The second morning opened with a session on lighting in display systems. Chin Chang (Semtech) discussed his company’s Boost converter, which, when combined with current sources, serves as a high-performance LED driver for vehicular LCD modules. The Boost, Chang said, can accommodate the wide input voltage range common in vehicular applications and deliver a wide dimming range.

Kevin Kruse (Osram Opto Semiconductors) discussed the benefits of direct-matrix local area dimming (or dynamic backlighting) for vehicular applications. The benefits, now familiar in TV displays but not yet in vehicular displays, include improved efficiency, high dynamic range, and reduced glare during low ambient. Kruse stressed that local dimming “enhances image contrast to compete with emerging OLED display technology” at a cost that will “still be competitive with conventional LCD backlight designs.”

Along with detailed discussions of performance and cost, Kruse described his company’s use of “segment cells” (think of an ice-cube tray without a bottom). The cells separate the LEDs and “improve light confinement and image contrast. Black levels observed with segment cell walls were barely discernable from the surrounding black chassis.” The segment cell prototype has thick walls which make the cell pattern visible, but production versions will have thinner walls, Kruse said.

3M Improves its Light Control Film

3M’s Nicholas Johnson described his company’s new light control film (LCF) concept, which improves on 3M’s current ALCF-A3+ product. The two technologies take difference approaches to blocking light from the instrument color that would otherwise reflect off the windshield while passing light directed toward the driver.

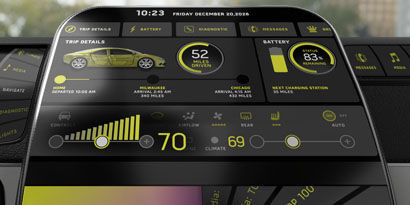

The current approach is a louver film, which has a very limited design range over which the louvers can be tilted to adjust the position of the pattern without excessive light loss. The new film has a broad range of both angular and spatial adjustment, which permits, for instance, a collimated light patern for the instrument cluster and a broader distribution for the center stack. The effect can differ at different locations on the display, so multiplexed images can be sent to different parts of the same display for driver and passenger.

3M sees its light control film being used on automotive centre stacks. Image:3M

3M sees its light control film being used on automotive centre stacks. Image:3M

Flexenable Working With Truly on OTFT

Simon Jones, Commercial Director of FlexEnable (Cambridge, UK) discussed his company’s work on flexible organic LCDs on plastic and their application to automotive HMIs. Although the company was founded in early 2015, its roots go back to 2000 with the founding of Plastic Logic, which was spun out of Cambridge University. FlexEnable’s piece of the technological puzzle is an organic TFT backplane, which must be combined with a polymer-based LC front plane to make a complete flexible LCD.

Jones said that in 2014 OTFT mobility exceeded that of a-Si. Mobility is now at 3, compared to a-Si’s remaining at 0.5 “So anything you can do with a-Si, you can now do with OTFT.”

FlexEnable has licensed its technology to the large Chinese panel maker Truly, which is a well-established supplier to the automotive industry. The bend radius with “conventional” plastic LCDs is 20mm today. FlexEnable and Merck have agreed to to combine the FlexEnable backplane with Merck’s polymer wall flexible LCD structure, which, said Jones, “will allow more aggressive bending.”

One application for flexible LCDs is an A-pillar display that will allow the driver to “see behind” the pillar, as has been demonstrated in Yanfeng’s XiM17 concept car. The A pillar would also be a good place to put the display for a digital side-view mirror.

The Yanfeng concept puts a display in the “A” pillar.

Truly intends to begin delivering modules for qualification in mid to late 2018.

Screen Laminatech (previously named FUK prior to its recent acquisition by Screen Finetech Solutions) makes production equipment for curved surface lamination and also certifies materials and components (such as OCA, glass, resins, and displays) as being compatible with its process. The company says its “curved display ecosystem is open to any firms seeking the same goal,” which is presumable to manufacturing of reliable curved displays. The company’s process and ecosystem have been used to fabricate FlexEnable prototypes, among others. “Curved displays are ready to hit the market,” concluded Screen Laminatech’s Takeshi Mori.

Finally, as far as this article is concerned, Marshall Paterson (VP of New Product Development for Advanced Decorative Systems) discussed the power of interior design to differentiate automotive products. Paterson is fond of American cars of the 1950s with their use of bright interior colors. In the modern era, he said, both color and texture are under-utilized to differentiate car interiors.

He noted that it was in 1977 that backlit plastic dials first began to replace flood-lit metal.

He said that designers fought to bring three-dimensional surfaces car interiors, but the flatness of displays has forced us to step backwards. He is very much in favor of curved displays and surfaces, into which controls can be integrated. He concluded:

“Let’s make things that are beautiful and distinctive.”

The Conference in 2018

The organizers anticipate continuing growth for 2018, and are discussing the addition of exhibit booths to the table-top displays that have been the only option until now. This unique display and HMI conference, one of the most stimulating on the calendar, deserves its growth and success.

Ken Werner is Principal of Nutmeg Consultants, specializing in the display industry, manufacturing, technology, and applications, including mobile devices and television. He consults for attorneys, investment analysts, and companies re-positioning themselves within the display industry or using displays in their products. He is the 2017 recipient of the Society for Information Display’s Lewis and Beatrice Winner Award. You can reach him at [email protected].