For the last few weeks, I have been threatening to look at a technique of LCD manufacturing, known as MMG – although I have seen many different versions of what this acronym stands for!

I’m going to define the acronym as ‘multi mother glass’, but you will hear others, including ‘multi-model glass’.

Since the first development of LCD-making, multiple panels have been made on a single substrate. The size of panels made on a substrate is usually the same – for example in the early days when notebook panels were the main market, vendors would make 6 panels of 13.3″ diagonal or 3 at 15.6″. At Gen 5, panel makers made 9 or 12 19″ 5:4 panels for monitors. At Gen 6, you could make eight 32″ or six 37″ panels. Sharp’s G10 fab (about to lose its position as the only fab above G8.X as it will be joined next year by BOE’s G10.5 fab) has 2880 x 3130 mm substrates that can make eight 60″ or six 70″. BOE’s G10.5 will be able to make eight 65″ panels.

Three Key Factors in Efficiency

Making all the same size on a sheet is the fastest way to make panels and that is one of the critical factors in LCD factory efficiency. There are three big factors in assessing the efficiency of an LCD fab. One is the tact time – the time it takes to process a sheet. Making all the panels with the same size and resolution is the fastest way to make panels. Mixing different sizes on the same sheet slows things down, so the makers will avoid this if they can.

The second is the yield – the percentage of ‘good’ panels that can be made. Making just one size helps a little with improving yield because the manufacturing is slightly faster and simpler.

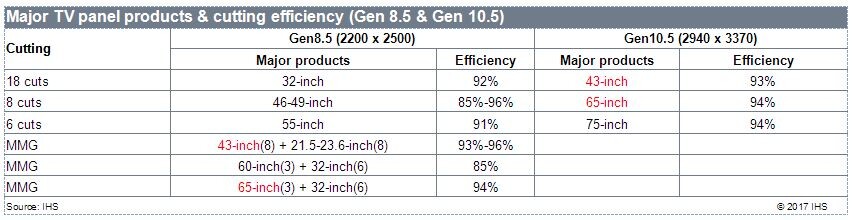

The third factor is the cutting efficiency – that is to say how much of the total surface glass of the substrate you can use and sell. And that’s where MMG comes in. One of the sizes that is expected to be most popular in the TV market as we go forward is 65″, so the ideal solution for making those is to use a specially planned G10.5, as BOE will do to make eight panels at a time on a single substrate. Panel makers need to get over 90% efficiency to be competitive in the market.

Panel making can be economic if glass usage is over 90%. Table:IHS – re-used with permission

Panel making can be economic if glass usage is over 90%. Table:IHS – re-used with permission

Not Many G10+ Fabs Outside China

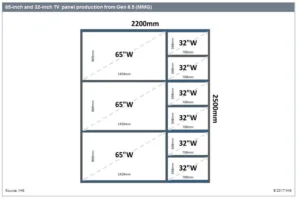

However, panel makers do not have G10 fabs or bigger in Korea or Taiwan . They have fabs in the G8 class and, unfortunately, G8 was designed for 55″, really, and six 55″ panels can be made efficiently on a 2200 x 2500 substrate, but only three 65″ panels. In a G8.5 fab, and there are a number of these in China, the glass efficiency of making 65″ alone is just 64% according to IHS – over a third of the (expensive) glass is simply wasted and in such a fiercely competitive market such as LCD-making, that’s not sustainable. However, it turns out that if you plan the layout correctly, you can make six 32″ panels along one side of the glass, so that the glass is not wasted.

At G8.5, MMG and making 32″ alongside 65″ can mean glass efficiency in the 90%+ range rather than 64%. Image:IHS – re-used with permission

IHS has calculated that in 2016, 92% of all the 65″ LCDs made by Korean makers used MMG, while in 2017 it expects this to reach 98%. (The alternative is to make 65″ on a G6 plant which can make two 65″ panels. As the overall area of a G6 sheet is slightly less than half of a G8 sheet, the cost is much more acceptable. However, G6 fabs are being developed to make higher quality panels such as LTPS-based units, so that’s not a great solution. Furthermore the Chinese makers do not have many G6 plants). The ETNews has reported that LG Display will switch all its production in Guangzhou, Chine in 2018 to MMG.

The slowing in tact time can be enough of a problem that MMG can reduce the effective throughput of the industry and IHS has calculated that the capacity of the industry in 2017 was reduced by around 4% because of the use of the technique.

What About Half Substrates?

At one point last year, to get around this problem, panel makers thought about making panels that were ‘half G10.5’ – with a substrate that is half the length of a G10.5, allowing four 65″ panels to be produced efficiently without needing to build a new G10.5 plant. However, that doesn’t seem to have been adopted as the cost would not be as good as for a full G10.5 and the existing fabs would have needed significant re-engineering.

And OLEDs?

Of course, the same logic applies in OLED manufacturing, but at the moment, according to DSCC, going to MMG for OLED needs new exposure equipment from Canon and that won’t be available until 2019. However, when that is possible, LG should be able to make three 65″ and two 55″ from single G8.5 substrate (and AUO is reported to be looking at the same configuration). At the moment, LG can make six 55″ on a G8.5 fab, or three 65″, so there is a significant cost penalty to move to the larger size.

The other complicating factor in MMG is that the different sized panels need to use the same technology. So, if you make monitor panels on part of the substrate, these need to be IPS or VA to match the technology of the larger panel.

(In researching for this article, I looked back in our database and found the first reference to this technique of MMG in June 2004, by the then LG Philips LCD company! I couldn’t find it in my database, but my memory tells me that Sharp was the first to bring the technique into use.) (BR)