We had a tour of the LG Display booth that started with a look at the latest 55″, 65″ and 77″ UltraHD OLED TV panels. There is no question that the visual performance of these panels is very impressive, although we worry that the lack of volume on OLED TV will make life very hard to compete and the technology may suffer as TV panels move to HDR. It was noticeable that LG Display didn’t show any LCD-based TV panels.

One of the highlights on the booth was an 18″ flexible top emission OLED with 1200 x 810 resolution and that used oxide TFTs to produce 300 cd/m² of brightness. Thickness was just 180 μm and the panel could be bent to a 30R (3cm). RGB patterning (in contrast to the white OLED approach used on LG’s TV panels) and a polyimide substrate were used, along with thin film encapsulation. LG presented a paper on the display in which it said that it expected to push the size up to 55″ by 2017. It said that the display was made on glass and the plastic released from the glass using a laser. Bending is said to have been tested 100,000 times.

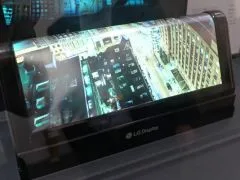

LG has been developing transparent panels such as those used in fridge doors for some years, and was showing the latest 55″ version on the booth. This is using a new subpixel structure that LG calls Ultra M+. The transparent panels have always used RGBW, but now the company has extended this to RWGWBW in a staggered pattern. This increases the aperture ratio, so the panel is claimed to get to 29% transmission by increasing the level of white pixels to 50%. Colour gamut is 68%, but it wasn’t clear – 68% of what? We believe this to be of NTSC. Staff told us that the gamut is the same as regular RGB panels because “we turn off the white pixels when we measure it”.

![]()

Next we looked at a 12.3″ FullHD (1920 x 720 16:6 aspect 167ppi) plastic RGB OLED that is designed for automotive applications. As with the 18″, this was made using RGB OLEDs and an LTPS backplane. Brightness is 600 cd/m² and contrast is quoted at 100,000:1. Curvature is quoted at 350R, which we took to be 350mm radius. It looked very good and mass production is planned for 2018.

Also for automotive applications was a 21.5″ 16:3 3840 x 720 curved LCD designed for cluster + CID integration. It has a radius of 2000R and brightness of 800 cd/m². Unfortunately, the sample seemed to have been damaged in transit and wasn’t working.

We reported on LG’s N-type LC material and UV-alignment technology at CES earlier this year. At SID, LG was emphasising that these two technologies allowed a 5.5″ FullHD panel to be made with a-si rather than polysilicon. Power consumption drops from 870mW to 682mW as the transmittance increases by 15%. This version should be available from Q4 2015.

Other new products included a 7″ 800 x 480 a-Si-based touch panel using “Advance In-cell Touch” (AIT) to provide 120Hz operation. Signal to noise is said to be 10db better than an OGS solution, with better transmission, reduced reflection (3.5% down to 1.7%), and able to support glove touch. There is no need for a cover glass and there is no pattern to be visible. Availability in mass production is planned for Q2 2016.

Also with AIT was a 15.6″ a-Si FullHD panel for notebook applications. Colour is just 45% and brightness is 220 cd/m², with contrast of 80:1. Touch update is 120Hz and the panel will be in production shortly.

A 6″ AMOLED has 1280 x 720 resolution and wraps around the edge (like the Samsung Edge) which LG calls Active Bending. Brightness is 300 cd/m² and contrast 100,000:1 and colour is quoted at 100%. Weight is 7.2g without the cover glass and the bend can be as tight as 5mm.

Of course, the range would not be complete without showing a watch display and the company had the round display that is in the LG Electronics watch. This is an AMOLED with 320 x 320 resolution (245ppi) with 100,000:1 contrast and 300 cd/m² of brightness. Thickness is 0.558mm without cover and weight is 1.39 gms.