Two new technologies caught my eye recently, both related to 3D or 3D-like imaging. Both technologies are in the academic research stage, so don’t expect either one to have an impact on the display market in the near- or even medium-term. There could, perhaps, be spin-off technologies with a shorter-term impact.

Reflective Metasurfaces

First, there is a report titled “Reflective Metasurfaces for Incoherent Light To Bring Computer Graphics Tricks to Optical Systems” by Dr. Alexander E. Minovich, who is currently the Royal Society Newton International Fellow at the Department of Physics, King’s College London and his five colleagues. I’d heard of metamaterials before but this is the first mention I’ve come across of a metasurface.

This technique does not, in fact, produce 3D images with parallax – the image produced appears to be on the surface of the material, not in front or behind, as would be possible if the metasurface produced a true stereoscopic 3D image. Instead, the metasurface is capable of producing a Trompe-l’œil (fool the eye) 3D image. What the metasurface does is to reflect white light the way a real surface would. One of the results of this is that when the source of the ambient light is moved around, the relative brightness of a surface changes, just the way the relative brightness of an object would change. The metasurface is a layered structure with precisely positioned sub-wavelength nano-features embedded in it which is, in turn, designed by a computer graphics technique called Normal Mapping. The technique is not “holographic” and does not depend on coherent light.

Representation of the metasurface (left) plus how the image will change as the source of the ambient light moves. (Right) (Credit: American Chemical Society)

Representation of the metasurface (left) plus how the image will change as the source of the ambient light moves. (Right) (Credit: American Chemical Society)

Dr. Minovich told Photonics.com, “Holograms represent 3D photos where lighting and shading of an object or scene is fixed. With the normal mapping technique, the lighting and shading changes similarly to real 3D objects when the illumination source is moved. If you illuminate the structure from the right, bright areas will be on the right and shaded areas on the left. When you bring the light source to the left, the position of the bright and dark areas will change accordingly.”

This technology, as described in this paper, will only produce fixed images, even if the appearance of the image can change as the incident light changes. In principle, the technology can be applied to larger surfaces and, perhaps, even be done with roll-to-roll processing to make very large images. Unfortunately, these images will not be electronically controllable, as needs to be done in a true dynamic display. However, the paper says the image “…is brighter than a standard white paper by up to 2.4 times.” This should be interesting to people working on full-color e-paper, which currently is about 1/3 the brightness of white paper when showing white. Could this technique be used to make e-paper brighter? This might be the biggest short-term impact of metasurface technology.

While I don’t know how to turn the technology in this paper into a true display, I suspect Dr. Minovich has ideas worth pursuing in the lab. After all, one of his other papers is titled “Electro-optical switching by liquid-crystal controlled metasurfaces.” That sounds like a display to me.

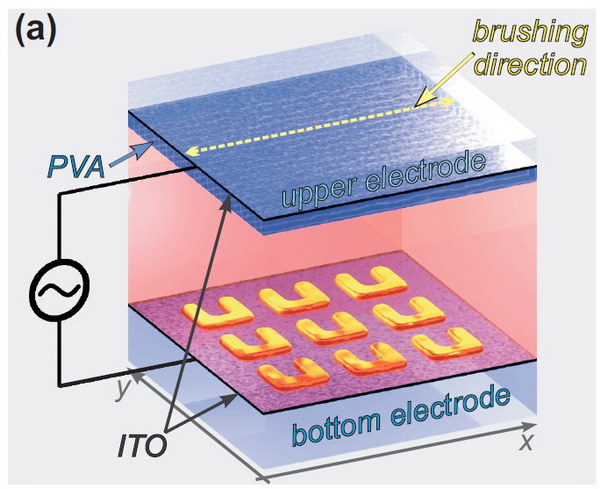

LCD-controlled metasurface. The metastructures are gold split-ring resonators (SRRs) covered by a transparent ITO layer. Dimensions of the individual SRR meta-atoms are 138nm x 124nm on a 300nm square pitch. (Credit: OSA)

LCD-controlled metasurface. The metastructures are gold split-ring resonators (SRRs) covered by a transparent ITO layer. Dimensions of the individual SRR meta-atoms are 138nm x 124nm on a 300nm square pitch. (Credit: OSA)

Volumetric 3D

The second approach to 3D is a more conventional volumetric 3D system, with a twist and some potential benefits compared to prior volumetric 3D systems. This was reported by Shreya K. Patel, Jian Cao & Alexander R. Lippert, all from Southern Methodist University (SMU), in a paper in Nature Communications titled “A volumetric three-dimensional digital light photoactivatable dye display.”

The technology, called the 3D digital light photoactivatable dye display by the authors, or 3D Light PAD for short, is based on a special class photoactivatable dyes. The paper lists seven different categories of these dyes but I’ll spare you the chemical names – they don’t mean much to me and probably don’t to most Display Daily readers, either. These molecules undergo a photochemical reaction to toggle between at least two different molecular states that can vary in shape, colour, fluorescence and other molecular properties. If this reaction is reversible, then these compounds are referred to as photoswitches.

The operating principle of a 3D Light PAD rests on using small photoswitch molecules with a particular set of optical properties:

- a non-fluorescent ‘off’ state,

- a fluorescent or visible absorbing ‘on’ state,

- access to the ‘on’ state by illuminating at a wavelength outside of the florescence absorbance spectrum,

- a fast rate of photoactivation and

- a fast deactivation to the ‘off’ state.

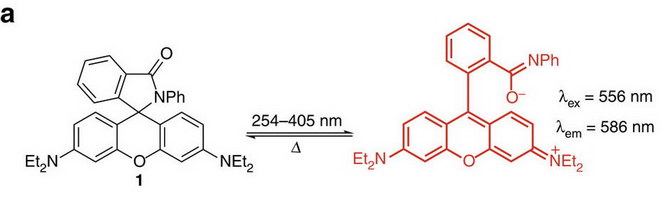

The 3D Light PAD is designed around a class of photoswitch compounds (N-phenyl spirolactam rhodamine B) that can be switched from a non-fluorescent to a fluorescent isomer using ultraviolet light. The florescent state then, over time, decays back to the non-florescent state. In the florescent state, the material absorbs light at 556 nm (green) and emits light at 586 nm (yellow). Professor Lippert points out that color-selective photoswitch molecules are not something new – photoswitch compounds in our eyes convert input light into the electrical signal processed by the brain into “color.”

Photoactivation of N-phenyl spirolactam rhodamine B by UV light from a non-florescent to a florescent state (Image: SMU)

Photoactivation of N-phenyl spirolactam rhodamine B by UV light from a non-florescent to a florescent state (Image: SMU)

Unfortunately, at room temperature, the decay to the non-florescent state for this material occurs over 600 seconds or more and few people want a display with a ten minute refresh rate. Adding a few parts-per-million trimethylamine to the solution dramatically speeds up this decay to the non-florescent state, allowing a 30Hz frame rate in the 3D Light PAD system. A large part of the data reported in the paper relates to the exact concentration of trimethylamine needed to optimize display system response time.

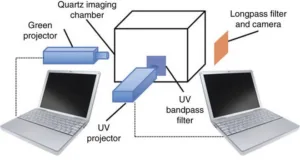

Block diagram of the 3D Light PAD System (Credit: SMU)

The 3D Light PAD system two projectors, a DLP projector with UV illumination to activate the material in a pattern of 3D Voxels and a green projector to cause the activated voxels to emit yellow light. The 3D image from the DLP projector defines each image to be shown by activating the material throughout volumetric region. The bar of green light then activates individual planes and causes the current plane to emit the yellow image light.

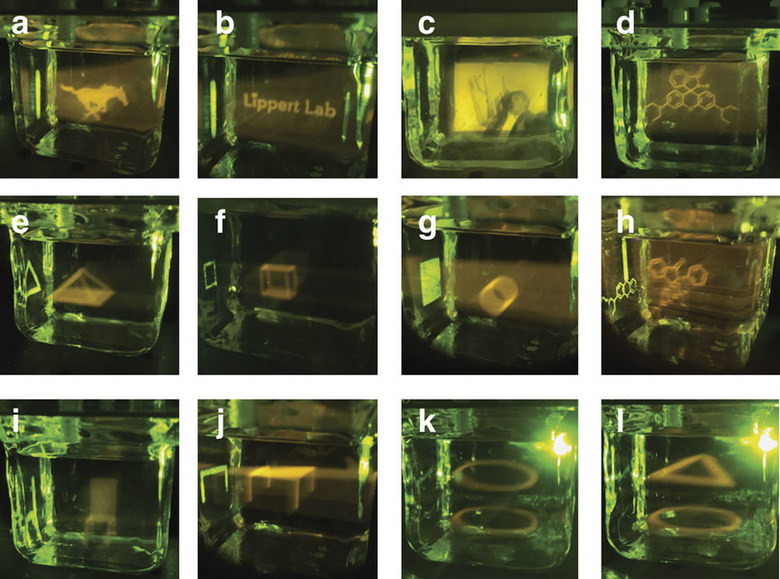

Images produced by the 3D Light PAD system (Credit: SMU)

Images produced by the 3D Light PAD system (Credit: SMU)

In the image above, image A is a still from a 30Hz movie of the SMU mascot, a galloping mustang; B and C are still 2D images; and D through I are still volumetric images of various shapes, including the N-phenyl spirolactam rhodamine B molecule. The current, first generation 3D Light PAD has 183,000 voxels in a volume of 125cm³ with a spatial resolution of 230?m. Each voxel has a volume of about 0.68mm³. While the images are currently only yellow, the researchers are looking into ways to make red, green and blue.

The researchers also recognize that a liquid in a large quartz bathtub is not a good path to a commercial 3D volumetric display. They are looking in two directions:

- Embedding the active material in a solid polymer, avoiding the liquid and

- Using an aerosol of the liquid.

I find this second approach intriguing. A solid polymer volumetric display would probably weigh too much to make a practical volumetric TV, or even a smaller volumetric medical display. But an aerosol dispersion in a transparent container would be much more manageable, at least in terms of weight. Plus, a free-space aerosol dispersion would bring to life Professor Lippert’s dream of recreating the Star Wars display of Princess Leia. –Matthew Brennesholtz

Princess Leia warns the Rebels in “Star Wars” (Credit: George Lucas)

Princess Leia warns the Rebels in “Star Wars” (Credit: George Lucas)

Analyst Comment

These two technologies represent two very different paths to next-generation 3D displays. Neither one is likely to come to commercial fruition for years to come. However, I’m always happy to see academic researchers tackle display-related problems that may generate new commercial display technologies for the future. -MSB