Display Daily is a media sponsor for the Techblick Mini- and Micro-LED and Quantum Dot events on 30th November and 1st December. The firm has kindly provided us with a number of interesting extracts from some of the talks that will be give at the event and we have put them in two articles – one today and one on Tuesday of this week (they will not count as in your free articles if you have a free registration).

In this article, using select technology slides, we highlight several interesting advancements in MicroLED and/or QD displays. More specifically, we cover 3600PPI “Silicon” Displays | Gravure printed microbumps | Electrohydrodynamically printed QD color converters | Laser LLO and Transfer for MicroLEDs | QD vs Phosphors | Energy saving credentials of microLED

Note each of the articles has a ‘gallery’ with multiple graphics. Click on the first one to open them and use the arrow keys to navigate)

Can lasers help in MicroLED display production?

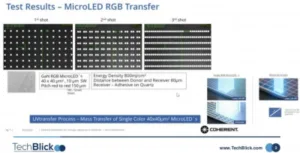

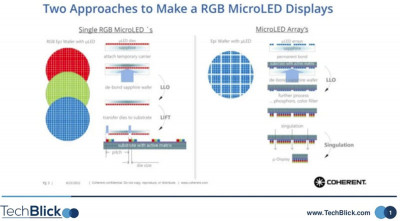

One of the biggest manufacturing challenges in microLED display production is the transfer step given the speed and yield requirements. As shown in the slides below (Gallery 1) by Oliver Haupt from Coherent Inc., lasers can play an important role in this step, both when all three colors (R G B) microLEDs and also when only blue microLEDs need to be transferred.

The process flow for both cases is shown below. In case of RGB MicroLEDs, first a temporary carrier is attached to the sapphire substrate on which GaN microLEDs are grown. Laser Lift Off (LLO) is deployed to de-bond the sapphire substrate, releasing the carrier wafer with the detached GaN microLEDs. Next, controlled UV spots are used to release the individual microLEDs onto the final substrate holding the TFT active backplane layers. These process can be repeated three times, each time for a different microLED color. In all steps, of course, excellent and optimized control of the laser profile/parameters in harmony with the right adhesive material properties are required.

In the case of blue-only microLEDs, the final backplane substrate is brought into contact with the GaN sapphire substrate. The GaN uLEDs transfer to the final substrate via the LLO process. Three color capability is then achieved by color conversation, e.g., QDs or small-sized phosphors

The results show the example of microLED RGVB transfer. The parameters are shown in the slide including microLED size, pitch, laser energy density, donor-receiver distance, etc. It can be shown that a different color is transferred with each shot. Thus, in three shots all R G B microLEDs are placed at the right spot! As the subset in slide 2 shows, the laser can in each step/shot process an area of roughly 2.83cm².

MicroLEDs: can they help overcome the energy gap in electronic devices?

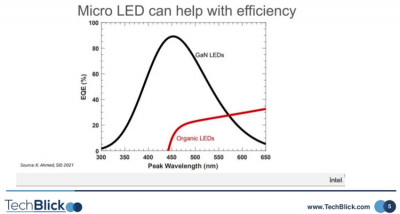

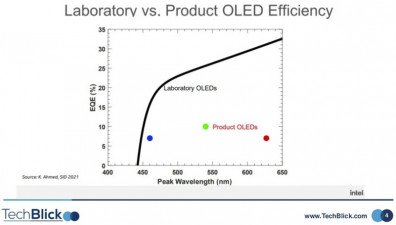

Why can microLED technology help narrow the energy gap in electronic devices? @Khaled Ahmed from Intel Corporation offered a data-rich unique assessment at TechBlick’s display event in 2021.

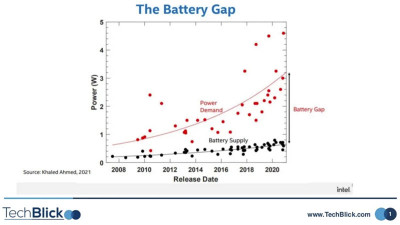

The first slide (Gallery 2) shows the battery gap- Ahmed has collected data by year showing that power demand of phones far exceeds the power supply level of batteries, creating a “battery gap” which widens each year as more power-hungry features are added whilst battery technologies improves only incrementally. Some 70% of power consumption of a mobile phone or tablet is by the display, showing its outsize importance in shrinking this gap.

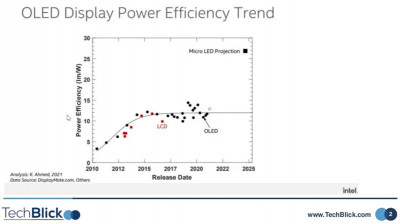

The second slide (Gallery 2) shows the improvements in the efficiency (lm/W) of ‘released’ OLED devices per year. The OLED efficiency has clearly plateaued in produced or released products. The backdot represents the projected potential of microLEDs, showing how the microLED technology can be a game changer.

The third slide (Gallery 2) shows that there is a gap between EQE of laboratory OLEDs and that of released products. The origins are not clear but likely involve trade-offs necessary in production and trade-offs between lifetime stability and EQE.

The four side compares the efficiency of GaN LEDs at various wavelengths vs organic LEDs (from previous slides). It shows that GaN LEDs offer dramatically higher EQE levels compared to OLEDs at all wavelengths except red. Indeed, there is a red efficiency gap in GaN microLED technology, the filling of which is the subject of intense global R&D

These charts clearly demonstrate that while OLED technology seems to have plateaued and thus will not likely ever overcome the Battery Gap, the emerging microLED technology offers high promise to do so. Of course development and manufacturing of microLEDs involves other challenges such as rapid transfer as well as high-yield production which we will discuss elsewhere.

Phosphors or QDs for color conversion in LCD and microLED ? Which will win?

This is an interesting and evolving technology space to watch. James E. Murphy et al from GE Research have developed best-in class narrowband red and green phosphors, and are now evolving the technology towards microLEDs and on-chip integration.

The red KSF phosphor is an excellent narrow band color converter for wide color gamut displays. It emits 5 peaks, each of which exhibits an ultra narrow 5-nm FWHM. The main peak is centred around 631nm. It is a stable material under high light flux and high temperature conditions. Indeed, it can be on-chip integrated as a direct replacement for existing yellow phosphors. It is a major commercial success with >19 licensees and >40 billion (and growing) KFS-containing LEDs sold worldwide into the display industry.

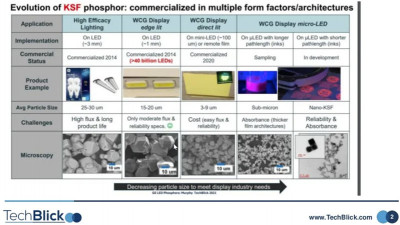

As the slide below (Gallery 3), presented at TechBlick July 2021, shows, the KFS technology is evolving. At first in 2014, the average particle size was a 25-30?m. It is now down to 3-9?m and evolving towards sub-micron and even nano-sized particles, enabling direct integration with microLEDs of today and tomorrow! This is an important technology trend because it brings the QD vs phosphor competition even to the microLED space (previously QDs were the only game in town due to their small size).

Furthermore, GE’s KSF can now be formulated into air-stable inks based on encapsulant-free phosphors suitable for inkjet printing without nozzle clogging. It means that it can be even printed as a color converter atop microLED, in particular allowing one to use efficient blue microLEDs to create red color and/or only transfer a blue microLED color.

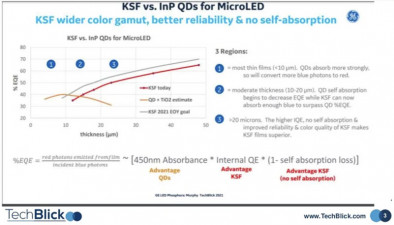

James E. Murphy offers also an interesting comparison of Cd-free InP QDs vs KSF for microLEDs. It argues that at very thin films (<10?m), QDs are more efficient. However, as the layer is thickened, perhaps to prevent blue color leakage, self-abosrption effects can kick-in, reducing the EQE. Thus, it is argued that KSF clearly wins at >20?m thickness given that it has no self absorption.

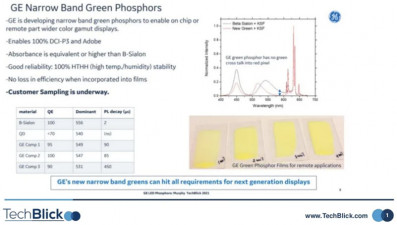

Finally, there is lack of ultra narrowband green phosphors leaving the space open to QDs. In particular, green perovskite QDs are very strong in this field. However, GE is advancing the development of its narrow-band green phosphors. As shown below, these materials enable 100% DCI-P3. The performance is comparable to Beta Sialon but without crosstalk with a KSF red emitter. Furthermore, it offers 100% HTHH stability, enabling direct on-chip integration. Finally, it appears to have QE levels approach >90%. Of course, just like KFS, it has a slow PL decay time on the order of 90-450?m (QD is ns)

You can hear more about all of these topics at Techblick’s first-ever specialist microLED and QD event. (KH)