards, testing, and reliability processes.

NextFlex’s Technical Council will develop and maintain a technology roadmap to identify gaps between state of the art manufacturing technologies and required capabilities. Project calls will be created to solicit ideas for conducting development projects to fill these gaps and demonstrate flexible hybrid electronics technologies. These projects will be awarded through a competitive bid process, and will be at least 50% funded by cost sharing by the award recipients.

In order to assure that there is an educated and trained workforce to support advanced manufacturing of flexible hybrid electronics, NextFlex will conduct projects to assess requirements and needs of industry, create content, and work with educational institutions and manufacturers to educate and train technicians, engineers and researchers.

NextFlex Status

Less than six months since the award, NextFlex has created a startup management team, created membership and intellectual property agreements, signed up 15 founding members, initiated its first project call, and started creating a plan for a demonstration facility to be located in Silicon Valley. Selection of the first projects will be announced in February, and work is expected to begin in the second quarter of 2016. NextFlex will hold governing and technical council meetings at the Flex Conference in Monterey, California, the week of February 29th. – Paul Semenza – Director of Commercialization, NextFlex

Paul Semenza is responsible for membership, partnerships, and development of the institute business model at NextFlex. From 2008 to 2014, he was President, Analyst Services at the NPD Group, where he was responsible for the DisplaySearch and Solarbuzz market research businesses, having previoulsy managed display market research at iSuppli and its predecessor Stanford Resources from 1997 to 2008. Prior to his career in market research, he worked in technology policy assessment at the National Research Council and the U.S. Congress, and as a member of the technical staff at The Analytical Sciences Corporation. He received BS and MS degrees in Electrical Engineering from Tufts University, and the MPP degree from the Harvard Kennedy School.