MicroLED displays have long been heralded as the future of display technology, promising unparalleled brightness, response times, and energy efficiency. But almost two decades after the first MicroLED prototypes, widespread commercial availability remains elusive.

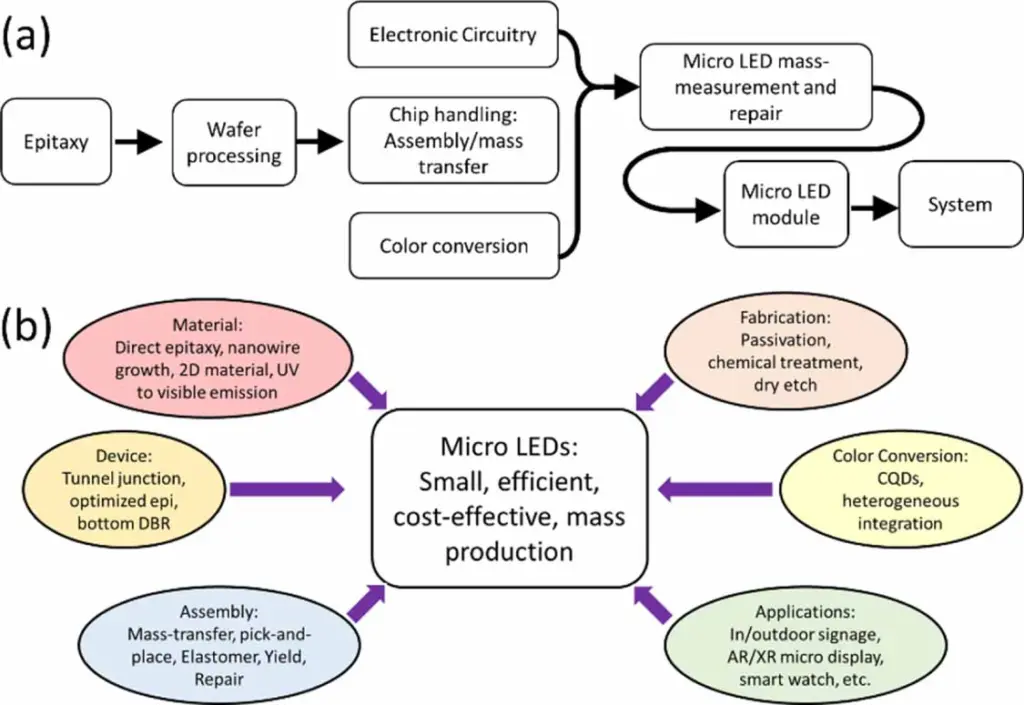

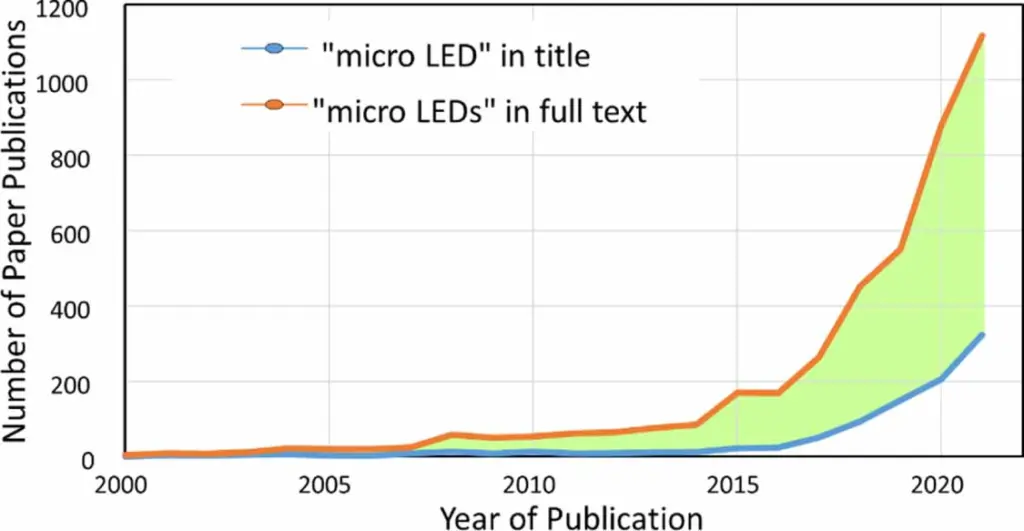

In a paper published in the Journal of Physics: Photonics, researchers from academia and industry collaborated to provide an updated roadmap of the progress and remaining challenges facing MicroLEDs. They trace the origins of MicroLEDs back to the early 2000s, when researchers realized that shrinking LEDs to the microscale enabled intriguing physics like enhanced spontaneous emission and lower lasing thresholds. Practical applications soon followed, with MicroLEDs eyed for next-generation displays, VLC, and biomedical devices.

Interest in MicroLED displays, in particular, has exploded in recent years thanks to demand for high resolution VR/AR and transparent displays. Compared to LCD and OLED, MicroLEDs offer superior brightness, faster response times, and longer lifetimes. Consequently, companies like Samsung, LG and BOE have showcased MicroLED prototype TVs and monitors.

But significant barriers remain before volume production can commence. At sizes below 10 microns, MicroLED efficiency drops drastically due to surface recombination and plasma etching damage. New solutions like ALD passivation have improved efficiency somewhat, but red and UV MicroLEDs still lag far behind blue and green. For full color displays, techniques like quantum dot color conversion help compensate but introduce complexity.

Mass transferring millions of MicroLED chips onto circuitry, known as micro-assembly, is extremely challenging. The current pick-and-place approach is far too slow and expensive for commercialization. Alternative techniques like stamping show promise but still struggle with scale-up and non-uniformity issues. Defects from MicroLED fabrication and transfer necessitate difficult repair processes to meet consumer expectations.

Monolithic integration, growing MicroLEDs directly onto driving circuitry, is enticing but restricted by material challenges. Emitting pure red with InGaN is difficult due to high indium incorporation. Novel nanostructures like nanowires help mitigate this but require intricate fabrication. Integrating multiple colors monolithically also remains an open problem.

Experts suggest enhancements like tunnel junctions could boost efficiency by improving current spreading and light extraction. New substrates better lattice-matched to high-indium InGaN may also enable efficient red emission. For manufacturing, roll-based stamping exhibits potential for scalable micro-assembly.

But clear solutions are still distant for most challenges, leading researchers to acknowledge meaningful commercialization is at least five years away, with perhaps ten years needed to perfect monolithic techniques. Consequently, while MicroLEDs represent an exciting future display paradigm, claims of them enabling next-generation smartphones, AR glasses, and wall-sized TVs in the next couple years appear dubious.

Significant materials research, nano-fabrication advances, and equipment innovations are first needed to address the roadblocks outlined in this paper. And crucially, MicroLED manufacturing must become cost-competitive with existing OLED factories. It is unlikely brand-name consumer MicroLED products release before the latter part of this decade.

The Massive Challenge of MicroLED Mass Transfer

One of the biggest roadblocks standing in the way of commercially viable MicroLED displays is the monumental challenge of mass transfer. This crucial manufacturing step involves precisely placing millions of tiny MicroLED chips onto circuitry to create high-resolution displays.

As experts from the paper explain, current pick-and-place methods adapted from LED backlights are far too slow and imprecise for micro-assembly. At best, conventional die bonders can only transfer 5-40 chips per second. To make an 8K display, around 25 million transfers are needed, making the process totally impractical.

Alternative techniques like stamping can handle more chips in parallel but struggle to provide uniformity at larger scales. Statistical self-assembly methods can achieve higher throughputs but lack deterministic control, resulting in unacceptable dead pixel counts. Even innovative technologies like laser transfer printing remain restricted to shuttling MicroLEDs onto temporary carriers, not directly onto display backplanes.

Fundamentally, handling large numbers of tiny MicroLED chips while maintaining precision across large display areas represents an enormous manufacturing challenge. Experts estimate that for commercial viability, mass transfer systems must deliver per-panel yields exceeding 99.999% to minimize dead pixels. Such accuracies remain difficult to consistently achieve with current solutions.

With clear paths to ultra-high volume micro-assembly unclear, and radically new transfer technologies likely needed, experts caution that cost-effective mass production of MicroLED displays maybe a few years aways. Despite promising progress, mass transfer remains a critical roadblock on the route to revolutionary MicroLED displays. Yet, there are indications that commercial interests may be accelerating the progress of manufacturing technology and that we may arrive at solutions earlier than anticipated.

So, it seems that realizing the potential of MicroLEDs at scale remains a gradual, multi-year process. Early prototypes and demos will continue trickling out, but pervasive MicroLED commercialization is still firmly on the horizon according to this comprehensive research review. Patience and persistence will be required before MicroLEDs illuminate store shelves. But, with competition for OLEDs heating up between Korea and China, it wouldn’t be surprising to see MicroLED technology be pushed forward to create competitive advantages.

Reference

Lin, C.-C., Wu, Y.-R., Kuo, H.-C., Wong, M. S., DenBaars, S. P., Nakamura, S., Pandey, A., Mi, Z., Tian, P., Ohkawa, K., Iida, D., Wang, T., Cai, Y., Bai, J., Yang, Z., Qian, Y., Wu, S.-T., Han, J., Chen, C., … Fang, Y.-H. (2023). The micro-LED roadmap: Status quo and prospects. Journal of Physics: Photonics, 5(4), 042502. https://doi.org/10.1088/2515-7647/acf972