Macroblock is always an interesting company to engage with as the firm has a dominant position in the supply of driver chips for LED direct view displays around the world. It also supplies drivers for miniLED backlights. The company held an event online this week and we logged in to see what was new.

The event used virtual production (VP) technology and that was a significant topic for the event. Covid has created an opportunity for virtual production as travel and global mobility has reduced and Macroblock has teamed with Moonshine in Taipei as a partner for the application. It used Moonshine for this production. (I have heard from market actors that virtual production has been a key new application for companies that had been in rental and staging, which, of course, has almost disappeared over the last couple of years).

A New Chip for Virtual Production

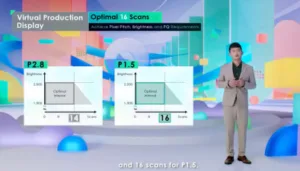

Cloud Wu was the first product manager to speak and he described a new chip designed specifically for VP use. There are particular challenges in this application. Creating true to life backgrounds needs particular hardware depending on how it is to be used. LEDs in the pitch range of P2.8 (2.8mm) down to P1.5 are optimum, with the larger ones ideal for distant backgrounds and P1.5 for close-ups. Brightness really needs to be good enough for HDR with up to 1000-2000 cd/m² available to be able to show a full range of scenery. The firm found that 16 scans (time multiplex) is the optimum to achieve this level of brightness. (there’s a backgrounder on the reasons for time-multiplexing LEDs here)

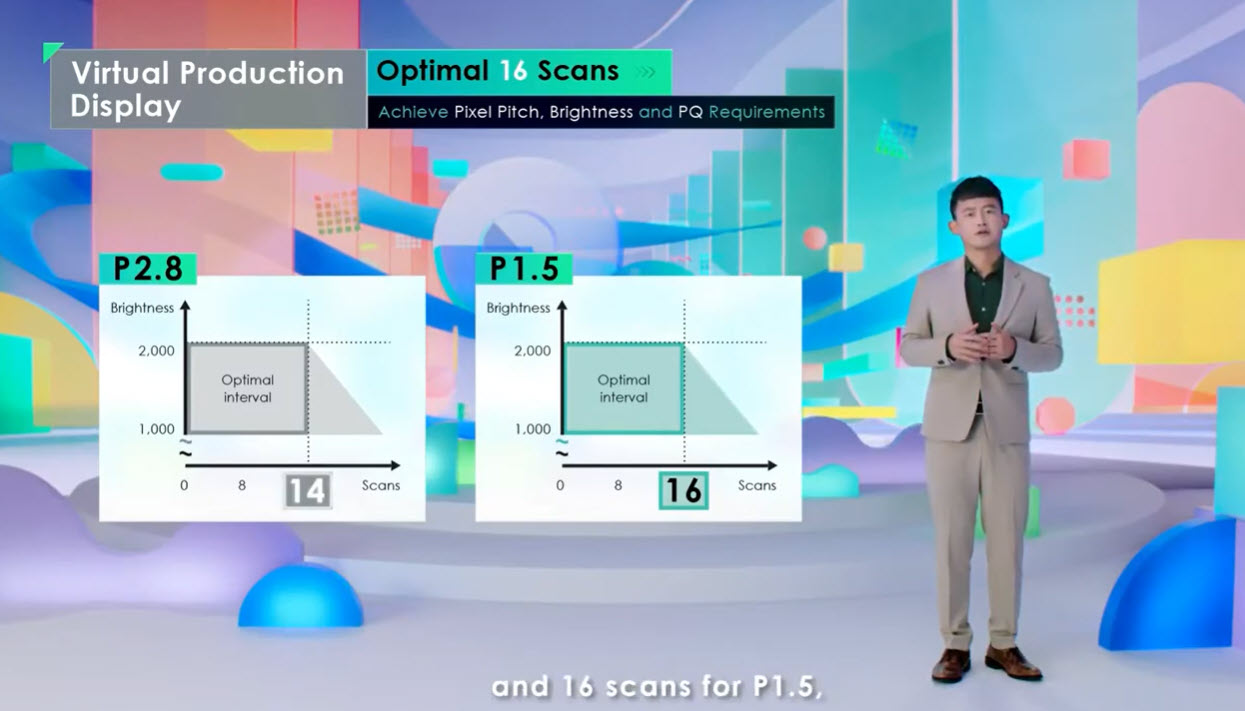

For accurate synchronisation using a genlock technology in the controller, the frame rate of the LED wall has to be at an integer multiple of the frame rate captured by the camera. With cameras operating at up to 120Hz, this can be tricky.

There are three particular challenges:

-

Motion Blur – caused if the LED does not have a fast enough frame rate

-

Scan Lines – dark and light bars caused by interference between the display and the scanning circuitry in the camera image sensor – which cannot be controlled externally.

-

Flicker at low greyscale – low refresh rates at low grey levels can lead to flicker.

These problems can be fixed in post production, but that means additional time and cost, so the firm has tried to solve them in the display driver.

Macroblock has addressed motion blur by using what it calls ‘enhanced PWM+’ to allow the display to be driven at a PWM rate of 7680 Hz. That rate supports 16 bit pixel depth at 120Hz (and twice the 3840 Hz of its previous ‘enhanced PWM’). PWM+ helps to reduce scan lines, but Macroblock has also developed a new ‘Hyper Vision Calculation’ (HVC) to minimise the effect. The HVC that reduces scan lines also reduces low grey level flicker..

Hung-I Cheng then spoke about the challenges of fine pitch displays. P1.2-2.5mm LEDs are the main range in the market at the moment and are starting to be used in monolithic displays in meeting rooms etc. miniLEDs at 0.5mm to 1.2mm pitch are starting to be used for high end TVs and microLED at pitches less than 0.5 mm are starting to be developed for applications including automotive consoles. Small LEDs need relatively low current which can be tricky to control accurately.

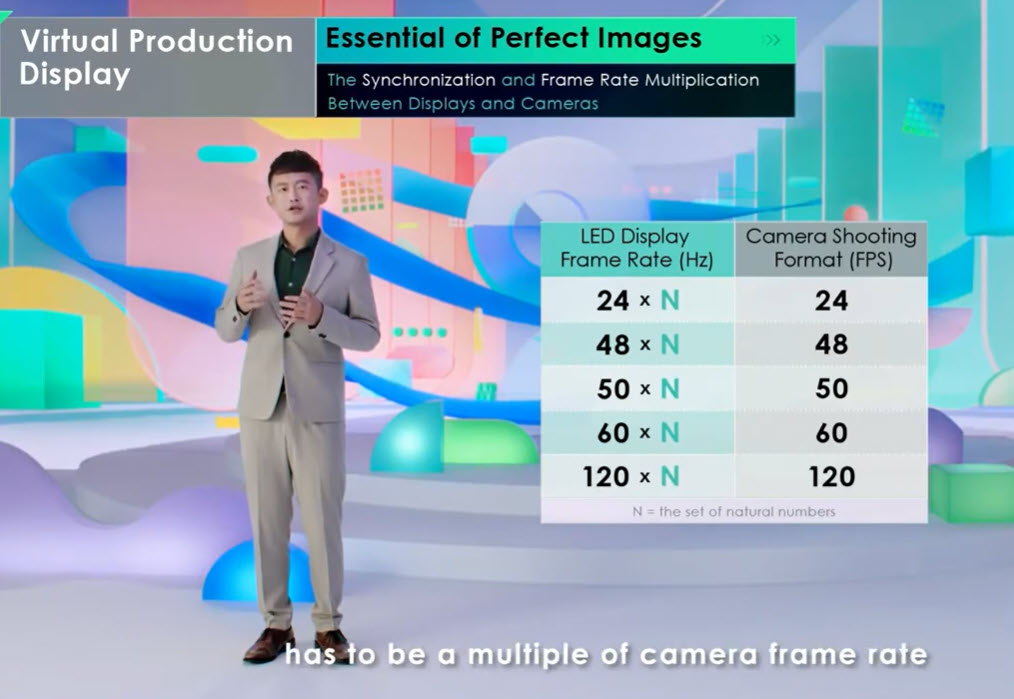

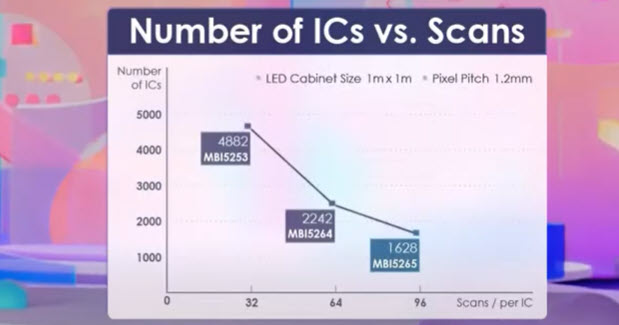

Although not directly connected to the driving technology, Cheng said that the lower limit of pitch for PCBs as a substrate for miniLED is about 0.4mm pitch and below that you need to change to glass which is suitable down to around 0.1mm pitch. Another factor is that as pixel pitch goes down for miniLED, the PCB complexity increases and 0.9mm pitch needs 6 layer PCBs, up from 4 layers at 1.8mm. Macroblock has ’64 scan’ (time multiplexing) technology in the chips it introduced last year (up from ’32 scan’) that reduces the number of layers needed for P1.8 and P1.5 displays. The new MB15265 boosts the number of scans to 96 and that means support down to 0.9mm pitch.

As the number of scans increases, the number of chips needed for driving the modules goes down as shown in the chart below.

The MBI5265 also includes uniformity improvements, especially at low grey scales.

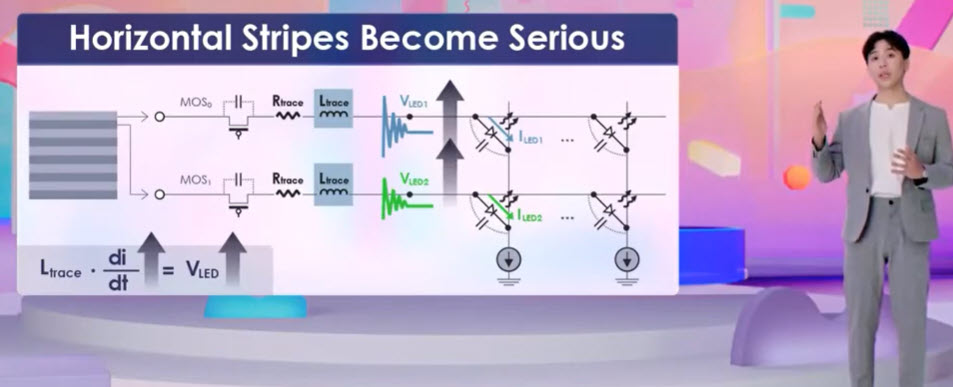

On the downside, although more scans helps with some aspects of driving, it can can cause an increase in horizontal striping. As the frequency of the drive signal increases, problems with parasitic inductance cause trouble with oscillation of the LED anode voltage. The new chip sorts out the problems with uniformity driving.

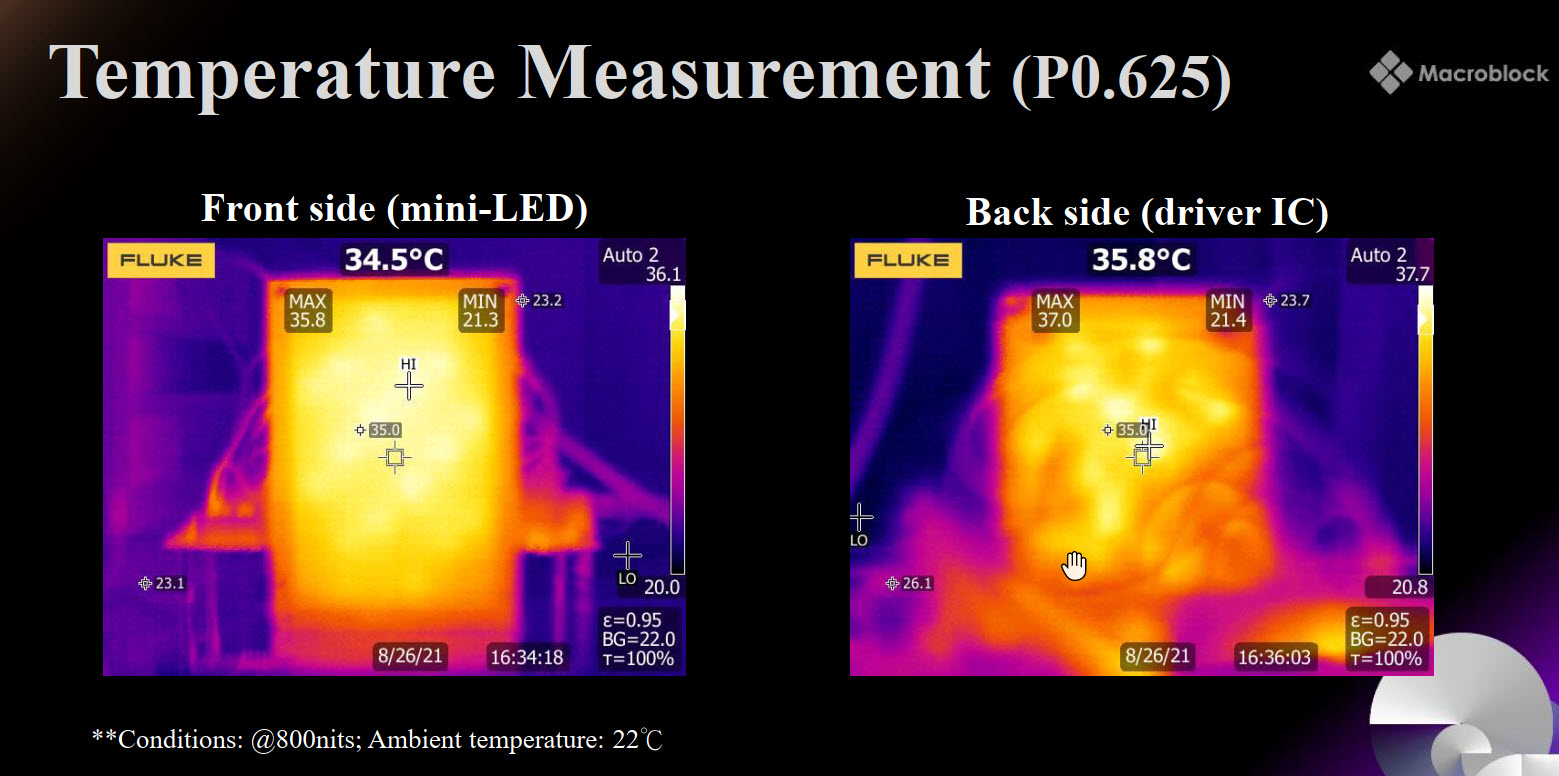

Going to smaller pitches, below 0.9mm pitch is supported by the MBI5864 chip for miniLED and with microLED and can go down to 0.4 mm pitch. Production is due to start soon. 64 scans are supported over 48 channels and features include low current driving (down to 0.1 milliamps, although the voiceover said 0.1 microamps!) and scan sharing with other channels (the firm has a patent for this kind of common cathode scan sharing). The chip is BGA packaged and can be mounted on the back of a 0.49mm miniLED layout. A 0.625mm pitch sample was tested for contrast and it achieved 25,000:1. The temperature was also under tight control at under 36° C.

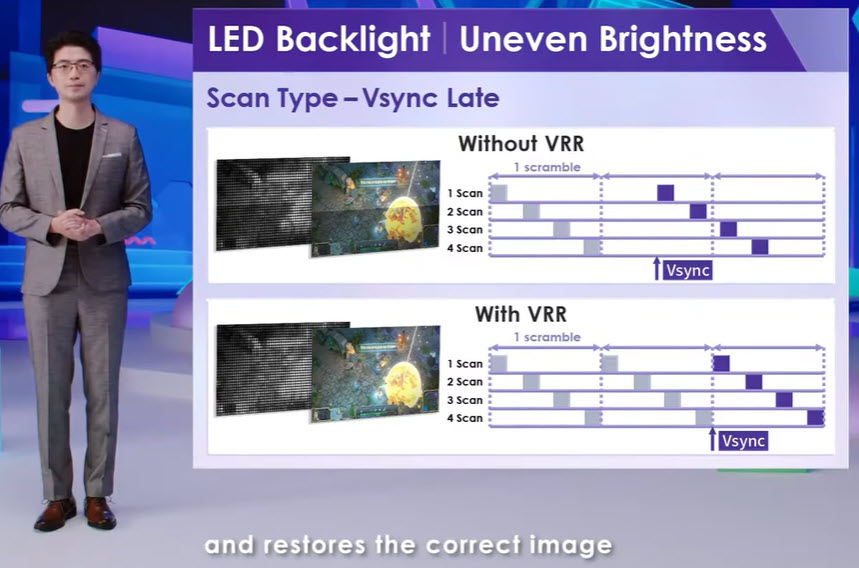

Chris Will Chen then talked about backlights in displays for gamers. He said that they need high contrast, high refresh and dynamic sync. After explaining variable refresh rates (VRR) he highlighted the flicker and uneven areas at the top or bottom of the display that can be caused by miniLED backlights. The flicker is caused by a mis-match in frame rates between the backlight and the GPU. The same mismatch can cause the uneven performance. For this reason, miniLED backlights need to be able to support VRR. Of course, the firm supplies suitable drivers. (BR)