The final keynote speaker was Dr In Byeong Kang, Senior VP and CTO of LG Display, and his topic was ‘the challenges and opportunities of the display market’.

First, he looked back into the history and he pointed out that CRT production was 200 million units in 2000, but by 2014, the FPD industry was three billion displays – a 15 times increase. The big challenge for the industry was to make the panel flat. Finally, LCD won the battle of technologies.

From 1995, the IBM was 10.4″ with VGA and 100ips. This is an amazing contrast to today’s high end panels. Viewing angle, large size and high resolution were all challenges.

IPS LCD is becoming a unifying technology between IT and TV products. 19″ monitors were an early target for growing LCD volume and there were big problems with LC injection, which took almost a full day, but the monitors even thought the brightness was just 200 cd/m² and a $3,000 price. One drop fill was a big breakthrough to speed up the process and LG claims to have done this first.

The second challenge was to scale up sizes. The competition was from PDP which could make big panels. Key technology challenges were to develop copper bus technology and to solve mura and response time. Fab expansion developed to G7 and G8 (and G10 from Sharp). Now, LCD is the dominant TV display.

The third challenge was to introduce high resolution for small devices. Key breakthroughs were to increase transmission, add a new UV alignment technology and add in cell touch. There is tough competition for OLED in this application.

Now there are great displays with high resolution and good brightness.

The market has grown enormously, but now there is very little revenue growth, with a CAGR of just 0.7% to 2020. Despite this limited revenue growth there is a lot of capacity growth planned and that may lead to a depressing period of over capacity.

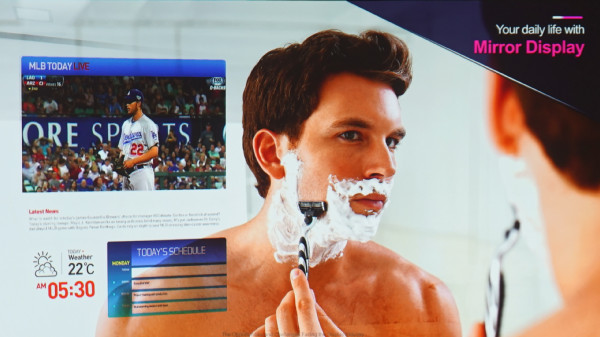

Kang then showed a short video of LG’s concept of the future which involved displays everywhere.

Key words are bendable, flexible, foldable and transparent with excellent video quality and the answer could be OLED because of the flexibility.

LG has been developing OLED since 1997 and in TV, LG has WOLED with oxide TFT and, for small sizes, RGB OLEDs with LTPS TFTs.

Challenges in creating flexible OLEDs include reducing the bend radius and improving the reliability. There is still a lot to do for flexible success.

LG has a new desk concept based on flexible displays

LG has a new desk concept based on flexible displays

To reduce the radius, you have to reduce the thickness of the OLED. By switching from glass to plastic you can reduce thickness by 40% but there is still more to go. Folding can cause accumulated structural stress and the cover window, polariser and touch also need to be flexible.

On the booth, LG was showing a curved 55″ OLED which used a glass substrate but a second OLED is 18.1″ diagonal and made with plastic which makes it reliable.

Transparent display is a challenge, and all technologies have a long way to go to achieve good results. There need to be improvements in transmission. You need to make the display non-transparent using an optical shutter so that black is properly shown and Kang said that also focus can be a problem.

Transparent displays also have to be low reflectance as well as having clarity and transparency.

Finally, even if you can make the display components, you need to get them integrated into sets and you need new applications and user interfaces.

To create new applications, the ecosystem needs to expand beyond materials and components into the application areas such as automotive, furniture and others.